Request Demo

Last update 15 Jul 2025

Azodicarbonamide

Last update 15 Jul 2025

Overview

Basic Info

Drug Type Small molecule drug |

Synonyms ADA, HPH-116, NSC 674447 + [1] |

Target |

Action modulators, inhibitors |

Mechanism CD4 modulators(T-cell surface antigen CD4 modulators), CD8 modulators(Cluster of differentiation 8 modulators), HIV p7 inhibitors |

Therapeutic Areas |

Active Indication- |

Inactive Indication |

Structure/Sequence

Molecular FormulaC2H4N4O2 |

InChIKeyXOZUGNYVDXMRKW-UHFFFAOYSA-N |

CAS Registry123-77-3 |

Related

3

Clinical Trials associated with AzodicarbonamideJPRN-UMIN000015616

Biologic MateR clinical performance test for ADA and TCZ Efficacy prediction - Biologic MateR clinical performance test for ADA and TCZ Efficacy prediction

Start Date04 Nov 2014 |

Sponsor / Collaborator- |

NCT01500278

A Multicenter, Single-blind, Randomized Parallel-group Study to Assess the Short- and Long-term Efficacy of Certolizumab Pegol Plus Methotrexate Compared to Adalimumab Plus Methotrexate in Subjects With Moderate to Severe Rheumatoid Arthritis Responding Inadequately to Methotrexate

This study is conducted to evaluate the short (12 Weeks) and long term (104 Weeks) efficacy of Certolizumab Pegol compared with Adalimumab both in combination with Methotrexate (MTX) in the treatment of moderate to severe Rheumatoid Arthritis (RA) that is not responding adequately to MTX.

Start Date01 Dec 2011 |

Sponsor / Collaborator UCB Pharma SA [+1] |

EUCTR2007-000950-30-ES

Estudio piloto, doble ciego, aleatorizado, controlado con placebo, de dosis repetida, para la evaluación de la seguridad y la eficacia antiviral de HPH116 en pacientes infectados por VIH-1 que no hayan recibido tratamiento previoA pilot, double-blinded, randomized, placebo-controlled, repeated dose, assessing HPH116 antiviral safety and efficacy in naïve HIV-1 infected patients. - PoC

Start Date05 Sep 2007 |

Sponsor / Collaborator- |

100 Clinical Results associated with Azodicarbonamide

Login to view more data

100 Translational Medicine associated with Azodicarbonamide

Login to view more data

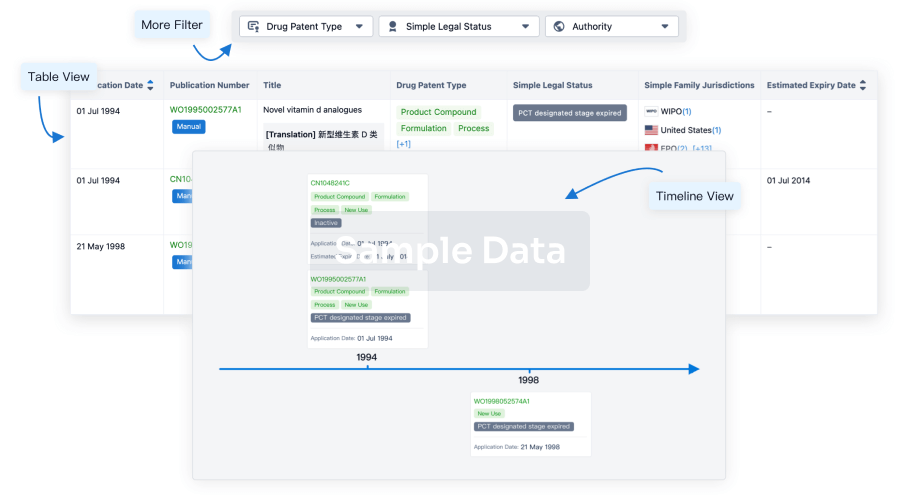

100 Patents (Medical) associated with Azodicarbonamide

Login to view more data

2,084

Literatures (Medical) associated with Azodicarbonamide01 Sep 2025·POLYMER DEGRADATION AND STABILITY

Effect of ACR/PMDA dynamic ion cross-linking network on dimensional stability and lightweight of PVC foam materials

Author: Liu, Jianqiao ; Zhang, Xu ; Xu, Ruilong ; Zhao, Shuai ; Zheng, Jiawang ; Song, Shikai ; Li, Lin ; Guo, Jingze

The mech. properties and dimensional stability of PVC foam materials are poor, which greatly affects their useful life and safety in the construction field.Therefore, we proposed a novel strategy that can effectively improve the dimensional stability of PVC foam materials.During the extrusion foaming process of PVC materials, the carboxyl group on the side chain of acrylic copolymer (ACR) and the hydrolyzed product of pyromellitic dianhydride (PMDA) occur ionic crosslinking between PVC mol. chains by consuming zinc acetate (Zn(OAc)2).The ion crosslinking network, ionic bond and -Cl ion dipole effect cooperates to limit the movement of the internal chain segments of PVC mol. chain when heated, thereby improving the dimensional stability of PVC foam materials.Compared with the standard PVC foam material, the longitudinal and transverse dimensional stability of PVC foam material with ion crosslinked network was improved by 56.0% and 53.3%, resp.In addition, the participation of Zn(OAc)2 in ion crosslinking reduced the d. of the material by 21.7%.This new strategy not only improves the dimensional stability of the material, but also improves the processing performance, which is expected to be extended to other foam materials.

01 Jul 2025·POLYMER ENGINEERING AND SCIENCE

Effects of combined azodicarbonamide and supercritical N2 foaming injection molding on cellular structure and mechanical properties of lightweight polypropylene products

Author: Yu, Shengrui ; Hua, Haitao ; Zhou, Huamin ; Zhang, Tianyu ; He, Linan ; Li, Haodong ; Xu, Lei ; Yu, Min ; Zeng, Lanyu ; Li, Qingzhou ; Han, Wen ; Chen, Fei

Abstract:

The increasing demand for lightweight, high‐performance polypropylene (PP) products has accelerated the development of foaming‐based injection molding technologies. The combined chemical foaming and microcellular injection molding (CF/MIM) process offers a promising solution by generating uniform cellular structures that enhance mechanical properties. However, achieving stable foaming remains challenging due to complex interactions between chemical blowing agents (CBAs) and physical blowing agents (PBAs). While previous studies have examined CBAs and PBAs separately, their combined effects on foaming efficiency, crystallization, and mechanical performance remain insufficiently explored. This study investigates the synergistic effects of azodicarbonamide (ADC), an exothermic CBA, and supercritical N2 (SC‐N2), a PBA, in CF/MIM. Compared to CFIM and MIM, CF/MIM with 1 wt% ADC and 0.10% SC‐N2 achieves equivalent foaming efficiency to CFIM with 2 wt% ADC and MIM with 0.38% SC‐N2. CF/MIM products exhibit an 11.53% increase in crystallinity, 5.61% higher tensile strength, and 5.99% greater flexural strength than CFIM. Additionally, CF/MIM promotes β‐crystal formation, enhances elongation at break by 26.28%, and reduces weight by 114.20% compared to MIM with 4 wt% ADC. These findings demonstrate that ADC and SC‐N2 significantly enhance CF/MIM performance, providing insights for optimizing lightweight, high‐strength PP manufacturing.

Highlights:

Improved ADC dispersion achieves a uniform cellular structure.Lower escape velocity of SC‐N2 forms a stable cell structure.Formed uniform and stable cellular structures enhance mechanical properties.Larger gas generation from ADC boosts weight reduction and foaming.

01 Jul 2025·POLYMER ENGINEERING AND SCIENCE

Preparation of mold temperature‐insensitive PP /LDPE foaming blends with lightweight and stable foaming performance

Author: Xing, Jinfu ; Wei, Zipeng ; Lei, Jie ; Zhang, Xiaodie ; Wu, Longna ; Zeng, Xiangbu ; Mu, Zhangqin ; Jiang, Tuanhui ; He, Li

Abstract:

Earlier research has demonstrated that the performance of foamed materials is heavily dependent on their foaming quality. In the process of injection molding foaming, changes in mold temperature frequently exert a significant influence on foaming quality. Consequently, it is essential to develop foaming materials that exhibit insensitivity to mold temperature. In this paper, mold temperature‐insensitive polypropylene/low density polyethylene (PP/LDPE) blends were prepared and chemically foamed at different mold temperatures. The study investigated cell morphology, rheological properties, crystallization characteristics, and mechanical performance of these blends. The findings revealed that PP30LDPE70(f) exhibited superior foaming quality compared to other blends across all tested mold temperatures. Specifically, PP30LDPE70(f)‐T60 showed a better foaming quality and mechanical properties. The cell density was 1.64 × 107 cells/m3, and the mean cell size was 17.69 μm. The foaming quality deteriorated as mold temperature increased. However, due to its diminished sensitivity to changes in mold temperature, PP30LDPE70(f) displayed a smaller variation in foaming quality. The molecular chain entanglement of PP30LDPE70 was particularly pronounced, resulting in a viscosity that remained relatively constant across varying cooling rates, demonstrating the insensitivity between foaming behavior and mold temperature.

Highlights:

A PP/LDPE blend with viscosity independent of cooling rate was prepared.PP/LDPE foam was prepared by chemical foaming at different mold temperatures.Materials with similar viscosity had better foaming quality.The molecular chain entanglement in PP/LDPE blends was evaluated.

2

News (Medical) associated with Azodicarbonamide07 Sep 2022

PARIS

— This weekend at ESMO, the KRAS battle between Amgen and its pesky biotech rivals at Mirati will continue with new slices of combo data for advanced cases of colorectal cancer. And once again, Mirati will get in with a solid punch.

Chuck Baum

Amgen has updated combination data on its approved pioneer Lumakras and its EGFR inhibitor Vectibix with a 30% overall response rate — way better than the meager 9.3% it posted earlier for the monotherapy.

But Mirati is in Paris touting adagrasib data in advanced colorectal cancer, with a 19% ORR on its own and a cetuximab (EGFR inhibitor Erbitux) combination cohort of 28 patients coming in at an improved 46% ORR — substantially superior on the snapshot.

Cowen’s Tyler Van Buren was among the first analysts to offer Mirati a thumbs up:

This is even more impressive considering that ada combo patients had a median of 3 prior lines vs. soto combo patients with 2. The CRC data continue to illustrate that ada is the superior option and a differentiated KRAS G12C inhibitor.

For Mirati founder Chuck Baum, it’s a solid add to the data set:

We continue to explore the full potential of adagrasib in combination with cetuximab in late-line CRC in a potentially registration-enabling Phase 2 cohort of theKRYSTAL-1 study and in second line CRC in the ongoing Phase 3 KRYSTAL-10 study.

Samuel Klempner

Amgen has dug in for the long run with its first-in-class player Lumakras, which has made biotech history in treating lung cancer by drugging the long “undruggable” KRAS. Now Mirati has been digging in its heels, looking for its first OK in lung cancer before the end of the year while trying to leapfrog the pharma giant in other arenas where Lumakras has struggled to make an impact. But they’re also testing investors’ patience as supporters wait for a clearer explanation of its filing plans.

Amgen, meanwhile, will have a presentation on its colorectal cancer data from its CodeBreaK 101 colorectal cancer study on Monday. Also on the radar is Roche’s GDC-6036, which looks like it’s coming in alongside Mirati’s drug for monotherapy results.

“These (Mirati) data illustrate the importance of durable KRAS inhibition in colorectal cancer and the added benefit that dual EGFR/KRAS blockade may provide for some patients in their regimen as evidenced by the more sustained responses from the adagrasib and cetuximab combination,” commented Samuel Klempner of the Massachusetts General Cancer Center and study investigator.

CollaborateFirst in Class

21 Jul 2022

With its five business units: Customised Polymer Materials (CPM), Masterbatches & Additives, Composite Materials, LUVOMAXX and Magnesia, the LEHVOSS Group will present the sustainability and performance of its materials at K 2022.

The LEHVOSS Group and its subsidiary WMK Plastics present sustainable materials from the LUVOTECH eco product line based on LEHVOSS ecX technology.

The materials in the LUVOTECH eco product line are based on raw materials from mechanical recycling and - as a further contribution to sustainability - are manufactured using 100 percent green electricity from a certified energy supplier.

The ecX technology (eco compounding eXperience) stands for know-how in the production of ecologically sustainable materials. This makes it possible to produce materials - from PC/ABS to PEEK-relevant applications - that have an improved CO2 balance sheet and a reduced overall environmental impact.

Characteristics of this recyclate product line are:

the careful analysis of the different starting materials,

the extensive knowledge related to adjustments in formulation,

gentle and material-compatible compounding,

the decades of experience in recycled materials of the LEHVOSS Group and its subsidiary WMK Plastics,

long-term contracts with established suppliers.

As a result, all materials in the LUVOTECH eco product line comply with the strict LEHVOSS quality guidelines and also have proven carbon footprints based on the internationally applicable standards and the determination using GaBI Professional software.

The LEHVOSS Group is meeting the growing demand for sustainable materials in 3D printing with the LUVOCOM 3F eco PET product line. The material consists of 90 percent recycled PET - the highest recycling rate currently known on the market.

LUVOCOM 3F eco PET can be used in both the FFF (Fused Filament Fabrication) and FGF (Fused Granulate Fabrication) processes. The areas of application include the production of functional prototypes and series parts in numerous industries. In addition to mechanical and automotive engineering, these also include medical technology.

Numerous other compounds are currently under development and will round off the product range in the short term.

The LEHVOSS Group presents a range of high-performance plastics as a metal alternative for the entire value chain in the field of bicycle components.

These plastics include:

high-strength materials with glass fibre and carbon fibre reinforcement for structural and add-on parts,

ultralight construction materials and high-performance materials for consistent lightweight construction with maximum strength,

tribologically optimised materials for minimising wear and friction or for dry running, and

technical recyclates to further reduce the environmental footprint.

All materials offer a metal alternative in terms of technical performance, component appearance and design freedom, as well as in terms of total cost and carbon footprint. They enable designers to exploit potentials - in terms of optimised component development, strength and weight - that were previously undiscovered or technologically unfeasible.

A series of end products will make the material advantages tangible at the LEHVOSS K 2022 trade show booth:

The FESCHD smartphone holder based on a plastic recyclate

As part of a production demonstration at the trade show booth, the LEHVOSS Group and FESCHD, a manufacturer of cell phone holders for bicycles from Gießen, Germany, will present the production of a smartphone holder. The holder is manufactured out of LEHVOSS recycled material LUVOTECH eco PA666-GF50-HS-BK.

A bicycle pedal crank manufactured based on the 3D skeleton wrapping technique (3DSW)

As part of the research project "Extreme Lightweight Design through Holistic Engineering of 3D Skeleton Wrapping Technology" (ELeGanz-3D), conducted jointly with the Fraunhofer Institute for Chemical Technology (ICT), the LEHVOSS Group is presenting a pedal crank for bicycles whose additively manufactured core consists of LUVOCOM 3F PAHT CF 9742 BK. The pedal crank demonstrator illustrates the potential of 3DSW in the context of lightweight applications requiring complex interactions of tensile, compressive and torsional loads.

The Klickfix bicycle accessories

The bicycle accessories of the Solingen-based manufacturer Rixen&Kaul have a consistent sustainability concept: This is based on the use of LUVOTECH eco materials - technical LEHVOSS recycling materials with optimised CO2 balance - and on the sourcing of materials from the LEHVOSS production site, which is also located in Solingen.

The Blobber bike saddle with air cushioning

This is completely produced in Austria. Up to 1.2 bar inflatable bicycle saddle with air damping has a printed core made of LUVOSINT TPU. The saddle is manufactured on the basis of two production processes: In the first step, the insert, which acts as a damping element, is sintered; in the second, polyurethane moulding technology is used.

Long-fibre-reinforced thermoplastics

Both in structural components and in the area of metal replacement, the new LFT compounds are said to be pushing forward into areas that were previously technologically unfeasible. The modifications presented at the trade show impress with their further optimised performance parameters, such as impact strength, colourability and surface properties. The trade show exhibits include:

The Elaflex aircraft refueling nozzle with optimised handle

The handle made of the mechanically highly stressable, impact-resistant material LUVOCOM LFT PA66-GF30 is based on a long-fibre-reinforced polyamide.

The Masterbatches & Additives division presents new high-performance additive masterbatches

The development of lightweight yet resistant plastics is an important topic for the future. After all, less weight means savings in energy, materials and transport costs. To achieve this goal, LUVOBATCH has developed physiologically safe, endothermic (azodicarbonamide (ADC)-free) blowing agent masterbatches for use in injection moulding and extrusion. These masterbatches can also be used in food applications and achieve results in reducing weight and sink marks and optimising processing parameters even at a low dosage - from 0.1 percent. In the automotive sector, for example, a weight reduction of 24 percent was achieved with a one percent masterbatch addition.

ADC

100 Deals associated with Azodicarbonamide

Login to view more data

R&D Status

10 top R&D records. to view more data

Login

| Indication | Highest Phase | Country/Location | Organization | Date |

|---|---|---|---|---|

| HIV Infections | Phase 2 | Spain | 02 Sep 2007 |

Login to view more data

Clinical Result

Clinical Result

Indication

Phase

Evaluation

View All Results

| Study | Phase | Population | Analyzed Enrollment | Group | Results | Evaluation | Publication Date |

|---|

No Data | |||||||

Login to view more data

Translational Medicine

Boost your research with our translational medicine data.

login

or

Deal

Boost your decision using our deal data.

login

or

Core Patent

Boost your research with our Core Patent data.

login

or

Clinical Trial

Identify the latest clinical trials across global registries.

login

or

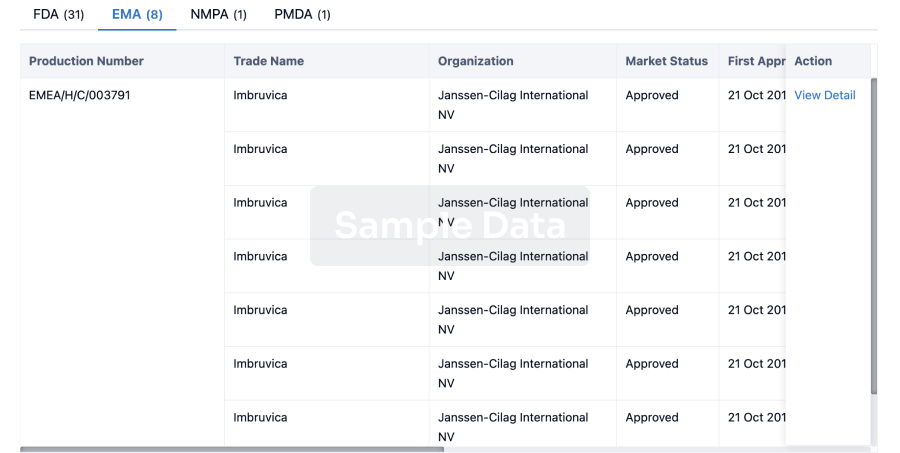

Approval

Accelerate your research with the latest regulatory approval information.

login

or

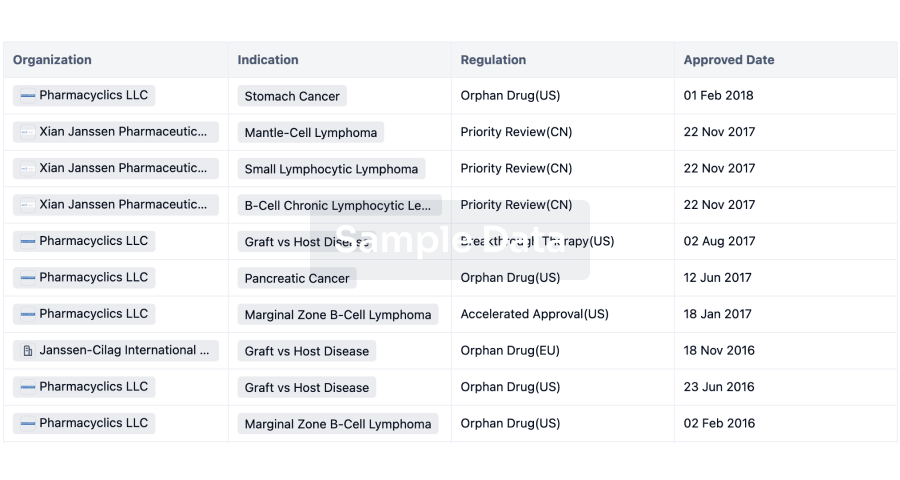

Regulation

Understand key drug designations in just a few clicks with Synapse.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free