Request Demo

Last update 06 Sep 2025

NL Industries, Inc.

Public Company | Subsidiary Company|1891|Texas, United States|

1,000-5,000

| NYSE: NL| Public Company | Subsidiary Company|1891|Texas, United States|

1,000-5,000

| NYSE: NL| Last update 06 Sep 2025

Overview

Related

100 Clinical Results associated with NL Industries, Inc.

Login to view more data

0 Patents (Medical) associated with NL Industries, Inc.

Login to view more data

46

Literatures (Medical) associated with NL Industries, Inc.01 Apr 1988·JPT, Journal of Petroleum Technology

Solids-Free, High-Density Brines for Packer-Fluid Applications

Author: Ezzat, A.M. ; Tillis, W.J. ; Augsburger, J.J.

Summary.:

High-density water- or oil-based muds are not stable suspensions. Laboratory corrosion data and field observations suggest that solids-free, inhibited high-density brines could be ideal packer fluids for deep, hot wells. Expensive washover and fishing operations required for recovery of tubing stuck in settled mud solid could be eliminated.

Introduction:

A worldwide review of workover operations indicated extremely high costs associated with recovery of tubing stuck in settled mud solids. High-density water- or oil-based muds are not stable suspensions when left static in a well for a long time. High temperatures and/or contamination of these muds with the produced gas and oil destroys the initial suspension properties and allows mud solids and weighting materials to settle on top of the packer and around the tubing. Expensive washover and fishing operations are then performed. During the washover, more costly complications, such as twist-off or stuck washover pipes, casing leaks, blowouts, and formation damage, could develop. When such complications occur, many wells have to be plugged and abandoned. Most of these problems could be eliminated by using solids-free packer fluids. Single-salt brines and blends of high-density brines have been tested to determine their corrosive nature. An inorganic corrosion inhibitor was developed and field tested. In the last few years, many deep, high-temperature, high-pressure wells in the Gulf of Mexico have been successfully completed with inhibited high-density brines, which were also left as packer fluids. Some of these wells were worked over, tubing and packers were retrieved easily, and no significant corrosion was observed.

Packer-Fluid Functions:

Packer fluids are placed in the casing/tubing annulus to provide a hydrostatic head necessary to control the well in case of packer failure or leaks, and to reduce the pressure differential between the inside of the tubing and the annulus, the outside of the casing and the annulus, and the perforated interval below the packer and the annulus. Packer fluids should protect tubing and casing metal surfaces from corrosion and enhance retrievability of tubing and packers.

Important Fluid Characteristics:

Packer fluids must be chemically and mechanically stable under downhole conditions; i.e., there must be no settling of suspended solids and no chemical precipitates if mixed with produced fluids or gases, Also, the fluid components must not degrade with time or temperature. Fluids must not deteriorate packer elastomers. Fluids must remain pumpable during the life of the well; i.e., no high gelation or solidification may develop over time. Fluids must not cause corrosion (inside casing or outside tubing). The fluids must not damage the producing formation because they may contact these producing zones during completion or workover operations.Water-based drilling-mud organic additives degrade upon prolonged exposure to high temperatures and sometimes generate corrosive gases, such as CO2 and H2S. Bacterial activity could also break down organic materials and/or produce corrosive elements. Lignosulfonate solutions can react electrochemically at metal surfaces to form sulfides, even at moderate temperatures. Properly formulated oil-based muds are nonconductive and should not cause corrosion. In case of packer failure or leaks, however, produced oil or gas dissolves in oil mud and destroys the suspension properties, allowing the weighting material (barite) to settle on top of the packer and to cause stuck packer and tubing.

Laboratory Testing Procedures:

Laboratory corrosion testing procedures (Appendices A and B) and equipment were developed. Data obtained explained the corrosive nature of these brines under static conditions, simulating packer-fluid applications.

Uninhibited Single-Salt Brines and High-Density-Brine Blends:

Corrosion tests were performed to determine corrosion rates for seven commercial available, single-salt, saturated brines (NaCl, KCl, KBr, NaBr, CaCl2, CaBr2, and ZnBr2) without inhibitors. Test periods were 1 to 180 days at temperatures of 250, 300, 350, and 400 degrees F [121, 149, 177, and 204 degrees C]. Initial tests were conducted on No. 1010 carbon steel coupons. An average rate for duplicate samples was calculated for each test period (Table 1). The highest corrosion rates for all brines were with the 1-day test and much lower rates were observed in longer test periods. As the temperature increased, the 1-day test corrosion rates increased significantly. For example, CaCl2 at 250 degrees F [121 degrees C) showed 5.3 mils/yr [0.135 mm/a] and at 400 degrees F [204 degrees C] showed 54.7 mils/yr [1.39 mm/a]. ZnBr2/CaBr2 at 250 degrees F [121 degrees C] showed 10.2 mils/yr [0.259 mm/a] and at 350 degrees F [177 degrees C] showed 140 mils/yr [3.56 mm/a]. These relatively high rates decreased tremendously, however, with longer exposure times of 7 and 30 days. This phenomenon indicated that the active corroding elements in the brine were being consumed and/or that the reaction produced a protective coating on the metal surface. That is, the worst corrosion reaction is during the initial contact of brines with steel, and the longer brines are left static in a well, the less corrosive they become. CaCl2/CaBr2/ZnBr2 blends with densities of 15.5, 16, 16.5, 17.5, and 18 lbm/gal [1857, 1917, 1977, 2097, and 2157 kg/m3) were tested at 250, 300, 350, and 400 degrees F [121, 149, 177, and 204 degrees C). As with the single-salt brines, the 1 day test corrosion rates were relatively higher than the 7-, 30-, and 90-day tests. These brine blends demonstrated much higher rates than the single-salt brines, especially at and above 300 degrees F [149 degrees C] (Table 2). In addition to the temperature effect on the corrosion rates, higher blend densities produced higher corrosion rates, which are attributed to the higher acidic ZnBr2 content required at the higher blend densities. Summer blends (higher crystallization temperatures) in the same density range formulated with smaller amounts of the acidic ZnBr2, showed lower corrosion rates than the winter blends (lower crystallization temperatures). In the tables and figures, LCD is last crystal to dissolve method.JPTP. 491^

01 Jan 1982·Spectrochimica acta. Part A: Molecular spectroscopy

Infrared and Raman investigation of vitreous antimony trioxide

Author: Philip J. Miller ; Charles A. Cody

IR and Raman vibrational spectra of vitreous Sb2O3 were obtained.A general valence force field calculation was performed with the assumption that the basic structural unit of the vitreous phase is O2Sb-O-SbO2.The observed and calculated spectra are in good agreement, suggesting that the glass structure of Sb2O3 is similar to that of the well known 2-dimensional layered form of vitreous As2O3.

01 Jan 1980·Advances in x-ray analysis

Analysis of Magnesium Brines by Energy Dispersive XRF

Author: Langenfeld, Debbie J. ; Reilly, John F.

An energy-dispersive x-ray fluorescence (XRF) method is described to determine Mg, S, Cl, K, and Co in concentrated Mg brines.The agreement between this method and the classical methods is satisfactory.The variation in replicate analyses is equivalent to that of other techniques.

1

News (Medical) associated with NL Industries, Inc.27 Aug 2021

Dublin, Aug. 27, 2021 (GLOBE NEWSWIRE) -- The "Titanium Additives Market Research Report by Application, by Region - Global Forecast to 2026 - Cumulative Impact of COVID-19" report has been added to ResearchAndMarkets.com's offering. The Global Titanium Additives Market size was estimated at USD 691.75 Million in 2020 and expected to reach USD 744.94 Million in 2021, at a Compound Annual Growth Rate (CAGR) 8.02% to reach USD 1,099.36 Million by 2026.Market Statistics:

The report provides market sizing and forecast across five major currencies - USD, EUR GBP, JPY, and AUD. It helps organization leaders make better decisions when currency exchange data is readily available. In this report, the years 2018 and 2019 are considered historical years, 2020 as the base year, 2021 as the estimated year, and years from 2022 to 2026 are considered the forecast period.Market Segmentation & Coverage:

This research report categorizes the Titanium Additives to forecast the revenues and analyze the trends in each of the following sub-markets:

Competitive Strategic Window:

The Competitive Strategic Window analyses the competitive landscape in terms of markets, applications, and geographies to help the vendor define an alignment or fit between their capabilities and opportunities for future growth prospects. It describes the optimal or favorable fit for the vendors to adopt successive merger and acquisition strategies, geography expansion, research & development, and new product introduction strategies to execute further business expansion and growth during a forecast period.FPNV Positioning Matrix:

The FPNV Positioning Matrix evaluates and categorizes the vendors in the Titanium Additives Market based on Business Strategy (Business Growth, Industry Coverage, Financial Viability, and Channel Support) and Product Satisfaction (Value for Money, Ease of Use, Product Features, and Customer Support) that aids businesses in better decision making and understanding the competitive landscape.Market Share Analysis:

The Market Share Analysis offers the analysis of vendors considering their contribution to the overall market. It provides the idea of its revenue generation into the overall market compared to other vendors in the space. It provides insights into how vendors are performing in terms of revenue generation and customer base compared to others. Knowing market share offers an idea of the size and competitiveness of the vendors for the base year. It reveals the market characteristics in terms of accumulation, fragmentation, dominance, and amalgamation traits.Company Usability Profiles:

The report profoundly explores the recent significant developments by the leading vendors and innovation profiles in the Global Titanium Additives Market, including Argex Titanium Inc., Arya Chem Inc., Chemours Company, CRS Holdings Inc., DuPont de Nemours, Inc., Evonik Industries AG, Farinia Group, General Electric Company, GKN Hoeganaes, GKN Sinter Metals Engineering GmbH, Honeywell International Inc, INEOS AG, Ishihara Sangyo Kaisha Ltd., Kish Company, Inc., NL Industries, Inc, Praxair International, Inc., Shandong Doguide Group Co., Ltd, SLM Solutions Group AG, SpecialChem, Tayca Corporation, Titomic Limited, Tronox Limited, UL LLC, and Venator Materials PLC.The report provides insights on the following pointers:1. Market Penetration: Provides comprehensive information on the market offered by the key players2. Market Development: Provides in-depth information about lucrative emerging markets and analyze penetration across mature segments of the markets3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developmentsThe report answers questions such as:1. What is the market size and forecast of the Global Titanium Additives Market?2. What are the inhibiting factors and impact of COVID-19 shaping the Global Titanium Additives Market during the forecast period?3. Which are the products/segments/applications/areas to invest in over the forecast period in the Global Titanium Additives Market?4. What is the competitive strategic window for opportunities in the Global Titanium Additives Market?5. What are the technology trends and regulatory frameworks in the Global Titanium Additives Market?6. What is the market share of the leading vendors in the Global Titanium Additives Market?7. What modes and strategic moves are considered suitable for entering the Global Titanium Additives Market?Key Topics Covered: 1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview4.1. Introduction4.2. Cumulative Impact of COVID-195. Market Insights5.1. Market Dynamics5.1.1. Drivers5.1.1.1. Use of titanium additives in aerospace and medical markets5.1.1.2. Growing paints and coatings industry5.1.1.3. Rising automotive production and expenditure in the construction sector5.1.1.4. Increasing demand for titanium additives for the coloring applications of food items, paper and pulp, textiles, and cosmetics5.1.2. Restraints5.1.2.1. Stringent government regulations5.1.3. Opportunities5.1.3.1. Technological innovations aimed at improving manufacturing processes5.1.3.2. Ongoing trend of using self-cleaning technologies across various industries5.1.4. Challenges5.1.4.1. Fluctuation in prices owing to a large variation in supply and demand5.2. Porters Five Forces Analysis5.2.1. Threat of New Entrants5.2.2. Threat of Substitutes5.2.3. Bargaining Power of Customers5.2.4. Bargaining Power of Suppliers5.2.5. Industry Rivalry6. Titanium Additives Market, by Application6.1. Introduction6.2. Aerospace industry6.3. Automotive Industry6.4. Engine Oil6.5. Food Industry6.6. Healthcare & Pharmaceutical6.7. Industrial Engineering7. Titanium Additives Market, by Process7.1. Introduction7.2. Direct Metal Deposition (DED)7.3. Direct Metal Laser Sintering (DMLS)7.4. Electron Beam Melting (EBM)7.5. Laser Metal Deposition (LMD)7.6. Metal Injection Molding (MIM)7.7. Selective Laser Melting (SLM)8. Americas Titanium Additives Market8.1. Introduction8.2. Argentina8.3. Brazil8.4. Canada8.5. Mexico8.6. United States9. Asia-Pacific Titanium Additives Market9.1. Introduction9.2. Australia9.3. China9.4. India9.5. Indonesia9.6. Japan9.7. Malaysia9.8. Philippines9.9. Singapore9.10. South Korea9.11. Thailand10. Europe, Middle East & Africa Titanium Additives Market10.1. Introduction10.2. France10.3. Germany10.4. Italy10.5. Netherlands10.6. Qatar10.7. Russia10.8. Saudi Arabia10.9. South Africa10.10. Spain10.11. United Arab Emirates10.12. United Kingdom11. Competitive Landscape11.1. FPNV Positioning Matrix11.1.1. Quadrants11.1.2. Business Strategy11.1.3. Product Satisfaction11.2. Market Ranking Analysis11.3. Market Share Analysis, By Key Player11.4. Competitive Scenario11.4.1. Merger & Acquisition11.4.2. Agreement, Collaboration, & Partnership11.4.3. New Product Launch & Enhancement11.4.4. Investment & Funding11.4.5. Award, Recognition, & Expansion12. Company Usability Profiles12.1. Argex Titanium Inc.12.2. Arya Chem Inc.12.3. Chemours Company12.4. CRS Holdings Inc.12.5. DuPont de Nemours, Inc.12.6. Evonik Industries AG12.7. Farinia Group12.8. General Electric Company12.9. GKN Hoeganaes12.10. GKN Sinter Metals Engineering GmbH12.11. Honeywell International Inc12.12. INEOS AG12.13. Ishihara Sangyo Kaisha Ltd.12.14. Kish Company, Inc.12.15. NL Industries, Inc12.16. Praxair International, Inc.12.17. Shandong Doguide Group Co., Ltd12.18. SLM Solutions Group AG12.19. SpecialChem12.20. Tayca Corporation12.21. Titomic Limited12.22. Tronox Limited12.23. UL LLC12.24. Venator Materials PLC13. Appendix

For more information about this report visit

Acquisition

100 Deals associated with NL Industries, Inc.

Login to view more data

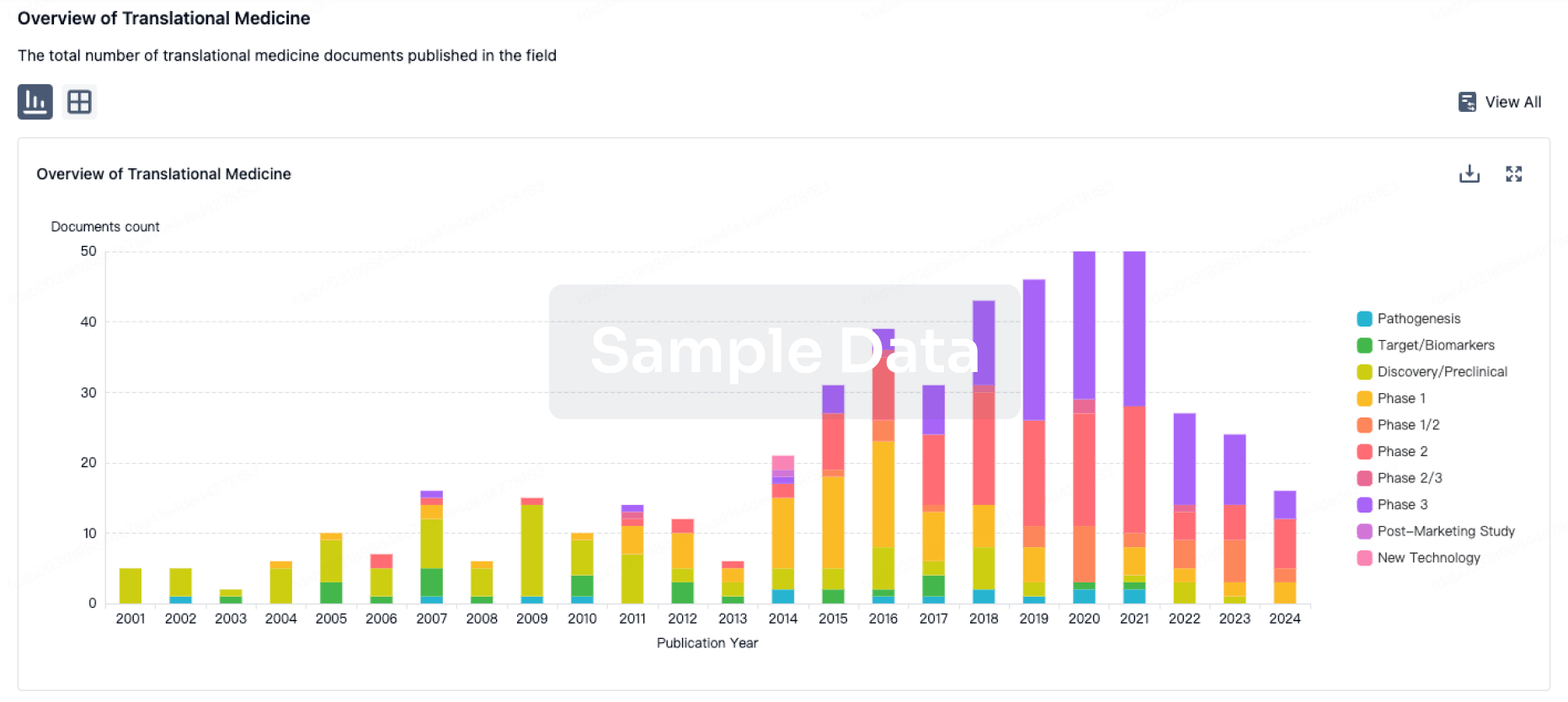

100 Translational Medicine associated with NL Industries, Inc.

Login to view more data

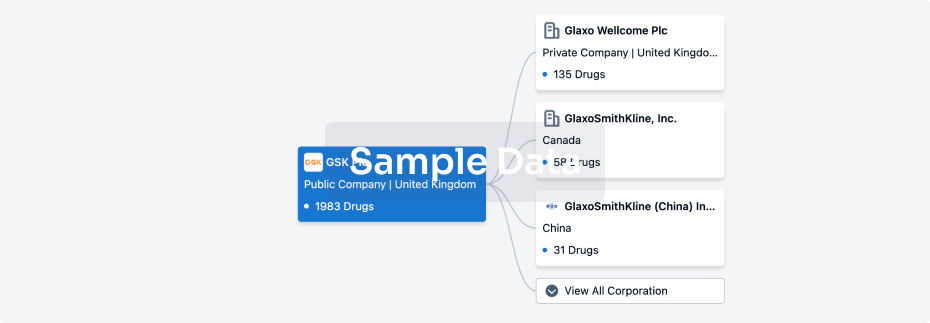

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 18 Dec 2025

No data posted

Login to keep update

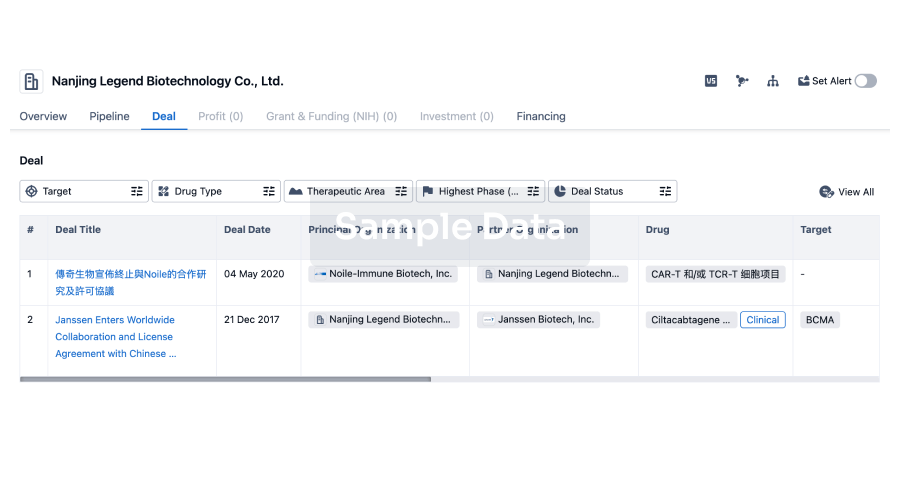

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

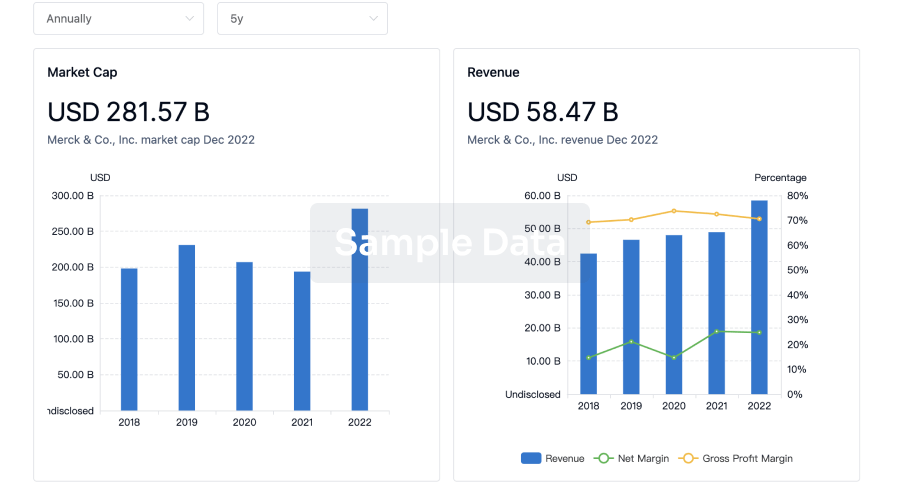

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

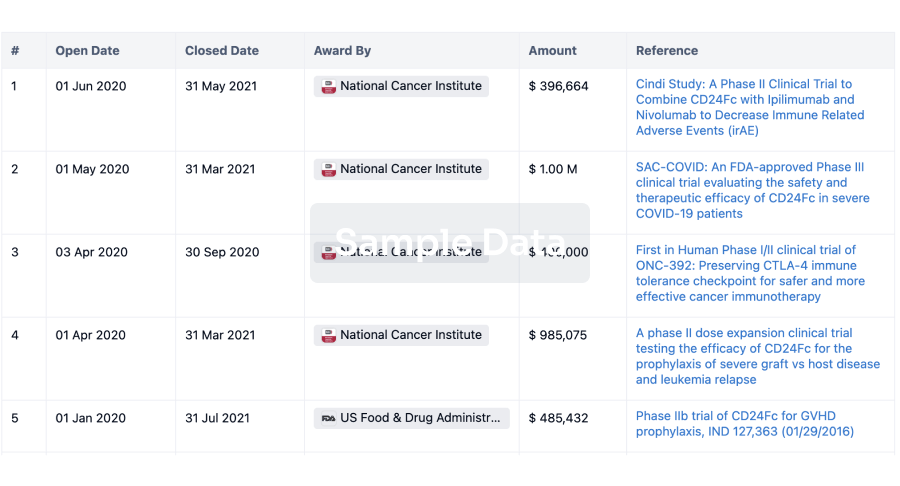

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

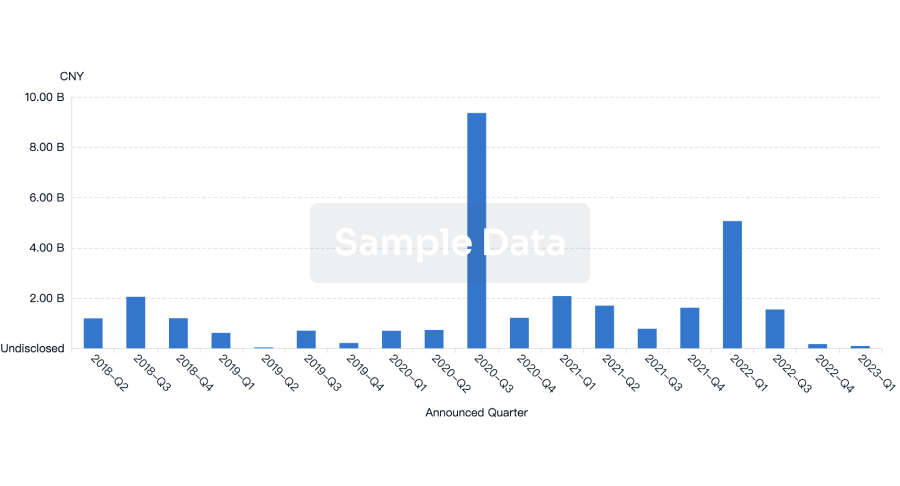

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

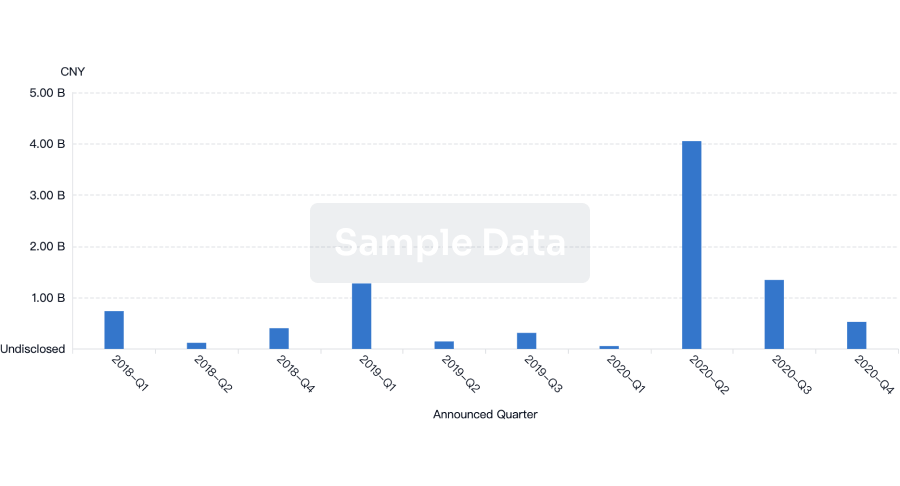

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free