Request Demo

What is the mechanism of Sodium Alginate?

17 July 2024

Sodium alginate is a fascinating natural polysaccharide derived from the cell walls of brown seaweed. It has gained significant attention in various industries, including food, pharmaceutical, and biomedical fields, due to its unique properties and versatile applications. To fully appreciate its potential, it is essential to understand the mechanism of sodium alginate.

At its core, sodium alginate is composed of linear chains of α-L-guluronate (G) and β-D-mannuronate (M) residues arranged in blocks. This composition enables the formation of a gel-like substance when in contact with divalent cations like calcium ions (Ca²⁺). The gelation process is central to sodium alginate's functionality and applications.

When dissolved in water, sodium alginate forms a viscous solution. This is due to the sodium ions (Na⁺) maintaining the polysaccharide chains in a dispersed state. However, upon the introduction of divalent cations, particularly calcium ions, a noticeable transformation occurs. The calcium ions preferentially bind to the G-blocks of the alginate chains, displacing the sodium ions. This binding process creates ionic cross-links between the chains, resulting in the formation of an "egg-box" structure. The egg-box model describes how the calcium ions bridge the G-blocks, effectively locking the chains together and forming a three-dimensional network.

This gelation mechanism is highly dependent on the concentration and type of divalent cations present. Lower concentrations might only partially cross-link the alginate, resulting in a softer gel, while higher concentrations can produce a more rigid and robust gel. The proportion of G and M blocks in the alginate also influences the gel's properties. Alginates with a higher G-block content tend to form stronger, more brittle gels, whereas those with more M-blocks yield softer, more elastic gels.

In the food industry, sodium alginate’s gelation properties are utilized for thickening, gelling, and stabilizing purposes. It is commonly found in products like ice cream, sauces, and dressings, where it helps to create a desirable texture and consistency. Additionally, it is used in the production of edible films and coatings, which can enhance the shelf life and quality of food products.

In the pharmaceutical and biomedical sectors, the ability of sodium alginate to form hydrogels in the presence of calcium ions is harnessed for drug delivery systems and tissue engineering applications. For instance, alginate beads can encapsulate drugs, providing a controlled release mechanism. The biocompatibility and non-toxicity of sodium alginate make it an attractive option for wound dressings and scaffolds for tissue regeneration.

Moreover, sodium alginate's gelation mechanism is exploited in the encapsulation of cells for various biotechnological applications. The mild gelation conditions ensure that encapsulated cells remain viable, making alginate an ideal matrix for cell immobilization and culture. This is particularly beneficial for the development of artificial organs and bioartificial tissues.

In conclusion, the mechanism of sodium alginate revolves around its ability to form gels through ionic cross-linking with divalent cations, particularly calcium ions. This unique property is the cornerstone of its wide-ranging applications in food, pharmaceutical, and biomedical industries. Understanding the nuances of this gelation process allows for the optimization of sodium alginate's functionality in various products and technologies, highlighting its indispensable role in modern science and industry.

At its core, sodium alginate is composed of linear chains of α-L-guluronate (G) and β-D-mannuronate (M) residues arranged in blocks. This composition enables the formation of a gel-like substance when in contact with divalent cations like calcium ions (Ca²⁺). The gelation process is central to sodium alginate's functionality and applications.

When dissolved in water, sodium alginate forms a viscous solution. This is due to the sodium ions (Na⁺) maintaining the polysaccharide chains in a dispersed state. However, upon the introduction of divalent cations, particularly calcium ions, a noticeable transformation occurs. The calcium ions preferentially bind to the G-blocks of the alginate chains, displacing the sodium ions. This binding process creates ionic cross-links between the chains, resulting in the formation of an "egg-box" structure. The egg-box model describes how the calcium ions bridge the G-blocks, effectively locking the chains together and forming a three-dimensional network.

This gelation mechanism is highly dependent on the concentration and type of divalent cations present. Lower concentrations might only partially cross-link the alginate, resulting in a softer gel, while higher concentrations can produce a more rigid and robust gel. The proportion of G and M blocks in the alginate also influences the gel's properties. Alginates with a higher G-block content tend to form stronger, more brittle gels, whereas those with more M-blocks yield softer, more elastic gels.

In the food industry, sodium alginate’s gelation properties are utilized for thickening, gelling, and stabilizing purposes. It is commonly found in products like ice cream, sauces, and dressings, where it helps to create a desirable texture and consistency. Additionally, it is used in the production of edible films and coatings, which can enhance the shelf life and quality of food products.

In the pharmaceutical and biomedical sectors, the ability of sodium alginate to form hydrogels in the presence of calcium ions is harnessed for drug delivery systems and tissue engineering applications. For instance, alginate beads can encapsulate drugs, providing a controlled release mechanism. The biocompatibility and non-toxicity of sodium alginate make it an attractive option for wound dressings and scaffolds for tissue regeneration.

Moreover, sodium alginate's gelation mechanism is exploited in the encapsulation of cells for various biotechnological applications. The mild gelation conditions ensure that encapsulated cells remain viable, making alginate an ideal matrix for cell immobilization and culture. This is particularly beneficial for the development of artificial organs and bioartificial tissues.

In conclusion, the mechanism of sodium alginate revolves around its ability to form gels through ionic cross-linking with divalent cations, particularly calcium ions. This unique property is the cornerstone of its wide-ranging applications in food, pharmaceutical, and biomedical industries. Understanding the nuances of this gelation process allows for the optimization of sodium alginate's functionality in various products and technologies, highlighting its indispensable role in modern science and industry.

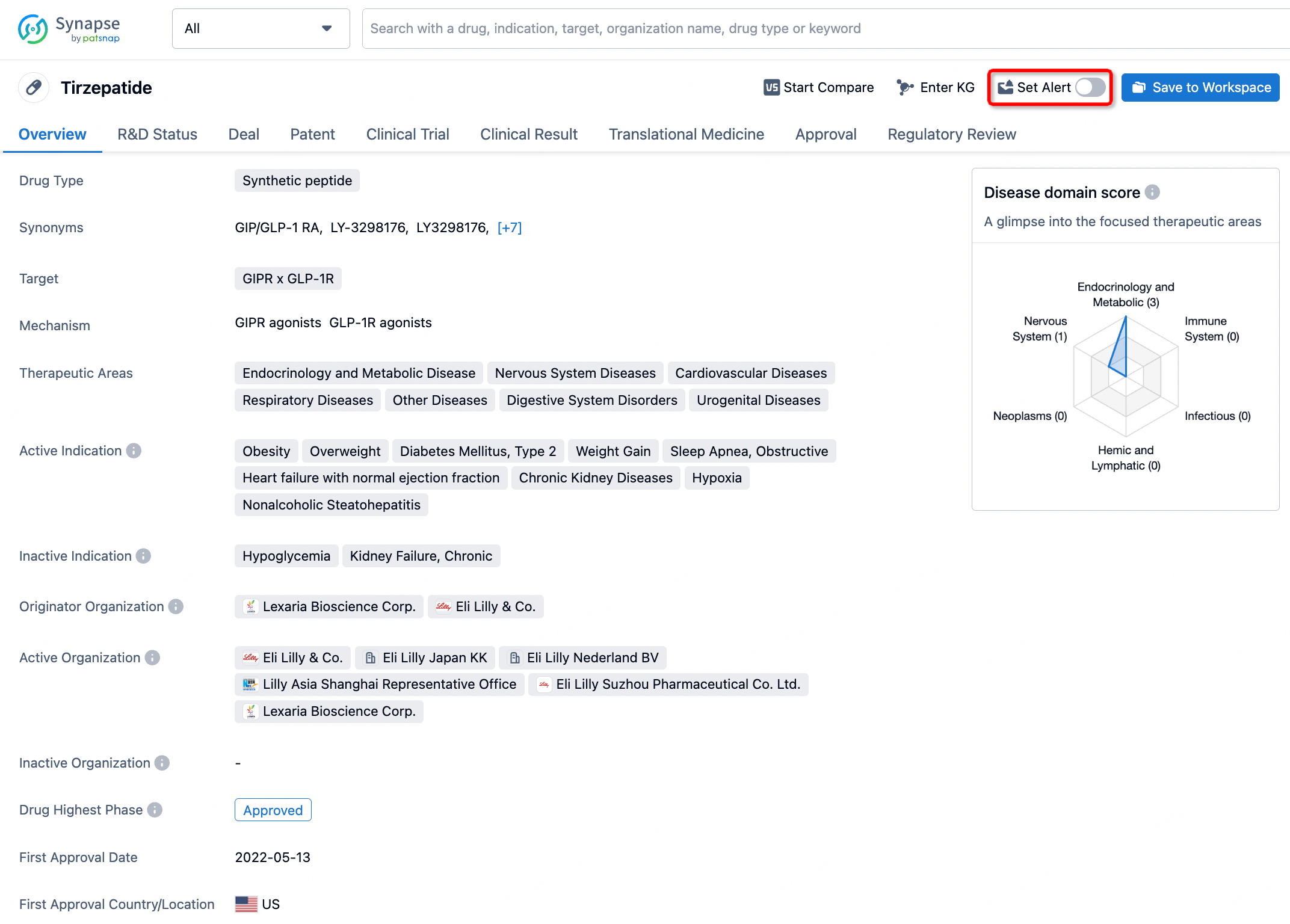

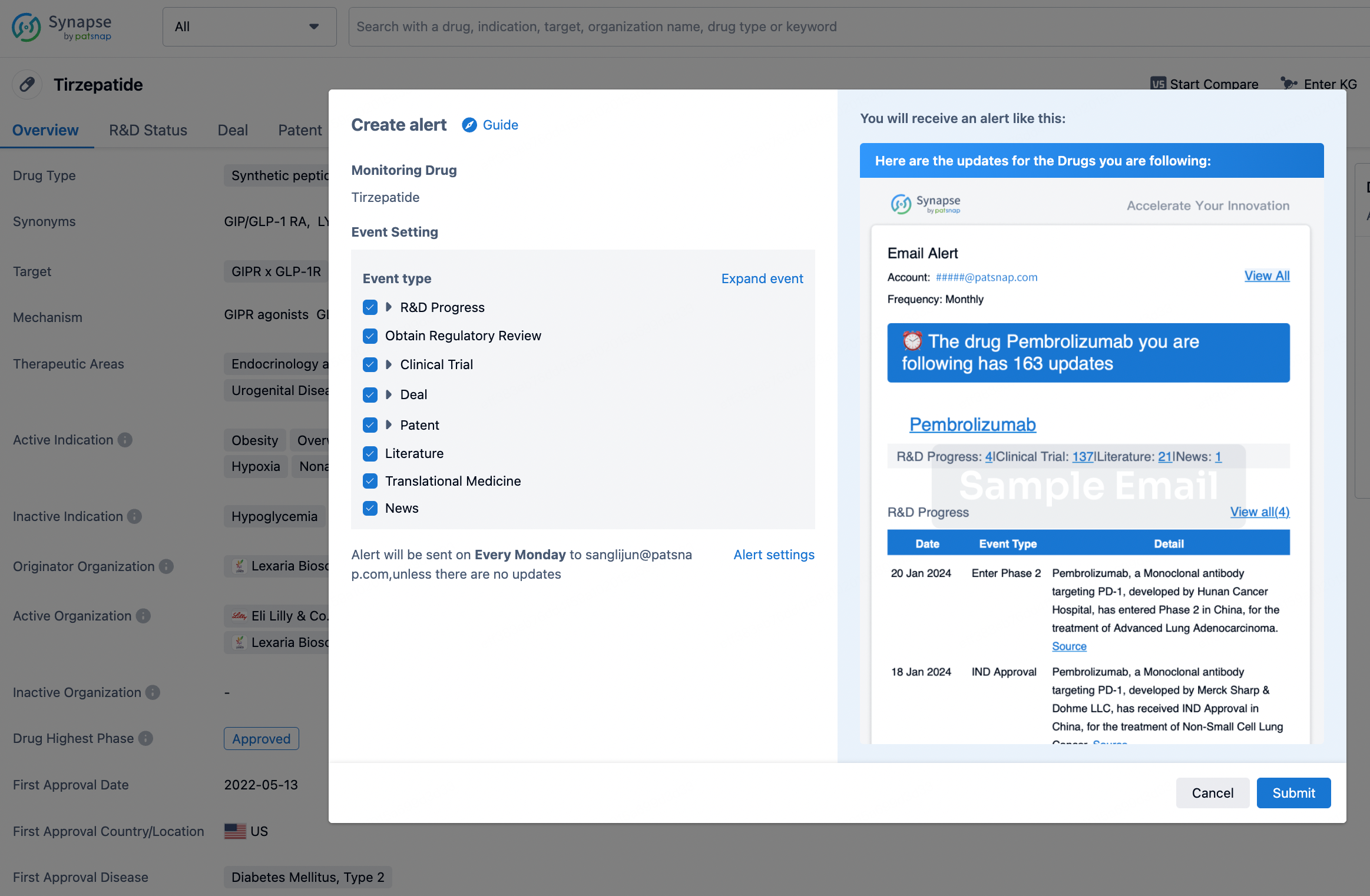

How to obtain the latest development progress of all drugs?

In the Synapse database, you can stay updated on the latest research and development advances of all drugs. This service is accessible anytime and anywhere, with updates available daily or weekly. Use the "Set Alert" function to stay informed. Click on the image below to embark on a brand new journey of drug discovery!

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.