Request Demo

What is the mechanism of Spherical adsorption charcoal?

17 July 2024

Spherical adsorption charcoal, also known as spherical activated carbon, is a porous material widely used in various industries for its remarkable adsorptive properties. The process of adsorption involves the adherence of atoms, ions, or molecules from a gas, liquid, or dissolved solid to a surface. This phenomenon occurs at the interface of the solid-phase material and the fluid phase, forming a molecular or atomic film. Here, we will delve into the intricacies of the mechanism by which spherical adsorption charcoal functions.

The structure of spherical adsorption charcoal is a critical factor contributing to its superior adsorption capabilities. Unlike traditional granular or powdered activated carbon, spherical adsorption charcoal is manufactured to form uniform spherical particles. This unique geometry offers several advantages, including enhanced mechanical strength, lower dust production, and improved packing density in adsorption columns. The uniform shape and size of these spheres lead to consistent flow characteristics and reduce the pressure drop during the adsorption process.

At the heart of the adsorption mechanism is the development of an extensive network of micropores and mesopores within the carbon spheres. These pores significantly increase the surface area available for adsorption. During the production of spherical activated carbon, raw materials such as coconut shells, wood, or coal are subjected to processes like carbonization and activation. Carbonization involves heating the raw material in the absence of air to remove volatile components, while activation enhances the porosity and surface area of the carbon. Chemical activation using agents like phosphoric acid or physical activation using gases like steam are common methods to achieve the desired pore structure.

When an adsorbate comes into contact with spherical adsorption charcoal, several forces drive the adsorption process. Van der Waals forces, electrostatic forces, and chemical interactions play a crucial role in attracting and holding the adsorbate molecules onto the carbon surface. The large surface area provided by the porous structure maximizes these interactions, enabling the charcoal to capture a significant amount of adsorbates.

The adsorption process can be categorized into two primary types: physisorption and chemisorption. Physisorption is characterized by relatively weak van der Waals forces and is reversible, meaning the adsorbate can be desorbed from the surface without altering the adsorbent's structure. This type of adsorption is typically used for applications like air purification, where volatile organic compounds or pollutants are removed from the air.

Chemisorption, on the other hand, involves the formation of stronger chemical bonds between the adsorbate and the adsorbent. This type of adsorption is generally irreversible and is employed in applications requiring the removal of specific contaminants, such as heavy metals from water. Chemisorption often results in changes to the adsorbent's surface, which might necessitate regeneration or replacement of the spherical adsorption charcoal.

In addition to the inherent properties of spherical activated carbon, external factors such as temperature, pressure, and concentration of the adsorbate also influence the adsorption efficiency. Higher temperatures can increase the kinetic energy of adsorbate molecules, leading to a higher rate of adsorption. However, excessively high temperatures might desorb the adsorbed molecules, reducing the overall effectiveness. Similarly, higher pressure can push more adsorbate molecules into the pores of the carbon, enhancing the adsorption capacity. The concentration gradient between the adsorbate in the fluid phase and the concentration on the surface of the carbon also drives the adsorption process; higher initial concentrations typically result in greater adsorption until equilibrium is reached.

Spherical adsorption charcoal finds applications in a myriad of fields, including water treatment, air purification, chemical recovery, and medical applications. In water treatment, it effectively removes organic contaminants, chlorine, and heavy metals, ensuring safe drinking water. In air purification systems, it captures volatile organic compounds, odors, and harmful gases, improving indoor air quality. In industrial processes, it aids in the recovery of valuable chemicals and the purification of gases. Medical applications include its use in drug delivery systems and as an adsorbent in hemoperfusion devices for the removal of toxins from blood.

In conclusion, the mechanism of spherical adsorption charcoal hinges on its unique structure, extensive porosity, and the interplay of physical and chemical forces driving the adsorption process. Its versatile applications across diverse fields underscore its significance as a vital material for addressing environmental and industrial challenges. Through continued research and development, the efficiency and scope of spherical adsorption charcoal are likely to expand, offering even more robust solutions for future needs.

The structure of spherical adsorption charcoal is a critical factor contributing to its superior adsorption capabilities. Unlike traditional granular or powdered activated carbon, spherical adsorption charcoal is manufactured to form uniform spherical particles. This unique geometry offers several advantages, including enhanced mechanical strength, lower dust production, and improved packing density in adsorption columns. The uniform shape and size of these spheres lead to consistent flow characteristics and reduce the pressure drop during the adsorption process.

At the heart of the adsorption mechanism is the development of an extensive network of micropores and mesopores within the carbon spheres. These pores significantly increase the surface area available for adsorption. During the production of spherical activated carbon, raw materials such as coconut shells, wood, or coal are subjected to processes like carbonization and activation. Carbonization involves heating the raw material in the absence of air to remove volatile components, while activation enhances the porosity and surface area of the carbon. Chemical activation using agents like phosphoric acid or physical activation using gases like steam are common methods to achieve the desired pore structure.

When an adsorbate comes into contact with spherical adsorption charcoal, several forces drive the adsorption process. Van der Waals forces, electrostatic forces, and chemical interactions play a crucial role in attracting and holding the adsorbate molecules onto the carbon surface. The large surface area provided by the porous structure maximizes these interactions, enabling the charcoal to capture a significant amount of adsorbates.

The adsorption process can be categorized into two primary types: physisorption and chemisorption. Physisorption is characterized by relatively weak van der Waals forces and is reversible, meaning the adsorbate can be desorbed from the surface without altering the adsorbent's structure. This type of adsorption is typically used for applications like air purification, where volatile organic compounds or pollutants are removed from the air.

Chemisorption, on the other hand, involves the formation of stronger chemical bonds between the adsorbate and the adsorbent. This type of adsorption is generally irreversible and is employed in applications requiring the removal of specific contaminants, such as heavy metals from water. Chemisorption often results in changes to the adsorbent's surface, which might necessitate regeneration or replacement of the spherical adsorption charcoal.

In addition to the inherent properties of spherical activated carbon, external factors such as temperature, pressure, and concentration of the adsorbate also influence the adsorption efficiency. Higher temperatures can increase the kinetic energy of adsorbate molecules, leading to a higher rate of adsorption. However, excessively high temperatures might desorb the adsorbed molecules, reducing the overall effectiveness. Similarly, higher pressure can push more adsorbate molecules into the pores of the carbon, enhancing the adsorption capacity. The concentration gradient between the adsorbate in the fluid phase and the concentration on the surface of the carbon also drives the adsorption process; higher initial concentrations typically result in greater adsorption until equilibrium is reached.

Spherical adsorption charcoal finds applications in a myriad of fields, including water treatment, air purification, chemical recovery, and medical applications. In water treatment, it effectively removes organic contaminants, chlorine, and heavy metals, ensuring safe drinking water. In air purification systems, it captures volatile organic compounds, odors, and harmful gases, improving indoor air quality. In industrial processes, it aids in the recovery of valuable chemicals and the purification of gases. Medical applications include its use in drug delivery systems and as an adsorbent in hemoperfusion devices for the removal of toxins from blood.

In conclusion, the mechanism of spherical adsorption charcoal hinges on its unique structure, extensive porosity, and the interplay of physical and chemical forces driving the adsorption process. Its versatile applications across diverse fields underscore its significance as a vital material for addressing environmental and industrial challenges. Through continued research and development, the efficiency and scope of spherical adsorption charcoal are likely to expand, offering even more robust solutions for future needs.

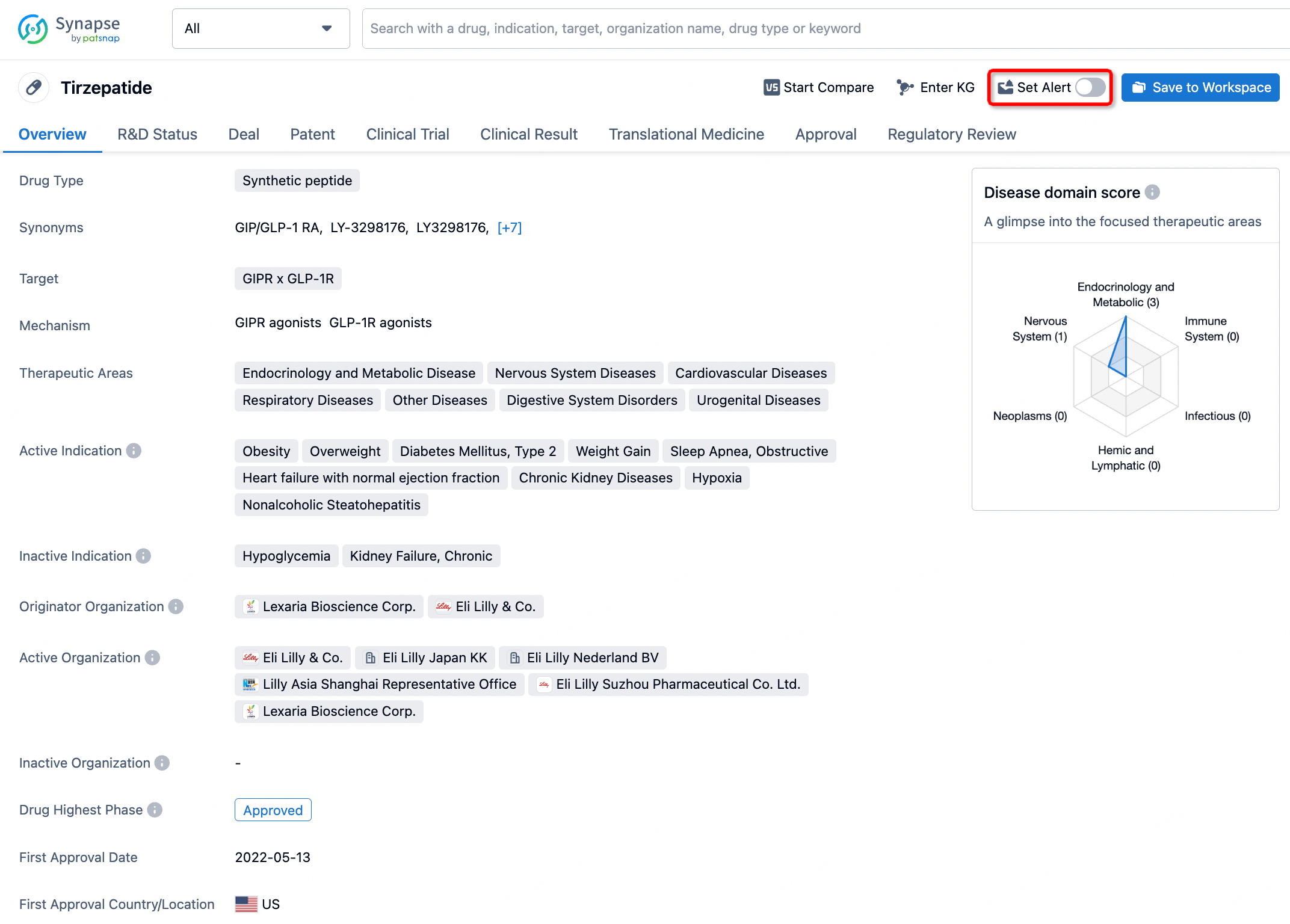

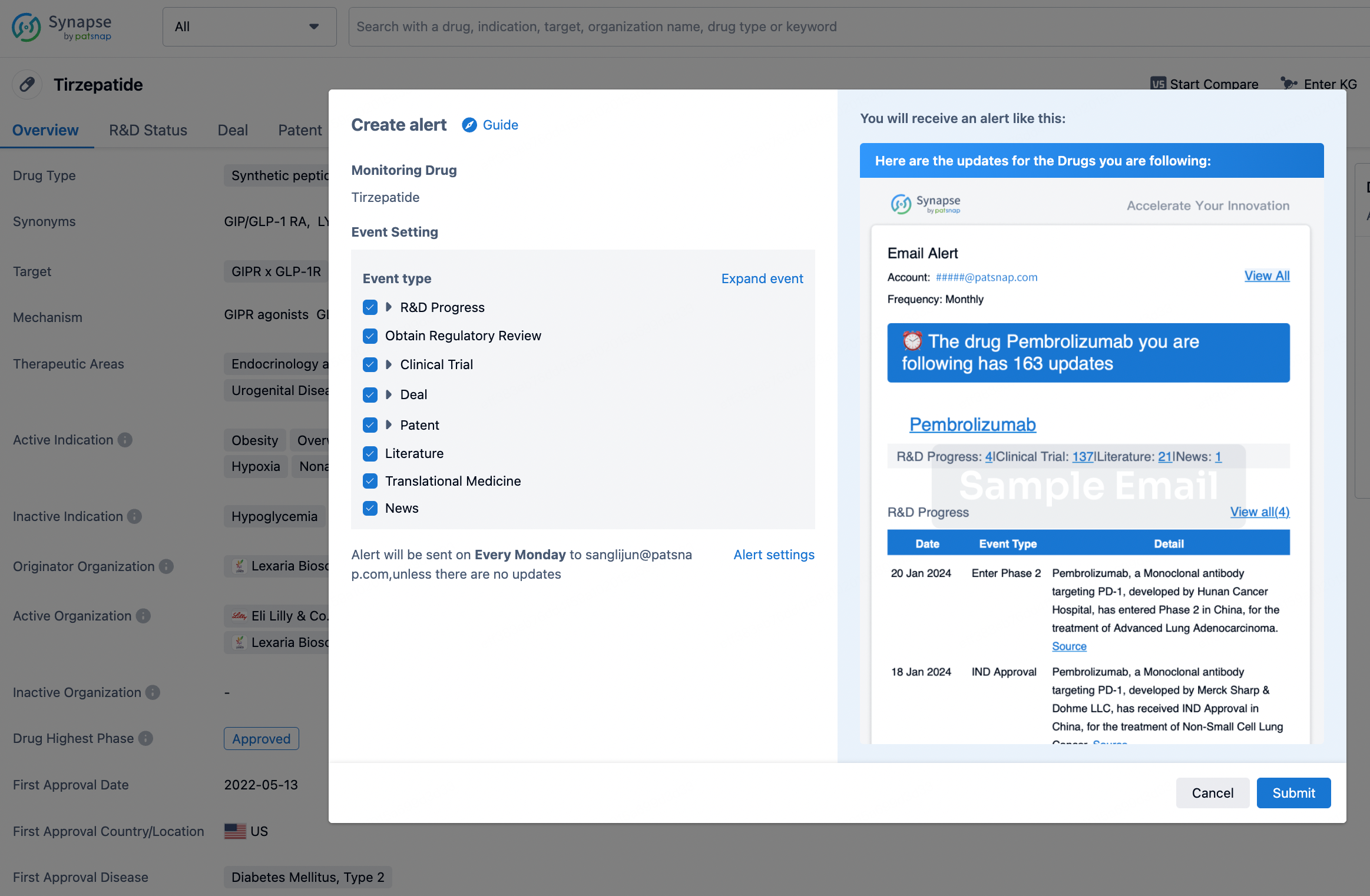

How to obtain the latest development progress of all drugs?

In the Synapse database, you can stay updated on the latest research and development advances of all drugs. This service is accessible anytime and anywhere, with updates available daily or weekly. Use the "Set Alert" function to stay informed. Click on the image below to embark on a brand new journey of drug discovery!

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.