Request Demo

Last update 23 Jun 2025

Outokumpu Srl

Last update 23 Jun 2025

Overview

Related

1

Clinical Trials associated with Outokumpu SrlNCT00821509

STOPFLU: Is it Possible to Reduce the Number of Days Off in Office Work by Improved Hand-hygiene?

Improved hand hygiene is known to reduce transmission of both respiratory (RTI) and gastrointestinal infections (GTI) under "semi-closed" conditions such as hospitals, day-care centres and schools. It is not known if similar interventions would have the desired effect in a regular office work. This study is aiming to investigate this possibility by recruiting volunteers from several companies in the Helsinki Region. The two intervention groups will receive detailed instructions e.g. for proper coughing and sneezing, and for regular cleaning of hands with either standard liquid soap or with alcohol-based gel rubbing. Third group will serve as the control and is advised not to change their previous behaviour in this respect. The participants will report weekly possible RTI or GTI symptoms and related days off through internet. The study is planned to run about 18 months to cover the seasonal variation of the epidemics of the causative different viruses.

Start Date01 Jan 2009 |

Sponsor / Collaborator |

100 Clinical Results associated with Outokumpu Srl

Login to view more data

0 Patents (Medical) associated with Outokumpu Srl

Login to view more data

11

Literatures (Medical) associated with Outokumpu Srl01 Mar 2016·MATERIALS SCIENCE AND ENGINEERING A-STRUCTURAL MATERIALS PROPERTIES MICROSTRUCTURE AND PROCESSING

Effects of reversion and recrystallization on microstructure and mechanical properties of Nb-alloyed low-Ni high-Mn austenitic stainless steels

Author: A.S. Hamada ; D. Porter ; A. Kisko ; J. Talonen ; L.P. Karjalainen

The influence of reversion annealing on the microstructure and mech. properties of an austenitic high-Mn low-Ni 15Cr-9Mn-1.1Ni-1.7Cu stainless steel with and without Nb alloying was investigated.The steel sheets were cold rolled to a 60% thickness reduction to obtain ∼60% of strain-induced α'-martensite and subsequently annealed at temperatures between 700 and 1100° for 0.1-1000 s to revert the α'-martensite back to austenite and recrystallize the retained austenite.Microstructure evolution was studied using x-ray diffraction, magnetic measurements, optical microscopy and electron backscatter diffraction techniques.Mech. properties were determined using microhardness measurements and tensile tests at room temperatureReversion could be completed at 700° but then recrystallization of the retained austenite remained partial.At 800°, a non-uniform grain structure was obtained consisting of ultrafine-grained areas formed via α'-martensite reversion and coarser ones by recrystallization of the retained austenite, whereas at 900° a uniform austenite grain size in the range of 1-2 μm was obtained for all the steels.The non-uniform grain structures exhibited excellent combinations of strength and ductility.The major contribution to the strength is attributed to the refined grain size.The strain hardening rate was higher for the Nb-free steel, even though strain-induced α'-martensite fractions after fracture were slightly lower than in the Nb-alloyed steels.

01 Oct 2014·METALLURGICAL AND MATERIALS TRANSACTIONS A-PHYSICAL METALLURGY AND MATERIALS SCIENCE

Effect of Internal Hydrogen on Delayed Cracking of Metastable Low-Nickel Austenitic Stainless Steels

Author: Juho Talonen ; Suvi Papula ; Olga Todoshchenko ; Hannu Hänninen

Metastable austenitic stainless steels, especially manganese-alloyed low-nickel grades, may be susceptible to delayed cracking after forming processes.Even a few wppm of hydrogen present in austenitic stainless steels as an inevitable impurity is sufficient to cause cracking if high enough fraction of strain-induced α'-martensite and high residual tensile stresses are present.The role of internal hydrogen content in delayed cracking of several metastable austenitic stainless steels having different alloying chemistries was investigated by means of Swift cup tests, both in as-supplied state and after annealing at 673 K (400 °C).Hydrogen content of the test materials in each state was analyzed with three different methods: inert gas fusion, thermal anal., and thermal desorption spectroscopy.Internal hydrogen content in as-supplied state was higher in the studied manganese-alloyed low-nickel grades, which contributed to susceptibility of unstable grades to delayed cracking.Annealing of the stainless steels reduced their hydrogen content by 1 to 3 wppm and markedly lowered the risk of delayed cracking.Limiting drawing ratio was improved from 1.4 to 1.7 in grade 204Cu, from 1.7 to 2.0 in grade 201 and from 1.8 to 2.12 in grade 301.The threshold levels of α'-martensite and residual stress for delayed cracking at different hydrogen contents were defined for the test materials.

01 Apr 2014·METALLURGICAL AND MATERIALS TRANSACTIONS A-PHYSICAL METALLURGY AND MATERIALS SCIENCE

A Stacking Fault Energy Perspective into the Uniaxial Tensile Deformation Behavior and Microstructure of a Cr-Mn Austenitic Steel

Author: D A Porter ; A S Hamada ; J Talonen ; S K Shee ; B Mahato ; T Sahu ; L P Karjalainen ; H Barman ; Puspendu Sahu

A Cr-Mn austenitic steel was tensile strained in the temperature range 273 K (0°) ≤ T ≤ 473 K (200°), to improve the understanding on the role of stacking fault energy (SFE) on the deformation behavior, associated microstructure, and mech. properties of low-SFE alloys.The failed specimens were studied using x-ray diffraction, electron backscatter diffraction, and transmission electron microscopy.The SFE of the steel was estimated to vary between ∼ 10 to 40 mJ/m2 at the lowest and highest deformation temperatures, resp.At the ambient temperatures, the deformation involved martensite transformation (i.e., the TRIP effect), moderate deformation-induced twinning, and extended dislocations with wide stacking faults (SFs).The corresponding SF probability of austenite was very high (∼10-2).Deformation twinning was most prevalent at 323 K (50°), also resulting in the highest uniform elongation at this temperatureAbove 323 K (50°), the TRIP effect was suppressed and the incidence of twinning decreased due to increasing SFE.At elevated temperatures, fine nano-sized SF ribbons were observed and the SF probability decreased by an order (∼10-3).High dislocation densities (∼1015 m-2) in austenite were estimated in the entire deformation temperature range.Dislocations had an increasingly screw character up to 323 K (50°), thereafter becoming mainly edge.The estimated dislocation and twin densities were found to explain approx. the measured flow stress on the basis of the Taylor equation.

2

News (Medical) associated with Outokumpu Srl21 Dec 2023

The Supervisory Board of BASF SE has nominated Tamara Weinert, president and CEO of Business Area Americas of Outokumpu, based in the United States, for election as shareholder representative on the Supervisory Board. The election is to take place at the Annual Shareholders’ Meeting of BASF SE on April 25, 2024.

Weinert is to succeed Dame Alison Carnwath, who will not stand for election to BASF’s Supervisory Board next year. Carnwath has been a member of BASF’s Supervisory Board since May 2014. She would therefore no longer considered to be independent according to the criteria of the German Corporate Governance Codex in the course of her mandate if she were to be re-elected for four years.

“With Tamara Weinert, we have been able to find an experienced and competent leader as a candidate for election to the Supervisory Board of BASF SE. She will strengthen the diversity and independence of the Board,” said Dr. Kurt Bock, chairman of the Supervisory Board of BASF SE.

Weinert began her professional career at Deutsche Bank, where she held various positions in Europe and Asia. Since 2021, Weinert is resident and CEO of Business Area Americas and member of the leadership team of Outokumpu. The company is a leading global supplier of sustainable stainless steel.

Executive Change

13 May 2019

Outokumpu Oyj

Stock exchange release

Manager transaction

May 13, 2019 at 4.45 pm EEST

Outokumpu – Manager transaction: Kari Jordan

Outokumpu has received a notification of a receipt of shares from Kari Jordan, member of the Board of Directors, according to the EU Market Abuse Regulation. According to the decision taken at the Annual General Meeting, 40% of the annual remuneration of the members of the Board of Directors will be paid in the Company’s own shares. Detailed information is given in the table below.

Name of the manager

Kari Jordan

Position in the issuer

Member of the Board of Directors

Issuer

Outokumpu Oyj

Issuer’s LEI reference

5493009YRUJJDCFF0R80

Notification type

Initial notification

Date of the transaction

May 9, 2019

Venue

Outside a trading venue

Nature of transaction

Receipt of a share-based incentive or remuneration

Instrument

Outokumpu share (OUT1V, ISIN: FI0009002422)

Transaction details

Volume: 21,087

Price: 0.00 (EUR)

Aggregated transactions

Volume: 21,087

Average price: 0.00 (EUR)

Total ownership of the instrument after the transaction

102,474 shares

For more information:

Corporate communications, tel. +358 9 421 3840

Outokumpu Oyj

Outokumpu is the global leader in stainless steel. We aim to be the best value creator in stainless steel by 2020, through our competitive edge of customer orientation and efficiency. The foundation of our business is our ability to tailor stainless steel into any form and for almost any purpose. Stainless steel is sustainable, durable and designed to last forever. Our customers use it to create civilization’s basic structures and its most famous landmarks as well as products for households and various industries. Outokumpu employs 10,000 professionals in more than 30 countries, with headquarters in Helsinki, Finland and shares listed in Nasdaq Helsinki.

www.outokumpu.com

100 Deals associated with Outokumpu Srl

Login to view more data

100 Translational Medicine associated with Outokumpu Srl

Login to view more data

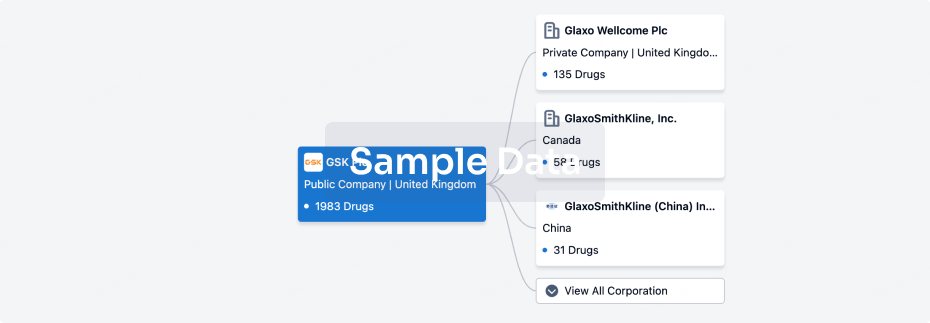

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 19 Jul 2025

No data posted

Login to keep update

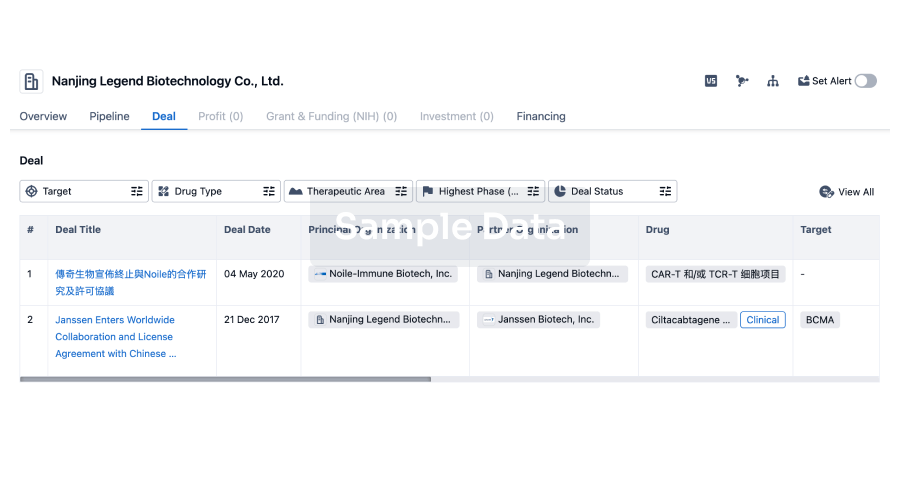

Deal

Boost your decision using our deal data.

login

or

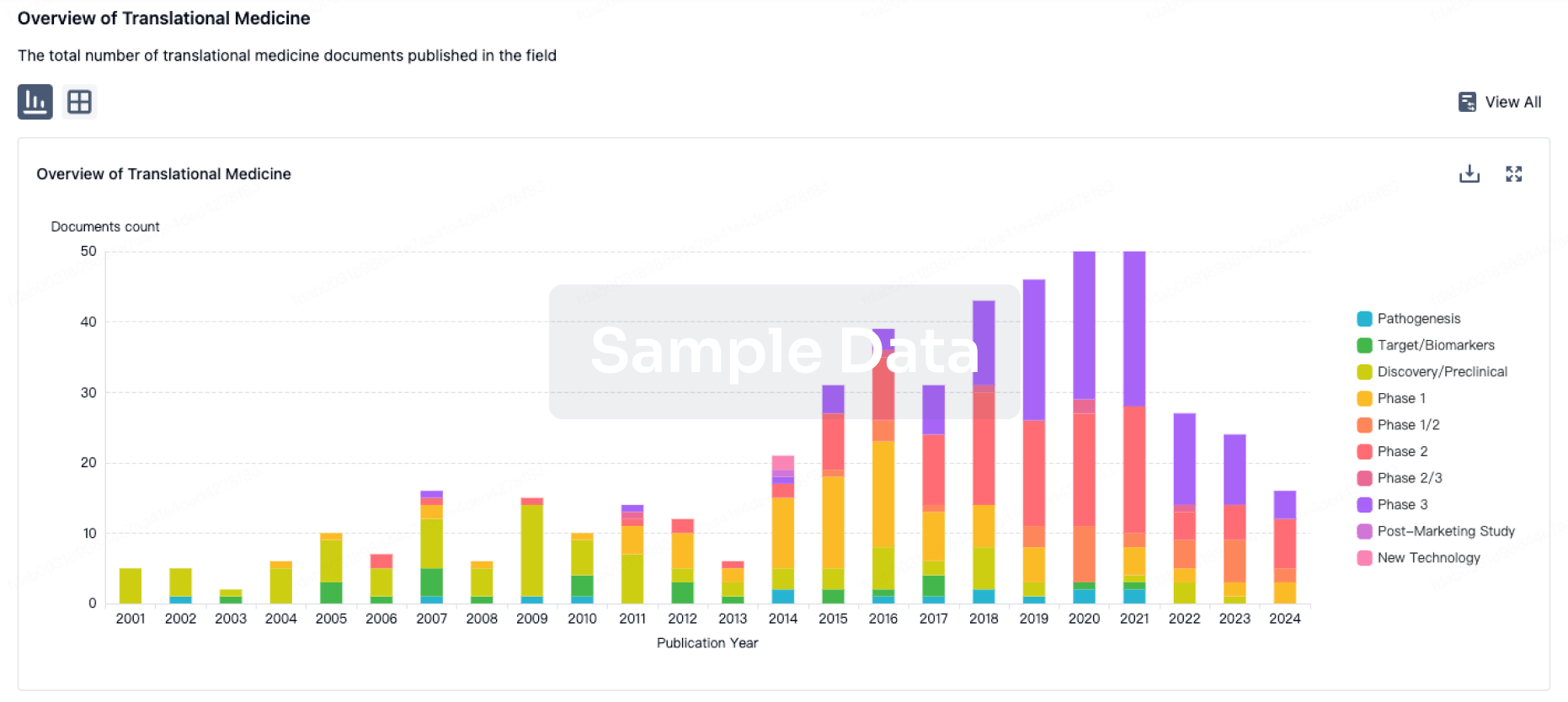

Translational Medicine

Boost your research with our translational medicine data.

login

or

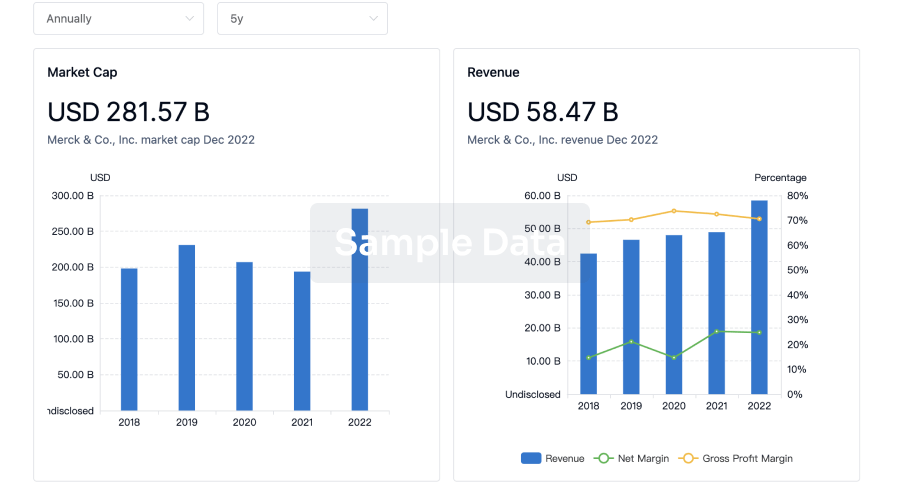

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

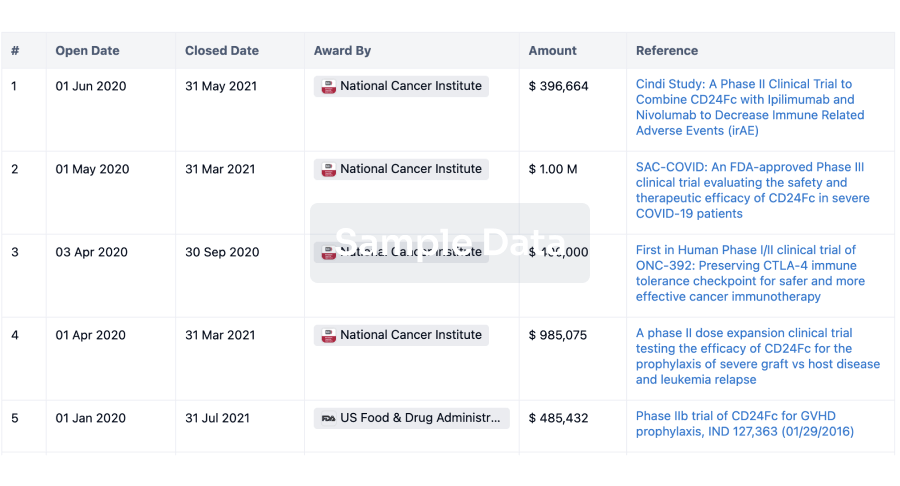

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

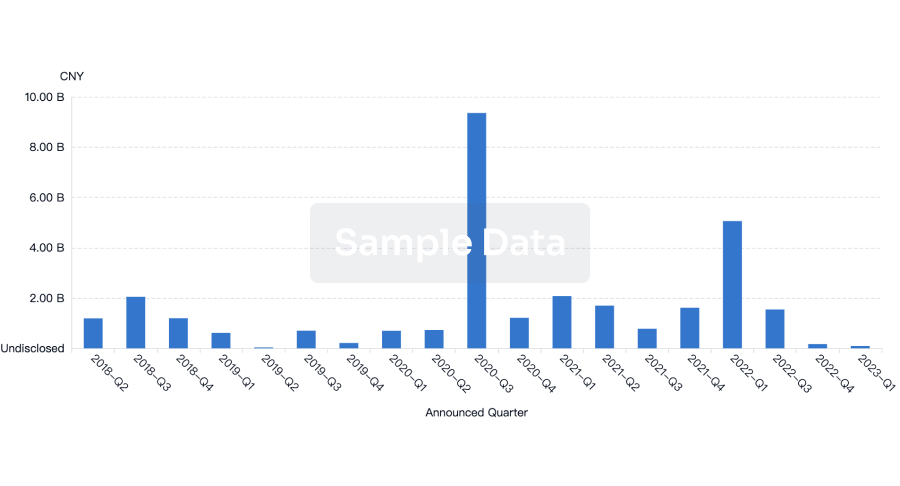

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

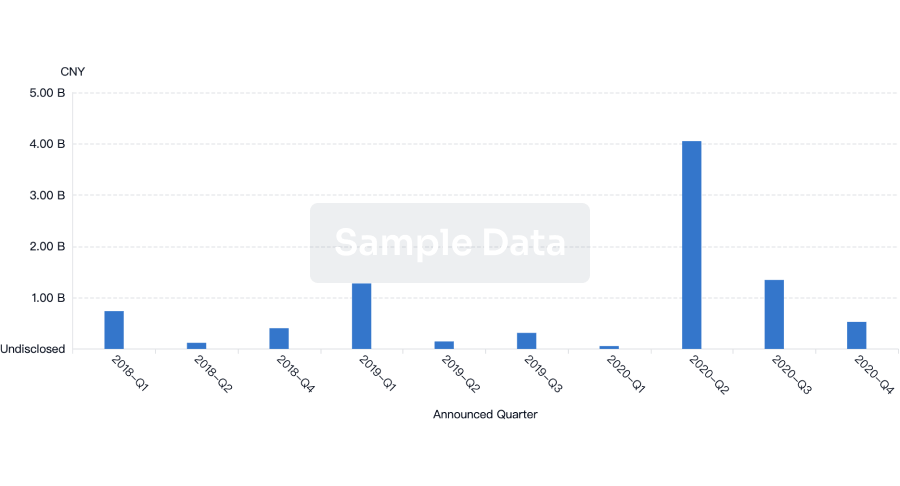

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free