Request Demo

Last update 08 Dec 2025

Davis

Last update 08 Dec 2025

Overview

Related

100 Clinical Results associated with Davis

Login to view more data

0 Patents (Medical) associated with Davis

Login to view more data

7

News (Medical) associated with Davis28 Feb 2023

Services to be Sustained for the Community

MOORESVILLE, N.C., Feb. 28, 2023 /PRNewswire/ -- Novant Health has signed a definitive agreement to acquire Lake Norman Regional Medical Center, Davis Regional Medical Center and their related businesses, including physician clinic operations and outpatient services from subsidiaries of Community Health Systems, Inc. (NYSE: CYH).

"Our shared commitments to the community will continue to anchor our efforts and plans as we deliver exceptional, patient-centered experiences; protect safety and quality; improve community health; and promote equitable access to care," said Carl S. Armato, president and CEO of Novant Health. "This unique and exciting opportunity to extend Novant Health's regional delivery network to new communities also creates opportunities for medical education, research and innovation."

The transaction is subject to regulatory approvals and is expected to close later this year.

"Novant Health has a demonstrated commitment to delivering quality care to the patients they serve across the communities they serve," said Matthew Littlejohn, Chief Executive Officer of Lake Norman Regional Medical Center and Davis Regional Medical Center. "Our tradition of serving the community with medical services close to home will be enhanced thanks to the dedication and skill of our medical staff and employees."

Once the transaction is complete, Novant Health will continue working with employees, members of the medical staff, and other stakeholders to deliver quality care close to home.

SOURCE Novant Health

Acquisition

10 Aug 2022

AR-701 is effective in vitro against SARS-CoV-2 Omicron subvariants, including BA.4 and BA.5

LOS GATOS, Calif., Aug. 10, 2022 /PRNewswire/ -- Aridis Pharmaceuticals, Inc. (Nasdaq: ARDS), a biopharmaceutical company focused on the discovery and development of novel anti-infective therapies to treat life-threatening infections, announced today that inhaled treatment of its fully human monoclonal antibody cocktail AR-701 resulted in no detectable SARS-CoV-2 virus in the lungs of infected rhesus macaques, and protected their lungs from disease. AR-701 was effective in the non-human primates when used either as a prophylactic or therapeutic treatment regimen.

Therapeutic administration of inhaled AR-701 substantially reduced and continued to suppress the viral load in the nasal sinus and oropharynx (upper respiratory tract region) for the entire 5-day testing period.

Additional lab research also indicates both mAbs in the AR-701 cocktail are effective against the SARS-CoV-2 Omicron BA.1, BA.2, BA.4, BA.5 subvariants in vitro.

This non-human primate research was conducted through a collective effort involving researchers at the Oregon National Primate Research Center (ONPRC) at Oregon Health & Science University (OHSU), the University of California at Davis, Vanderbilt University, the University of California at Irvine, and Aridis, with a grant supplement to OHSU from the National Institutes of Health's Office of Research Infrastructure Programs in the Office of the Director (OD, PHS grant P51 OD011092). Preliminary study results were recently presented at the Immunotherapy for Infectious Diseases Conference 2022 in Pavia, Italy. Additional data are being analyzed and will be submitted to a peer-reviewed scientific journal for publication.

"An efficacy demonstration in non-human primates has been a key milestone and a correlate for clinical success in human trials. The observed strong prophylactic and therapeutic efficacy bodes well for AR-701 and is an important step forward," commented Vu Truong, Ph.D., CEO of Aridis Pharmaceuticals. The proprietary inhaled formulation is designed to deliver the mAbs directly to the site where the SARS-CoV-2 virus initially infects, amplifies, and is transmitted from the infected individual to others. "Given the challenges in maintaining high vaccination coverage and a protracted COVID-19 pandemic, there is a greater need to develop accessible, long-acting therapeutic treatments, especially treatments that can also effectively block person-to-person viral transmission. These data demonstrate that the inhaled, self-administered dosage form of half-life extended AR-701 is on track to meet this product profile," said Truong.

About AR-701

AR-701 is a cocktail of two fully human immunoglobulin G1 (IgG1) mAbs discovered from screening the antibody secreting B-cells of convalescent SARS-CoV-2 infected (COVID-19) patients. Each mAb of the AR-701 cocktail neutralizes coronaviruses using a distinct mechanism of action, namely inhibition of viral fusion and entry into human cells (AR-703) or blockage of viral binding to the human 'ACE2' receptor (AR-720). The activity of the two mAbs complement and enhance each other in a synergistic fashion, creating a potent first-in-class cocktail. AR-720 binds to the 'receptor binding domain' of the spike protein of SARS-CoV-2, while AR-703 binds to the 'S2' stalk region of spike proteins from betacoronaviruses, including the SARS-CoV-2 variants (Beta, Gamma, Delta, Epsilon, and Omicron). Both mAbs bind to the Omicron subvariants, BA.1, BA.2, BA.4, and BA.5 with comparable affinity compared to the original Wuhan strain. All authentic live SARS-CoV-2 beta, gamma, delta, epsilon, and Omicron variants, SARS, and MERS tested were neutralized by both mAbs of AR-701 cocktail in vitro. Multiple animal challenge models widely used to evaluate COVID-19 treatments support the broad efficacy of AR-701 against the original Wuhan wildtype strain, the Delta variant, the Omicron variant, and the severe acute respiratory syndrome virus (SARS). The AR-701 mAbs are engineered to be active for 6-12 months in the blood. AR-701 is being developed as a long-acting intramuscular as well as a self-administered inhaled formulation for the treatment of COVID-19 patients who are not yet hospitalized. Aridis Pharmaceuticals recently received a grant from the Bill and Melinda Gates Foundation to evaluate the prevention of influenza and SARS-CoV2 viral transmission using inhaled delivery of monoclonal antibodies.

About Aridis Pharmaceuticals, Inc.

Aridis Pharmaceuticals, Inc. discovers and develops novel anti-infective therapies to treat life-threatening infections, including anti-infectives to be used as add-on treatments to standard-of-care antibiotics. The Company is utilizing its proprietary ʎPEXTM and MabIgX® technology platforms to rapidly identify rare, potent antibody-producing B-cells from patients who have successfully overcome an infection, and to rapidly manufacture monoclonal antibody (mAbs) for therapeutic treatment of critical infections. These mAbs are already of human origin and functionally optimized for high potency by the donor's immune system; hence, they technically do not require genetic engineering or further optimization to achieve full functionality.

The Company is advancing multiple clinical stage mAbs targeting bacteria that cause life-threatening infections such as ventilator associated pneumonia (VAP) and hospital acquired pneumonia (HAP), in addition to preclinical stage antiviral mAbs. The use of mAbs as anti-infective treatments represents an innovative therapeutic approach that harnesses the human immune system to fight infections and is designed to overcome the deficiencies associated with the current standard of care which is broad spectrum antibiotics. Such deficiencies include, but are not limited to, increasing drug resistance, short duration of efficacy, disruption of the normal flora of the human microbiome and lack of differentiation among current treatments. The mAb portfolio is complemented by a non-antibiotic novel mechanism small molecule anti-infective candidate being developed to treat lung infections in cystic fibrosis patients. The Company's pipeline is highlighted below:

Aridis' Pipeline

AR-301 (VAP). AR-301 is a fully human IgG1 mAb targeting gram-positive Staphylococcus aureus (S. aureus) alpha-toxin and is being evaluated in a global Phase 3 clinical study as an adjunctive treatment of S. aureus ventilator associated pneumonia (VAP).

AR-320 (VAP). AR-320 is a fully human IgG1 mAb targeting S. aureus alpha-toxin that is being evaluated in a Phase 3 clinical study as a preventative treatment of S. aureus colonized mechanically ventilated patients who do not yet have VAP.

AR-501 (cystic fibrosis). AR-501 is an inhaled formulation of gallium citrate with broad-spectrum anti-infective activity being developed to treat chronic lung infections in cystic fibrosis patients. This program is currently in Phase 2a clinical development in CF patients.

AR-701 (COVID-19). AR-701 is a cocktail of fully human mAbs discovered from convalescent COVID-19 patients that are directed at multiple protein epitopes on the SARS-CoV-2 virus. It is formulated for delivery via intramuscular injection or inhalation using a nebulizer.

AR-401 (blood stream infections). AR-401 is a fully human mAb preclinical program aimed at treating infections caused by gram-negative Acinetobacter baumannii.

AR-101 (HAP). AR-101 is a fully human immunoglobulin M, or IgM, mAb in Phase 2 clinical development targeting Pseudomonas aeruginosa (P. aeruginosa) liposaccharides serotype O11, which accounts for approximately 22% of all P. aeruginosa hospital acquired pneumonia cases worldwide.

AR-201 (RSV infection). AR-201 is a fully human IgG1 mAb out-licensed preclinical program aimed at neutralizing diverse clinical isolates of respiratory syncytial virus (RSV).

For additional information on Aridis Pharmaceuticals, please visit

Forward-Looking Statements

Certain statements in this press release are forward-looking statements that involve a number of risks and uncertainties. These statements may be identified by the use of words such as "anticipate," "believe," "forecast," "estimated" and "intend" or other similar terms or expressions that concern Aridis' expectations, strategy, plans or intentions. These forward-looking statements are based on Aridis' current expectations and actual results could differ materially. There are a number of factors that could cause actual events to differ materially from those indicated by such forward-looking statements. These factors include, but are not limited to, the need for additional financing, the timing of regulatory submissions, Aridis' ability to obtain and maintain regulatory approval of its existing product candidates and any other product candidates it may develop, approvals for clinical trials may be delayed or withheld by regulatory agencies, risks relating to the timing and costs of clinical trials, risks associated with obtaining funding from third parties, management and employee operations and execution risks, loss of key personnel, competition, risks related to market acceptance of products, intellectual property risks, risks related to business interruptions, including the outbreak of COVID-19 coronavirus, which could seriously harm our financial condition and increase our costs and expenses, risks associated with the uncertainty of future financial results, Aridis' ability to attract collaborators and partners and risks associated with Aridis' reliance on third party organizations. While the list of factors presented here is considered representative, no such list should be considered to be a complete statement of all potential risks and uncertainties. Unlisted factors may present significant additional obstacles to the realization of forward-looking statements. Actual results could differ materially from those described or implied by such forward-looking statements as a result of various important factors, including, without limitation, market conditions and the factors described under the caption "Risk Factors" in Aridis' 10-K for the year ended December 31, 2021 and Aridis' other filings made with the Securities and Exchange Commission. Forward-looking statements included herein are made as of the date hereof, and Aridis does not undertake any obligation to update publicly such statements to reflect subsequent events or circumstances.

Contact:

Media Communications:

Matt Sheldon

RedChip Companies Inc.

Matt@redchip.com

1-917-280-7329

Investor Relations

Dave Gentry

Redchip

Dave@redchip.com

1-800-733-2447

SOURCE Aridis Pharmaceuticals, Inc.

Company Codes: NASDAQ-NMS:ARDS

CollaborateFinancial StatementAntibodyFirst in ClassVaccine

29 Oct 2021

The 174,000 square-foot location will house a fully-equipped production plant to create its initial programs for Type 1 diabetes, a specific genetic cause of autism, galactosemia, and more.

Jaguar Gene Therapy

is establishing a large manufacturing facility in Durham, North Carolina, as part of plans to scale its clinical and commercial production.

The 174,000 square-foot location will house a

fully-equipped production plant

where the company will create its initial programs for Type 1 diabetes, a specific genetic cause of autism, galactosemia, and many more. The factory, reportedly worth more than $125 million, is located around 20 miles away from its existing Process Sciences Laboratory in Cary.

North Carolina is happy about this move, as the new facility is expected to create over 200 new jobs in the area over the next few years. Aside from receiving incentives worth over $7 million from local and state authorities, the company will also be getting over $2 million in funding over the next 12 years via the Job Development Investment Grant (JDIG). Also coming is a $100,000 partnership development grant from the North Carolina Biotechnology Center and $5 million in additional incentives from local and state organizations.

On top of future initiatives, the new Jaguar production center will also accommodate current contract development manufacturing organization (CDMO) partnerships and open up room for more third-party networks to guarantee uninterrupted supply and sourcing stability. The primary goal is to increase production yields while ensuring that product impurities stay low.

“This new state-of-the-art manufacturing facility, which will be augmented by our CDMO partnerships, will allow us to fully harness our team’s unparalleled CMC expertise as we aim to elevate the manufacturing of gene therapies. Patient safety is our top priority, and this facility will give us greater control of the manufacturing process to better ensure the highest purity level of our products,” said Andrew Knudten, M.S., MBA, the chief operating officer of Jaguar Gene Therapy.

In other news, Medford, Massachusetts, will also soon be seeing a boom in new facilities engaged in life sciences and biotechnology, with several major projects underway. These include RISE Together’s 250,000-square-foot biotech development at Mystic Valley Parkway, Oxford Properties’ 90,000-square-foot biomanufacturing plant at Sycamore Avenue, and Cumming Properties’ 37,000-square-foot expansion in Boston Avenue.

Davis Company’s 320,000-square-foot property at One Cabot Road is also expected to be converted into a life sciences facility soon, though this isn’t confirmed yet. The city is reportedly amending its zoning laws for industrial locations to encourage future development.

“This is exactly the kind of development that we as a city should be exploring... this type of development will greatly expand our commercial tax base and bring in hundreds of new jobs to Medford, providing many benefits to our residents and to our community as a whole,” commented Mayor Breanna Lugo-Koehn in a statement.

A similar level of excitement is also being felt at the

University of California, San Francisco

, following the

UCSF Joan and Sanford I. Weill Neurosciences Building

launch. The facility is preparing to house the world’s biggest and most comprehensive neuroscience centers where scientists and psychiatry, neurology, and neurosurgery clinicians can launch and maintain research programs for intractable brain diseases, among others.

“The UCSF Weill Neurosciences Building will stand as a beacon of hope, striving to push the frontier of what we know about the brain and expand the possibilities for effective treatments,” said S. Andrew Josephson, M.D., professor and chairman of the UCSF Department of Neurology and member of the new institute’s steering committee.

Aside from expansive research facilities, the 282,500-square-foot building will have specially designed clinical areas that can accommodate up to 450 patients per day. Funding for the facility came from a $185 million gift from Joan and Sanford I. Weill and the Weill Family Foundation in 2016. It is said to be one of the biggest donations to date for neuroscience in the U.S.

100 Deals associated with Davis

Login to view more data

100 Translational Medicine associated with Davis

Login to view more data

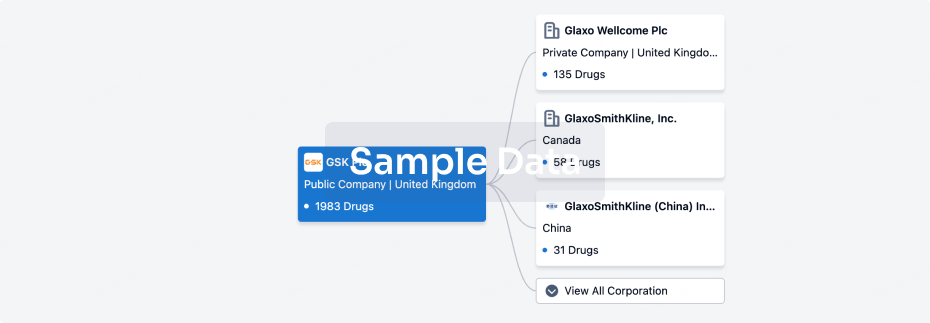

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 02 Mar 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Other

1

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

TP-70 ( APP ) | Diabetes Mellitus More | Pending |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

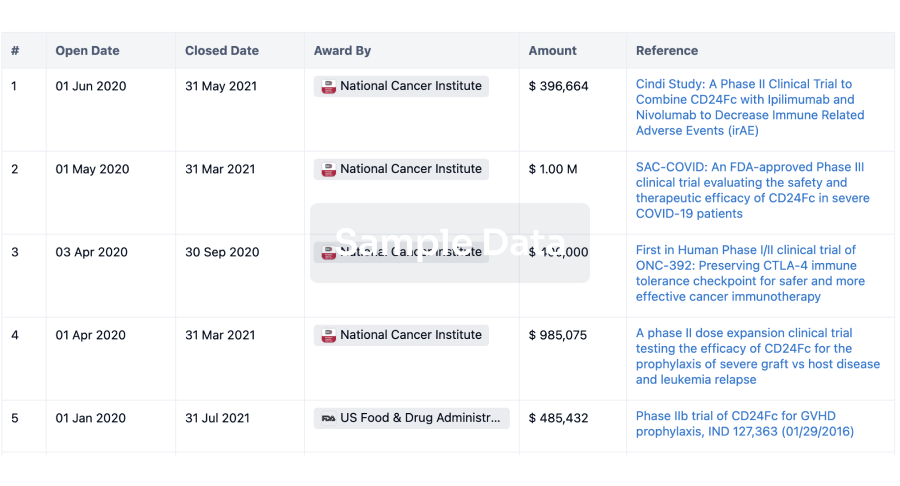

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free