Request Demo

Last update 08 May 2025

Phoenix Solutions Co.

Last update 08 May 2025

Overview

Related

1

Drugs associated with Phoenix Solutions Co.Target- |

Mechanism Macrophages stimulants |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication |

Drug Highest PhaseApproved |

First Approval Ctry. / Loc. European Union [+3] |

First Approval Date06 Mar 2009 |

100 Clinical Results associated with Phoenix Solutions Co.

Login to view more data

0 Patents (Medical) associated with Phoenix Solutions Co.

Login to view more data

5

Literatures (Medical) associated with Phoenix Solutions Co.Proceedings of the International Technical Conference on Coal Utilization & Fuel Systems

New materials and manufacturing options for low-cost candle filter production

Author: Shtessel, E. ; Decoursin, D. G. ; Hanus, G. J. ; Uznanski, K. T.

Proceedings, Annual Meeting - Air & Waste Management Association

A new generation of high-performance, low-cost candle filters

Author: Shtessel, E. ; Uznanski, K. T. ; Hanus, G. J.

Proceedings - Annual International Pittsburgh Coal Conference

Candle filter fabrication using combustion synthesis method

Author: Hickel, S. D. ; Decoursin, D. G. ; Hanus, G. J. ; Uznanski, K. T. ; Shtessel, E.

2

News (Medical) associated with Phoenix Solutions Co.19 Dec 2019

At the Drug Development Unit at The Institute of Cancer Research, London, and The Royal Marsden NHS Foundation Trust in London, the first patient in Phoenix’s first in human “ACTivate Trial” has received ACT® in combination with chemotherapy for treatment of hepatic metastases associated with colorectal and pancreatic cancer.

OSLO, Norway, December 18, 2019 (Newswire.com) -

At the Drug Development Unit at The

Institute of Cancer Research, London

, and The

Royal Marsden NHS Foundation Trust

in London, the first patient in Phoenix’s first in human “ACTivate Trial” (NCT04021277) has received ACT® in combination with chemotherapy for treatment of hepatic metastases associated with colorectal and pancreatic cancer.

CEO Dr. Per Sontum:

“We are extremely pleased to announce that Phoenix Solutions is now initiating the clinical development of ACT®. After six years of technical work and pre-clinical development with Prof. Jeff Bamber’s Ultrasound and Optics Team at the ICR, and Prof. Catharina de Lange Davies at The Norwegian University of Science and Technology, the transition to the clinical phase is a very exciting moment for all of us, team and collaborators.

We look forward to moving to the next phase of the ACTivate study whose goal is to evaluate the clinical benefits of ACT, then also including Haukeland and Oslo University hospitals as clinical sites.”

Vice-chairman Sir Bill Castell, who joined the board of Phoenix over a year ago, further comments:

“Whilst pursuing clinical development in combination with chemotherapy, we continue to explore with collaborators globally pre-clinical developments in new areas including cancer immuno-therapy, infectious diseases and enhancing drug delivery across the blood brain barrier. 2020 will be tremendously exciting in revealing the potential of ACT® as a technology platform… ".

Chief Investigator Prof. Udai Banerji, Deputy Head of Drug Development at The Institute of Cancer Research, London, and The Royal Marsden said:

“At our joint Drug Development Unit, we are very excited to start the clinical evaluation of ACT®. This represents an entirely novel approach to targeted drug delivery and is designed to significantly enhance the therapeutic efficacy of a number of chemotherapies used in the treatment of multiple cancers.”

The “ACTivate Trial” feature in BBC Breakfast, see:

The “ACTivate Trial” featured at ICR’s website, see:

The “ACTivate Trial” featured at RMH’s website, see:

About Phoenix Solution and ACT®

Phoenix Solutions AS is a privately held, Norwegian biotech company spun out from GE Healthcare, developing a proprietary technology platform for ultrasound mediated, targeted drug delivery - Acoustic Cluster Therapy (ACT®). ACT® comprises a unique microbubble /microdroplet formulation (PS101) for i.v. injection which, in combination with localized insonation with regular medical ultrasound, induces biomechanical effects that enable localized, controlled opening of the vascular barrier, leading to improved extravasation, distribution and uptake of co-administered drugs (e.g. chemotherapeutics) in the targeted tissues. Pre-clinical Proof of Concept studies have shown that ACT® improves markedly the efficacy of a wide range of therapeutic molecules and nano-drugs, in a wide range of disease models.

About the ACTivate Trial

ACTivate is a Phase I/Ib trial aimed to evaluate the safety and tolerability of ACT® (PS101 combined with local US insonation plus Standard of Care chemotherapy), for treatment of hepatic metastases from colon rectal and pancreatic cancer. Asides standard safety end points, the trial will evaluate the clinical efficacy of ACT® with the primary end point being a differential analysis of RECIST response by CT, between insonated and non-insonated lesions in the same patient after 8-12 weeks. Additional end points include DW- and DCE-MRI examinations. In addition to PS101 and ultrasound, patients with metastases from colon cancer will be dosed with standard regimens of either FOLFOX or FOLFIRI, whereas patients with metastases from pancreatic cancer will be dosed with nab-paclitaxel plus gemcitabine.

Colorectal cancer is the third most common cancer worldwide and approx. 30% of patients with CRC will develop liver metastases during the course of their disease. Only some 25% of these are amenable to curative-intent treatment through metastatectomy. For this disease, targeted treatment of hepatic metastases with ACT® has a range of potential applications including: as a part of a neo-adjuvant regime prior to resection to improve survival outcome, to downstage and increase the fraction of patients amenable for curative resection and, finally, to improve on survival outcome and palliation for non-resectable conditions.

About The Royal Marsden NHS Foundation Trust and The Institute of Cancer Research

The Royal Marsden opened its doors in 1851 as the world’s first hospital dedicated to cancer diagnosis, treatment, research and education.

Today, together with its academic partner, The Institute of Cancer Research (ICR), it is the largest and most comprehensive cancer centre in Europe seeing and treating over 50,000 NHS and private patients every year. It is a centre of excellence with an international reputation for groundbreaking research and pioneering the very latest in cancer treatments and technologies.

The Royal Marsden, with the ICR, is the only National Institute for Health Research Biomedical Research Centre for Cancer. This supports pioneering research work carried out over a number of different cancer themes.

The Royal Marsden Cancer Charity raises money solely to support The Royal Marsden, a world-leading cancer centre. They ensure their nurses, doctors and research teams can provide the very best care and develop life-saving treatments, which are used across the UK and around the world.

From funding state-of-the-art equipment and ground-breaking research, to creating the very best patient environments, they will never stop looking for ways to improve the lives of people affected by cancer.

The Institute of Cancer Research, London, is one of the world’s most influential cancer research organisations.

Scientists and clinicians at The Institute of Cancer Research (ICR) are working every day to make a real impact on cancer patients’ lives. Through its unique partnership with The Royal Marsden NHS Foundation Trust and ‘bench-to-bedside’ approach, the ICR is able to create and deliver results in a way that other institutions cannot. Together the two organisations are rated in the top four centres for cancer research and treatment globally.

The ICR has an outstanding record of achievement dating back more than 100 years. It provided the first convincing evidence that DNA damage is the basic cause of cancer, laying the foundation for the now universally accepted idea that cancer is a genetic disease. Today it is a world leader at identifying cancer-related genes and discovering new targeted drugs for personalised cancer treatment.

A college of the University of London, the ICR is the UK’s top-ranked academic institution for research quality and provides postgraduate higher education of international distinction. It has charitable status and relies on support from partner organisations, charities and the general public.

The ICR’s mission is to make the discoveries that defeat cancer. For more information visit

Disclaimer

This media statement contains certain forward-looking statements relating to the business, financial performance and results of Phoenix Solutions AS, their proprietary ACT technology, the ACTivate trial and/or the industry in which it operates. Forward-looking statements concern future circumstances and results and other statements that are not historical facts, sometimes identified by the words “believes”, “expects”, “intends”, “anticipates”, “targets”, and similar expressions. The forward-looking statements contained in this statement, including assumptions, opinions and views of the company or cited from third party sources are solely opinions and forecasts, which are subject to risks, uncertainties and other factors that may cause actual events to differ materially from any anticipated development. Neither the company nor any of its Directors, officers or employees provides any assurance that the assumptions underlying such forward-looking statements are free from errors nor does any of them accept any responsibility for the future accuracy of the opinions expressed in this statement or the actual occurrence of the forecasted developments.

The Company assumes no obligation, except as required by law, to update any forward-looking statements or to conform these forward-looking statements to our actual results.

Source: Phoenix Solutions

Clinical Study

04 Dec 2019

Phoenix Solutions AS, a clinical-stage biotech company, announced the appointment of Dr. Jean-Michel Cosséry to its Board of Directors.

OSLO, Norway, December 4, 2019 (Newswire.com) - Phoenix Solutions AS

, a clinical-stage biotech company, today announced the appointment of Dr. Jean-Michel Cosséry

to its Board of Directors.

“We are very pleased to welcome Dr. Jean-Michel Cosséry to the Board of Phoenix,” says Dr. Per Sontum, CEO of Phoenix. “Jean-Michel has a unique combination of experience spanning across diagnostics and therapeutics, with global leadership roles within research, marketing and commercialization in leading healthcare organizations. His knowledge of the field of oncology will be invaluable to Phoenix and we look forward to Jean-Michel’s contribution to the strategic, clinical and commercial development of our proprietary Acoustic Cluster Therapy technology (ACT®).”

Jean-Michel comments, “I am delighted to join the Board of Phoenix at the stage when the company has already taken its first steps into clinical development within oncology. Within this field, there is a range of unmet clinical needs and I believe increased, localized delivery of cytotoxic drugs can make a significant difference in many of these. I also see great potential for ACT® in the treatment of local pathologies within a range of other therapeutic areas.”

About Dr. Jean-Michel Cosséry

Jean-Michel is a senior healthcare executive with global leadership experience in research, marketing and commercial roles within med-tech and pharmaceuticals in six countries. Jean-Michel worked in Novartis and Serono before joining GE Healthcare (“GHEC”) as the Chief Marketing Officer and Vice-President Global Marketing. He represented GEHC at the GE Commercial Council and he was a member of the board for the Wipro-GE Healthcare joint venture in India.

More recently, Jean-Michel was with Eli-Lilly acting as Vice-President, North American Oncology, as well as Managing Director Northern Europe (including the U.K. and Ireland). Externally, Jean-Michel represented Lilly in the CEO Forum in Washington, D.C., was a board member of the ABPI and the Chairman of the Board of the American Pharmaceutical Group.

Today, Jean-Michel serves as a Non-Executive Director on the boards of Malin Corporation plc, Kymab Ltd and Immunocore Ltd.

Jean-Michel holds an MBA from the Rotterdam School of Management (Erasmus University), The Netherlands. He received his Ph.D. with honors in Nuclear Chemistry and Neurobiology from University Paris, France, and conducted post-doctoral research in Neuropharmacology at the NIH in the United States. Additionally, he holds a Pharm D with honors in Pharmacology from the University of Paris.

About Phoenix Solutions AS

Phoenix Solutions

is a clinical-stage Norwegian biotech company spun out of GE Healthcare in 2012, currently developing a technology platform for targeted drug delivery – Acoustic Cluster Therapy (ACT®). ACT® is a unique approach to ultrasound-mediated, targeted drug delivery – capable of enhancing significantly the clinical utility of a wide range of therapeutic molecules and nano-drugs for a wide range of clinical indications. Its primary mode of action is in defeating the vascular barrier, enhancing extravasation, distribution and uptake of drug in the targeted tissue, thereby increasing efficacy and/or reducing toxicity.

ACT® is generally indicated towards diseases where current clinical practice treats known, localized pathologies (e.g., solid tumors) with medicinal therapy, and where Standard of Care is being limited from an inability to deliver sufficiently high concentrations of drug without excessive systemic toxicity.

ACT® has shown extremely promising results in a series of pre-clinical evaluations, including treatment of colon, breast, pancreatic and prostate cancers, with a wide range of cytotoxic drugs. Phoenix is currently pursuing pre-clinical development exploring synergies between ACT® and immune-oncology drugs as well as within other medicinal segments such as CNS and infectious diseases.

Phoenix is currently in clinical development within the oncology segment at The Royal Marsden Hospital (U.K.). In their First in Man “ACTivate”-trial (NCT04021277), ACT® is investigated in combination with Standard of Care chemotherapies for treatment of hepatic metastases associated with colorectal and pancreatic cancers.

Disclaimer

This media statement contains certain forward-looking statements relating to the business, financial performance and results of Phoenix Solutions AS, their proprietary ACT technology, the ACTivate trial and/or the industry in which it operates. Forward-looking statements concern future circumstances and results and other statements that are not historical facts, sometimes identified by the words “believes,” “expects,” “

intends,” “anticipates,” “

targets,” and similar expressions. The forward-looking statements contained in this statement, including assumptions, opinions and views of the company or cited from third-party sources are solely opinions and forecasts, which are subject to risks, uncertainties and other factors that may cause actual events to differ materially from any anticipated development. Neither the company nor any of its Directors, officers or employees provide any assurance that the assumptions underlying such forward-looking statements are free from errors nor do any of them accept any responsibility for the future accuracy of the opinions expressed in this statement or the actual occurrence of the forecasted developments.

The Company assumes no obligation, except as required by law, to update any forward-looking statements or to conform these forward-looking statements to our actual results.

Media Contact:

CEO Dr. Per Christian Sontum

Email:

per.sontum@

phoenixsolutions.no

Executive Change

100 Deals associated with Phoenix Solutions Co.

Login to view more data

100 Translational Medicine associated with Phoenix Solutions Co.

Login to view more data

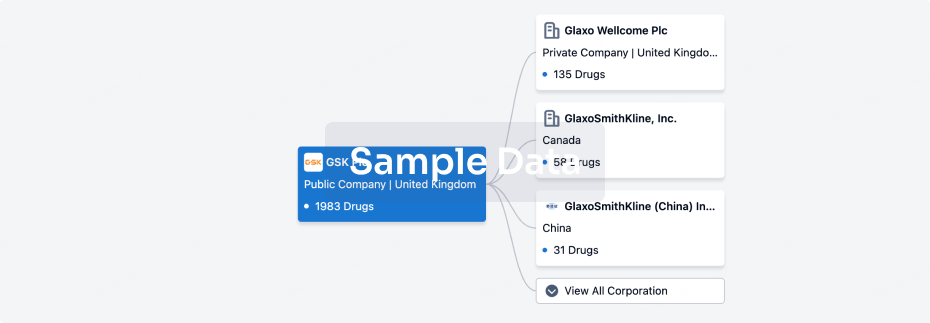

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 06 Mar 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Other

1

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

Mifamurtide | Colorectal Cancer More | Pending |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

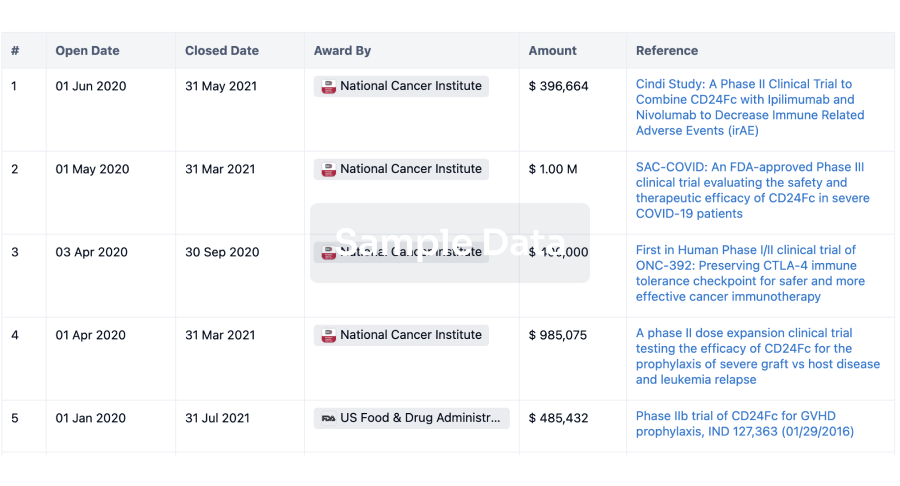

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free