Request Demo

What is the mechanism of Hypromellose?

18 July 2024

Hypromellose, also known as hydroxypropyl methylcellulose (HPMC), is a widely used polymer in pharmaceutical formulations, ophthalmic solutions, and various industrial applications. Its versatility stems from its unique properties and the mechanisms by which it operates. Understanding the mechanism of hypromellose can provide insights into how it functions as a binder, film former, and viscosity enhancer.

At its core, hypromellose is a cellulose derivative. It is produced by the partial methylation and hydroxypropylation of cellulose, which is the primary structural component of plant cell walls. This chemical modification confers hypromellose with distinct physicochemical properties, enabling it to perform a variety of roles.

One of the primary mechanisms by which hypromellose operates is through its ability to form gels and viscous solutions when dispersed in water. This occurs due to its hydrophilic nature, which allows it to absorb water and swell. When hypromellose is added to an aqueous solution, it undergoes a hydration process where water molecules penetrate the polymer chains, causing them to expand. This results in an increase in the viscosity of the solution, which can be tailored by adjusting the concentration of hypromellose.

In pharmaceutical applications, hypromellose is frequently used as a binder in tablet formulations. Its binding mechanism involves the formation of a cohesive matrix that holds the tablet's ingredients together. During the tablet compression process, hypromellose particles deform and interlock, creating a strong bond between the active pharmaceutical ingredient (API) and other excipients. This ensures that the tablet remains intact during handling and storage but disintegrates appropriately upon ingestion.

Hypromellose also acts as a film former in coatings for tablets and capsules. The mechanism here involves the formation of a continuous film when hypromellose is dissolved in a suitable solvent and applied to the surface of the dosage form. As the solvent evaporates, hypromellose molecules align and coalesce to create a uniform film. This film can serve various functions, such as protecting the API from environmental factors, masking unpleasant tastes, and controlling the release of the drug.

In ophthalmic solutions, hypromellose is utilized as a lubricant and viscosity enhancer. Its mechanism of action involves forming a protective and lubricating layer over the ocular surface, which helps to alleviate dryness and irritation. When applied as eye drops, hypromellose increases the retention time of the solution on the eye, providing prolonged relief and improving comfort for the user.

The versatility of hypromellose is further highlighted by its use in controlled-release drug delivery systems. In these systems, hypromellose can form a gel barrier that modulates the release rate of the drug. Upon contact with gastrointestinal fluids, the outer layer of a hypromellose-based tablet swells and forms a gel-like layer. This layer controls the diffusion of the drug from the tablet core to the surrounding environment, thereby providing a sustained release profile. The rate of drug release can be fine-tuned by varying the molecular weight and concentration of hypromellose in the formulation.

In summary, hypromellose operates through mechanisms of hydration, gel formation, film formation, and matrix formation. Its ability to absorb water, increase viscosity, form cohesive matrices, and create protective films makes it an invaluable excipient in pharmaceutical formulations and beyond. By understanding these mechanisms, formulators can effectively leverage hypromellose to develop innovative and effective products.

At its core, hypromellose is a cellulose derivative. It is produced by the partial methylation and hydroxypropylation of cellulose, which is the primary structural component of plant cell walls. This chemical modification confers hypromellose with distinct physicochemical properties, enabling it to perform a variety of roles.

One of the primary mechanisms by which hypromellose operates is through its ability to form gels and viscous solutions when dispersed in water. This occurs due to its hydrophilic nature, which allows it to absorb water and swell. When hypromellose is added to an aqueous solution, it undergoes a hydration process where water molecules penetrate the polymer chains, causing them to expand. This results in an increase in the viscosity of the solution, which can be tailored by adjusting the concentration of hypromellose.

In pharmaceutical applications, hypromellose is frequently used as a binder in tablet formulations. Its binding mechanism involves the formation of a cohesive matrix that holds the tablet's ingredients together. During the tablet compression process, hypromellose particles deform and interlock, creating a strong bond between the active pharmaceutical ingredient (API) and other excipients. This ensures that the tablet remains intact during handling and storage but disintegrates appropriately upon ingestion.

Hypromellose also acts as a film former in coatings for tablets and capsules. The mechanism here involves the formation of a continuous film when hypromellose is dissolved in a suitable solvent and applied to the surface of the dosage form. As the solvent evaporates, hypromellose molecules align and coalesce to create a uniform film. This film can serve various functions, such as protecting the API from environmental factors, masking unpleasant tastes, and controlling the release of the drug.

In ophthalmic solutions, hypromellose is utilized as a lubricant and viscosity enhancer. Its mechanism of action involves forming a protective and lubricating layer over the ocular surface, which helps to alleviate dryness and irritation. When applied as eye drops, hypromellose increases the retention time of the solution on the eye, providing prolonged relief and improving comfort for the user.

The versatility of hypromellose is further highlighted by its use in controlled-release drug delivery systems. In these systems, hypromellose can form a gel barrier that modulates the release rate of the drug. Upon contact with gastrointestinal fluids, the outer layer of a hypromellose-based tablet swells and forms a gel-like layer. This layer controls the diffusion of the drug from the tablet core to the surrounding environment, thereby providing a sustained release profile. The rate of drug release can be fine-tuned by varying the molecular weight and concentration of hypromellose in the formulation.

In summary, hypromellose operates through mechanisms of hydration, gel formation, film formation, and matrix formation. Its ability to absorb water, increase viscosity, form cohesive matrices, and create protective films makes it an invaluable excipient in pharmaceutical formulations and beyond. By understanding these mechanisms, formulators can effectively leverage hypromellose to develop innovative and effective products.

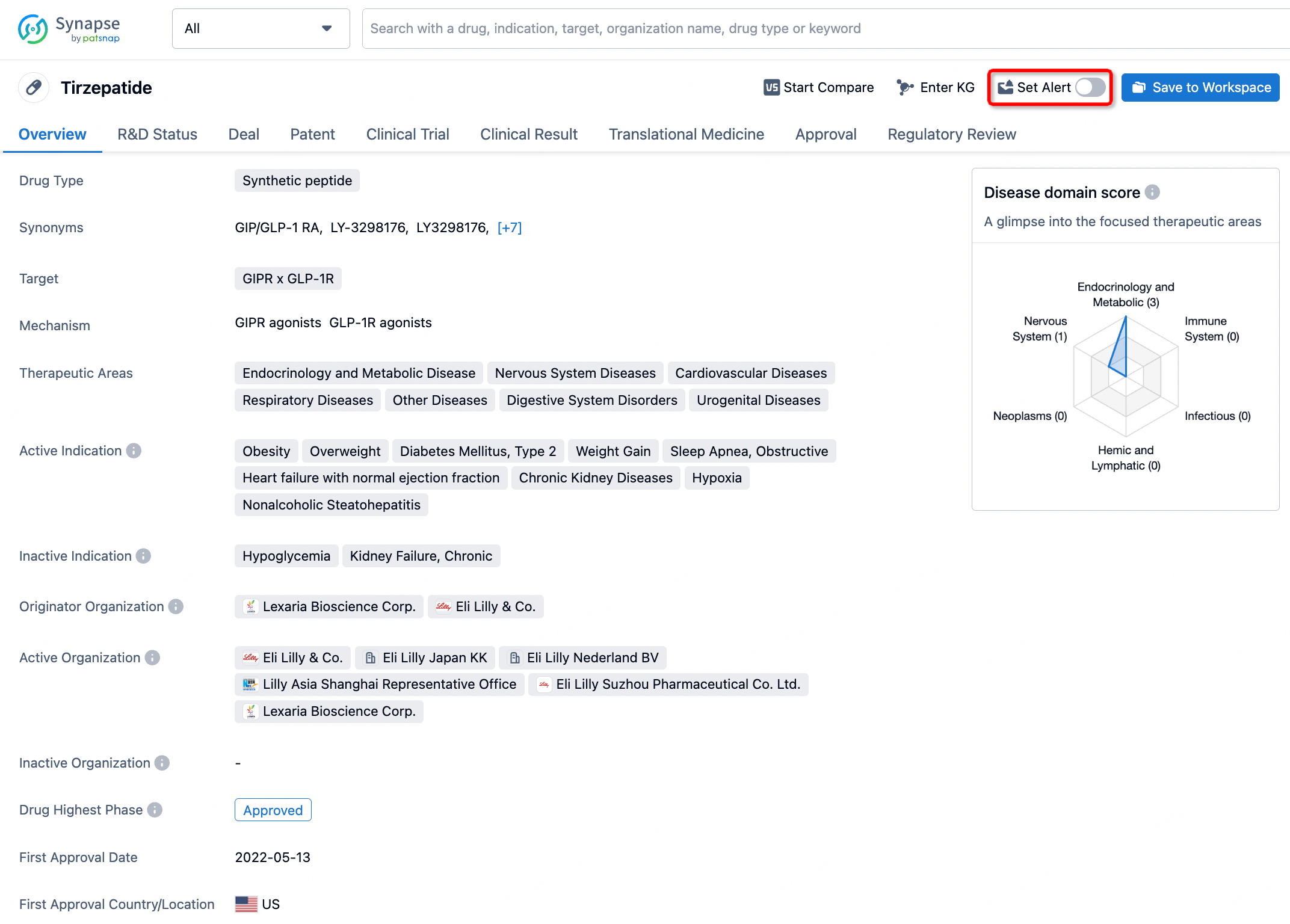

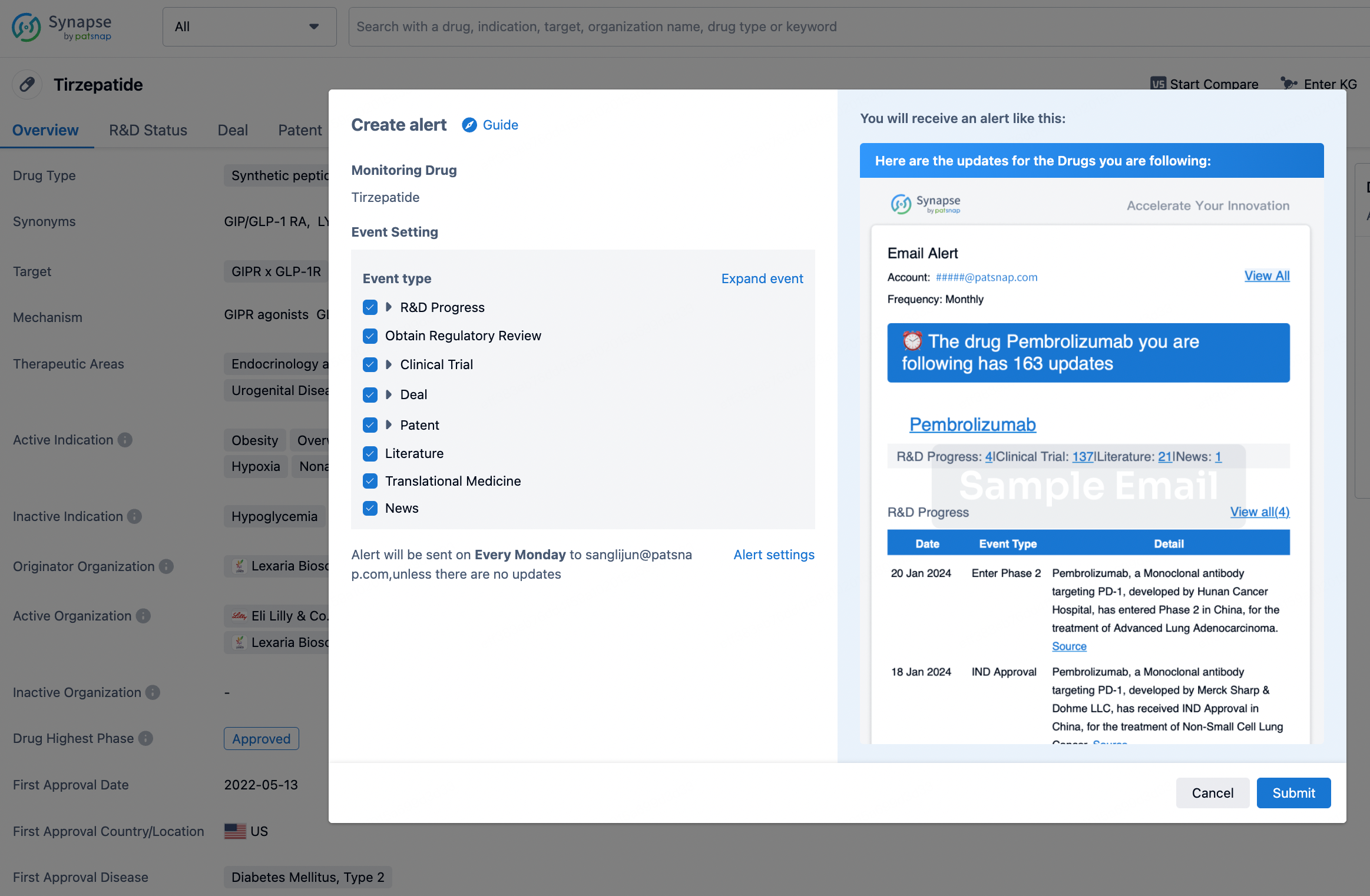

How to obtain the latest development progress of all drugs?

In the Synapse database, you can stay updated on the latest research and development advances of all drugs. This service is accessible anytime and anywhere, with updates available daily or weekly. Use the "Set Alert" function to stay informed. Click on the image below to embark on a brand new journey of drug discovery!

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.