Request Demo

Last update 08 May 2025

Inbrain Neuroelectronics SL

Last update 08 May 2025

Overview

Related

1

Clinical Trials associated with Inbrain Neuroelectronics SLNCT06368310

First in Human (FIH) Clinical Investigation of Safety and Feasibility of a Novel Graphene Micro-electrocorticography Array for Brain Mapping in Neuro-oncology

The goal of this clinical investigation of a medical device is to test the safety of graphene based electrodes when used during surgery for resection of brain tumors. The main questions that it aims to answer are:

To understand the safety of these new electrodes when used during brain tumor surgery (primary objective);

To assess the quality of the brain signals recorded with the new electrodes, their ability to stimulate the brain, how stable their function is over the duration of an operation, and their suitability for use in the operating theatre (secondary objectives).

Participants will undergo tumor surgery as usual with the study electrodes being tested alongside a standard monitoring system. If they are awake for part of their surgery they may be asked to complete specific tasks such as naming objects from a list modified for the study. They will be monitored subsequently for any complications including undergoing an additional MRI scan 6 weeks after their surgery.

To understand the safety of these new electrodes when used during brain tumor surgery (primary objective);

To assess the quality of the brain signals recorded with the new electrodes, their ability to stimulate the brain, how stable their function is over the duration of an operation, and their suitability for use in the operating theatre (secondary objectives).

Participants will undergo tumor surgery as usual with the study electrodes being tested alongside a standard monitoring system. If they are awake for part of their surgery they may be asked to complete specific tasks such as naming objects from a list modified for the study. They will be monitored subsequently for any complications including undergoing an additional MRI scan 6 weeks after their surgery.

Start Date28 May 2024 |

Sponsor / Collaborator |

100 Clinical Results associated with Inbrain Neuroelectronics SL

Login to view more data

0 Patents (Medical) associated with Inbrain Neuroelectronics SL

Login to view more data

12

News (Medical) associated with Inbrain Neuroelectronics SL02 Dec 2024

Graphene

is the novel material behind the brain-computer interface (BCI) technology developed by InBrain Neuroelectronics.

In 2020, Barcelona, Spain-based InBrain Neuroelectronics spun out of the Graphene Flagship, an EU research and innovation initiative focused on advancing graphene technology.

InBrain Neuroelectronics secured FDA breakthrough device designation for its system in 2023, with the goal of providing adjunctive therapy for Parkinson’s disease. In September 2024, the device developer launched a first-in-human study, making it the first time graphene has been implanted in a patient’s brain.

“We have a combination of a BCI cortical module [and] a high density subcortical module that come together in a skull-mounted device that actually decodes — in very high resolution — brain networks, and then can stimulate in micrometric resolution as well,” InBrain Neuroelectronics co-founder and CEO Carolina Aguilar said in a Medical Design & Outsourcing interview. “We call this BCI therapeutics (BCI-Tx), the fact that we can read and write — so decode and modulate — in high density and micrometric resolution.”

We asked Aguilar to share some of what she and her team have learned about graphene and its medtech applications. (We’ve lightly edited her responses for clarity and length.)

Graphene’s medtech advantages

Graphene’s “phenomenal” advantages are that it offers micrometric precision for sensing and stimulation, as well as biocompatibility and long-term stability, she said.

The reduced graphene oxide (rGO) that InBrain uses is essentially a stack of flakes, making it a very porous material.

“That porosity also makes the impedance quite low, and therefore the signal to noise ratio very, very high,” she said. “And on top of that, you can induce 200 times more charge density compared to metals. So that is a great advantage in our field, because, you can miniaturize … from 10 micrometers to maybe 1 mm — in our case, so far we use 25 micrometer ‘dots,’ we call them — and that gives you that sensitivity, that resolution, but also that density.”

That graphene contacts spacing as little as millimeters or micrometers yield more precise sensing and energy delivery than metals, where those contacts need at least 1 cm of space between them.

“That precision or that resolution gives you a lot of information of [certain] biomarkers, and understanding those biomarkers allows you to modulate them,” she said. “And on the modulation side, because it’s a non-metal, you don’t have these ferritic reactions that you have in metals, and it becomes a very, very stable material [for] stimulation or modulation. … It’s a critical factor to ensure stability and long-term reliability on the brain of someone for many, many years, 10 or 20 years.”

The technology has “endless applications” beyond neural sensors, including catheter technology and retinal implants.

“It allows you to not only find these biomarkers that sometimes with metals you cannot even see,” Aguilar said. “… Also, to modulate these fibers or these nuclei of the brain at that micrometric precision allows us to get a greater effectiveness, but also reduce side effects, because you are not spreading current around tissues [that] could actually generate different side effects. It is very important to understand which network of the brain you are really targeting and not to cause a lot of other side effects or stimulation in the non-targeted networks or areas.”

Another advantage of working with a material as thin as graphene is conformity. InBrain’s working with thicknesses of 10 to 12 micrometers, which “perfectly adapts to the tissue … like a second skin,” she said, without the stiffness of materials like silicon.

“And then, we have technology that allow us to multiplex so we can get 1,024 contacts with very few wires, which has been one of the one of the challenges in neurotechnology,” she said.

But it’s less about maximizing the number of contacts a device developer can put into a brain and more about the right number and placement of contacts for safe and effective treatment.

“In this field, there is a race to put as many contacts as you want or you think you need,” Aguilar said. “.. But I think it’s not about who can put more contacts on the surface of the brain. It’s more about what those contacts can do clinically in a relevant and meaningful way for the patient. We can not forget about that, because this is not a technology race.”

Medical graphene challenges

The most challenging part of working with graphene is sorting through the various types, configurations and suppliers.

“To make it biocompatible and stable for our application has been the target and the focus,” Aguilar said. “So making sure that the graphene we wanted was in the conditions and specifications we wanted, that it will be absolutely biocompatible, and that on top of that we could keep those properties that make it an ideal BCI interface — that required time. Before InBrain was founded, there were eight years of development for that.”

The Graphene Foundship (founded in 2013) conducted studies on biocompatibility before InBrain launched its preclinical testing for the U.K.’s Medicines and Healthcare products Regulatory Agency (MHRA), the FDA and ISO 13485.

“We got very good results from the very beginning, which reassured us big time,” she said.

Studies on graphene have even looked into the potential risks for people who inhaled graphene oxide nanosheets, including a first-in-human controlled study.

As research continues, graphene will one day become as accepted in medical devices as silicon or platinum-iridium is now, Aguilar said.

“This is something that is a long-term effort, and we will continue,” she said.

20 Sep 2023

The FDA’s BDD covers the graphene-neural platform as an adjunctive therapy for Parkinson’s disease by combining machine learning software that decodes therapy-specific biomarkers and ultra-high signal resolution

INBRAIN Neuroelectronics has developed a graphene-based, high-resolution cortical brain interface. (Credit: Business Wire)

Health technology company INBRAIN Neuroelectronics has received Breakthrough Device Designation (BDD) from the US Food & Drug Administration (FDA) for its Intelligent Network Modulation System.

The FDA’s BDD covers the graphene-neural platform as an adjunctive therapy for the treatment of Parkinson’s disease.

The INBRAIN system uses the two-dimensional substance graphene, which is formed of a lattice of carbon atoms that is only one atom thick.

According to the Spanish health technology company, graphene’s combination of electrical and mechanical properties is suitable for this neurotechnology innovation.

INBRAIN’s neural platform technology combines machine learning software that decodes therapy-specific biomarkers and ultra-high signal resolution.

The platform delivers highly focused, adaptive neuroelectronic therapy that rebalances pathological neural networks.

INBRAIN Neuroelectronics Clinical Affairs head Dan Gnansia said: “Breakthrough device designation from the FDA signifies the potential of the INBRAIN neural platform to further improve the lives of patients with Parkinson’s disease.

“We look forward to working with the agency to help bring this important advance into clinical practice.”

The INBRAIN system has been designated by the FDA as a Breakthrough Device, which entitles the manufacturer to feedback during the regulatory process and priority review by the FDA.

The company’s graphene-neural platform is a semiconductor-derived brain-computer interface (BCI) technology that can modulate and decode brain activity. It uses artificial intelligence (AI) to start adaptive reactions for customised neurological care.

INBRAIN Neuroelectronics CEO and co-founder Carolina Aguilar said: “INBRAIN is dedicated to leveraging new discoveries in materials science and transforming them into safe and effective breakthrough therapy applications.

“We anticipate developing our technology to treat other conditions affecting the central and peripheral nervous systems to make BCI technology relevant in neuro and bioelectronics.”

In July 2021, Inbrain Neuroelectronics teamed up with Merck to jointly develop the next generation of graphene-based bioelectronic vagus nerve therapies for severe chronic diseases.

Breakthrough Therapy

19 Sep 2023

First-of-a-kind system designed to offer new treatment option for patients with Parkinson’s disease

BARCELONA, Spain--(BUSINESS WIRE)-- INBRAIN Neuroelectronics S.L., a health-tech company dedicated to developing the world’s first intelligent graphene-neural platform, today announced that its Intelligent Network Modulation System has been granted Breakthrough Device Designation (BDD) from the U.S. Food & Drug Administration (FDA) as an adjunctive therapy for treating Parkinson’s disease.

This press release features multimedia. View the full release here:

INBRAIN graphene-based, high-resolution cortical brain interface © INBRAIN Neuroelectronics (Photo: Business Wire)

The INBRAIN system harnesses the power of graphene, a two-dimensional material made of a lattice of carbon atoms only one atom thick. The thinnest material known, yet stronger than steel, graphene’s unique combination of electrical and mechanical properties makes it ideal for neurotechnology innovation. INBRAIN’s neural platform technology enables ultra-high signal resolution at levels never seen before, and uses machine learning software that decodes therapy-specific biomarkers to deliver highly focused, adaptive neuroelectronic therapy that re-balances pathological neural networks.

“Breakthrough device designation from the FDA signifies the potential of the INBRAIN neural platform to further improve the lives of patients with Parkinson’s disease,” said INBRAIN Neuroelectronics Clinical Affairs Head Dan Gnansia. “We look forward to working with the agency to help bring this important advance into clinical practice.”

Breakthrough designation recognizes devices that represent a breakthrough or offer a reasonable proof of significant advantage over existing approved or cleared alternatives. It also expedites the development and FDA review of new devices with the potential to more effectively treat or diagnose life-threatening or irreversibly debilitating conditions.

“From the current available clinical brain interfaces, deep brain stimulation is a successful therapy to treat Parkinson’s disease. However, current leads have restrictions regarding their relatively large size and low density, limiting their precision for targeting of small deep structures such as the subthalamic nucleus (STN), and the spatial or signal resolution when sensing the local brain electrical activity,” said Helen Bronte Stewart, professor of neurology and neurological sciences at Stanford University School of Medicine. “INBRAIN’s new generation of ultrathin graphene-based high resolution interfaces and associated network platform may vastly improve the precision, efficiency and efficacy of DBS and closed-loop or adaptive modulation. The FDA breakthrough device designation is a statement to how this technology may be a paradigm shift in the scope of neuromodulation for people with Parkinson’s disease and hopefully for other neuropsychiatric diseases in the future.”

FDA recognition of the INBRAIN system as a Breakthrough Device means the company will receive feedback throughout the regulatory process, as well as prioritized review by the agency.

“INBRAIN is dedicated to leveraging new discoveries in materials science, and transforming them into safe and effective breakthrough therapy applications,” added Carolina Aguilar, INBRAIN Neuroelectronics CEO and co-founder “We anticipate developing our technology to treat other conditions affecting the central and peripheral nervous systems to make BCI technology relevant in neuro and bioelectronics.”

About INBRAIN Neuroelectronics

INBRAIN Neuroelectronics S.L., founded in 2020, is a health-tech company dedicated to developing the world’s first intelligent graphene-neural platform to treat a variety of conditions. INBRAIN develops semiconductors derived brain computer interface (BCI) technology that applied in neuromodulation is designed to decode and modulate brain activity in high resolution, using artificial intelligence to trigger adaptive responses for personalized neurological treatment in Parkinson’s disease, epilepsy and speech impairment. For more information, please visit , or find us on LinkedIn.

About INNERVIA Bioelectronics

INNERVIA Bioelectronics is a fully owned subsidiary of INBRAIN, dedicated to using graphene technology to develop an intelligent neural platform for peripheral nerve applications in collaboration with Merck KGaA (Darmstadt, Germany) in areas of Merck’s therapeutic interest.

Disclaimer: The INBRAIN Intelligent Network Modulation System is limited by Federal (or United States) law to investigational use only.

100 Deals associated with Inbrain Neuroelectronics SL

Login to view more data

100 Translational Medicine associated with Inbrain Neuroelectronics SL

Login to view more data

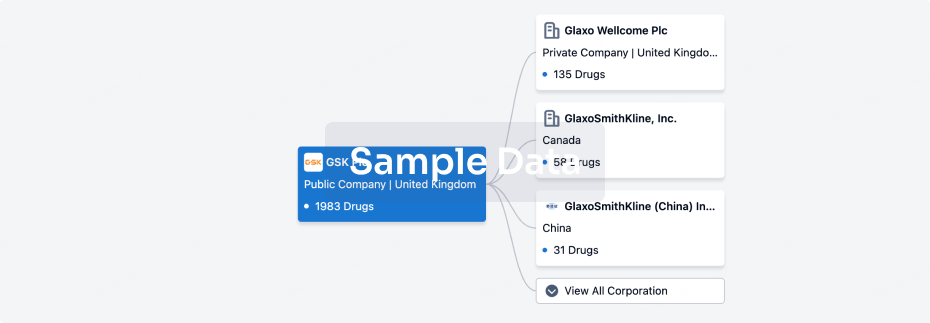

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 26 Feb 2026

No data posted

Login to keep update

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

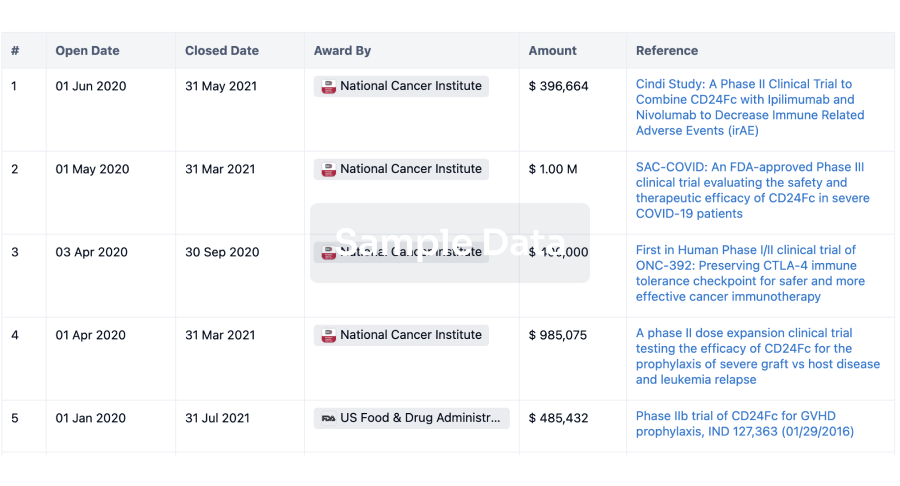

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free