Request Demo

What is the mechanism of TALC?

17 July 2024

Talc, a mineral composed primarily of magnesium, silicon, and oxygen, is known for its softness and versatility. It has a wide range of applications, including in cosmetics, pharmaceuticals, and the ceramics industry. The mechanism of talc involves understanding its properties, formation, and behavior in different environments.

Talc's structure is characterized by its layered, sheet-like form. Each layer consists of a trioctahedral combination of magnesium and hydroxide ions, sandwiched between two layers of tetrahedral silicon-oxygen units. The layers are held together by weak van der Waals forces, which accounts for talc's slippery feel and excellent lubricating properties. This unique structure is what makes talc so versatile in various applications.

The formation of talc typically occurs through the metamorphosis of magnesium-rich rocks, such as serpentine, in the presence of carbon dioxide and water. This process, known as talc carbonation, involves a series of complex chemical reactions. First, carbonation of the magnesium silicate minerals occurs, producing magnesium carbonate and silica. Over time, further reaction with available silica and magnesium ions forms the characteristic talc sheets. This metamorphic process can take place over long geological time periods, often in regions with high pressure and temperature conditions.

In terms of its functionality, talc's hydrophobic nature makes it an excellent moisture barrier, which is why it's commonly used in cosmetics and personal care products like baby powder and body powders. It helps to absorb excess moisture, reduce friction, and prevent rashes. In pharmaceuticals, talc serves as a filler and a lubricant in tablet manufacturing, ensuring that the pills do not stick to the equipment and that they have a smooth, uniform appearance.

Talc's thermal stability and resistance to chemical attacks also make it valuable in the ceramics and paint industries. In ceramics, it is used to improve the strength and durability of the final product by acting as a flux, lowering the melting temperature of the mix. In the paint industry, talc enhances the paint’s ability to adhere to surfaces, improves its brightness and whiteness, and provides a smooth, matte finish.

Another significant application of talc is in the plastics industry. Talc is added to polypropylene and other plastic compounds to improve their mechanical properties, such as stiffness, tensile strength, and resistance to heat. It also aids in the production process by improving the flow characteristics of the molten plastic, making it easier to mold and shape.

Talc's impact on human health and the environment has been a topic of concern and controversy. Inhalation of talc dust can cause respiratory issues, and there have been debates over the potential link between talc use in the genital area and ovarian cancer. Regulatory bodies like the FDA and EPA continue to study talc's safety and enforce strict guidelines to ensure consumer safety.

In conclusion, the mechanism of talc involves understanding its unique structural properties, its formation through geological processes, and its wide range of applications across various industries. Talc's versatility is due to its softness, hydrophobicity, chemical inertness, and thermal stability, making it an indispensable material in many everyday products. However, ongoing research and regulation are essential to address health and safety concerns associated with its use.

Talc's structure is characterized by its layered, sheet-like form. Each layer consists of a trioctahedral combination of magnesium and hydroxide ions, sandwiched between two layers of tetrahedral silicon-oxygen units. The layers are held together by weak van der Waals forces, which accounts for talc's slippery feel and excellent lubricating properties. This unique structure is what makes talc so versatile in various applications.

The formation of talc typically occurs through the metamorphosis of magnesium-rich rocks, such as serpentine, in the presence of carbon dioxide and water. This process, known as talc carbonation, involves a series of complex chemical reactions. First, carbonation of the magnesium silicate minerals occurs, producing magnesium carbonate and silica. Over time, further reaction with available silica and magnesium ions forms the characteristic talc sheets. This metamorphic process can take place over long geological time periods, often in regions with high pressure and temperature conditions.

In terms of its functionality, talc's hydrophobic nature makes it an excellent moisture barrier, which is why it's commonly used in cosmetics and personal care products like baby powder and body powders. It helps to absorb excess moisture, reduce friction, and prevent rashes. In pharmaceuticals, talc serves as a filler and a lubricant in tablet manufacturing, ensuring that the pills do not stick to the equipment and that they have a smooth, uniform appearance.

Talc's thermal stability and resistance to chemical attacks also make it valuable in the ceramics and paint industries. In ceramics, it is used to improve the strength and durability of the final product by acting as a flux, lowering the melting temperature of the mix. In the paint industry, talc enhances the paint’s ability to adhere to surfaces, improves its brightness and whiteness, and provides a smooth, matte finish.

Another significant application of talc is in the plastics industry. Talc is added to polypropylene and other plastic compounds to improve their mechanical properties, such as stiffness, tensile strength, and resistance to heat. It also aids in the production process by improving the flow characteristics of the molten plastic, making it easier to mold and shape.

Talc's impact on human health and the environment has been a topic of concern and controversy. Inhalation of talc dust can cause respiratory issues, and there have been debates over the potential link between talc use in the genital area and ovarian cancer. Regulatory bodies like the FDA and EPA continue to study talc's safety and enforce strict guidelines to ensure consumer safety.

In conclusion, the mechanism of talc involves understanding its unique structural properties, its formation through geological processes, and its wide range of applications across various industries. Talc's versatility is due to its softness, hydrophobicity, chemical inertness, and thermal stability, making it an indispensable material in many everyday products. However, ongoing research and regulation are essential to address health and safety concerns associated with its use.

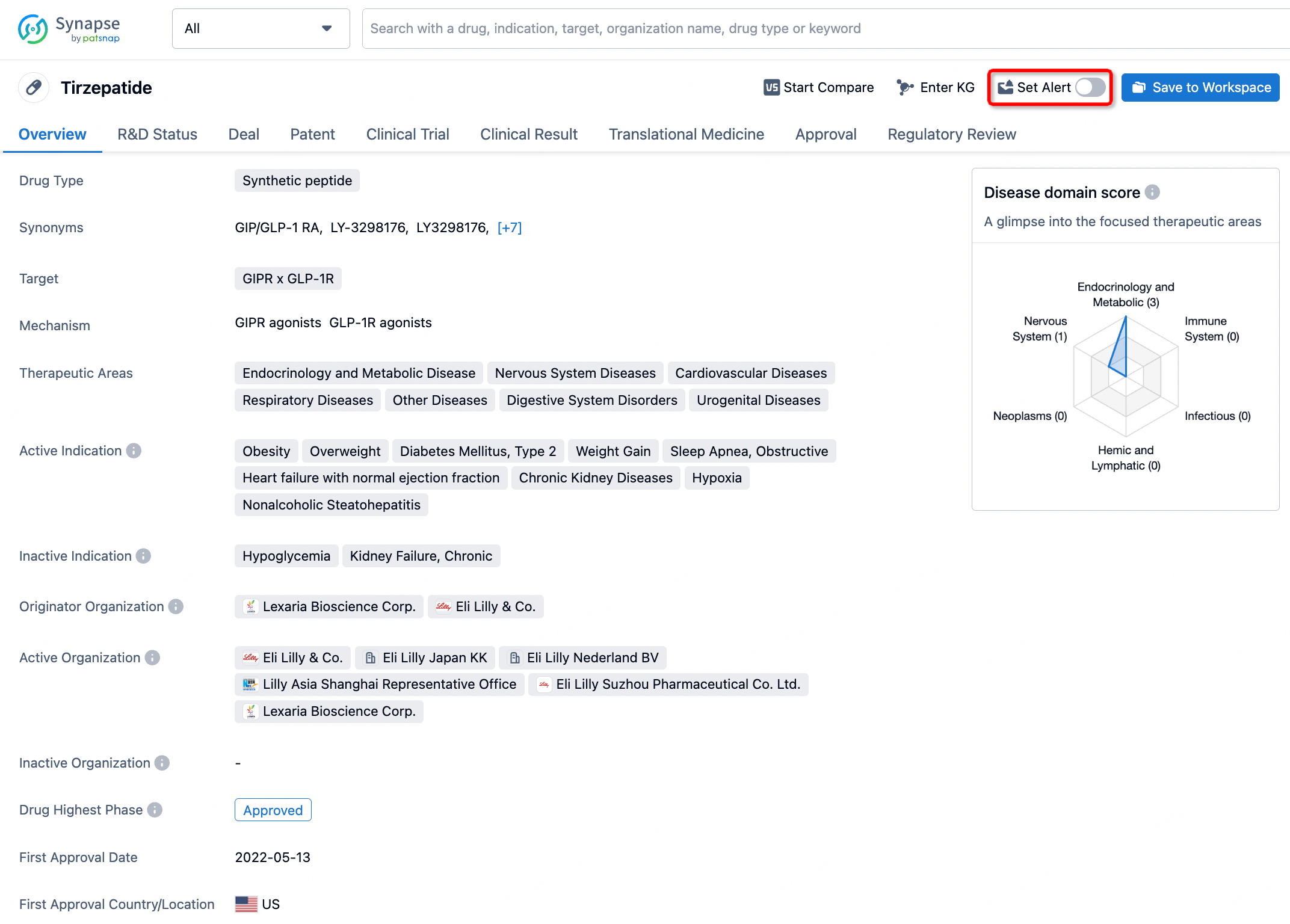

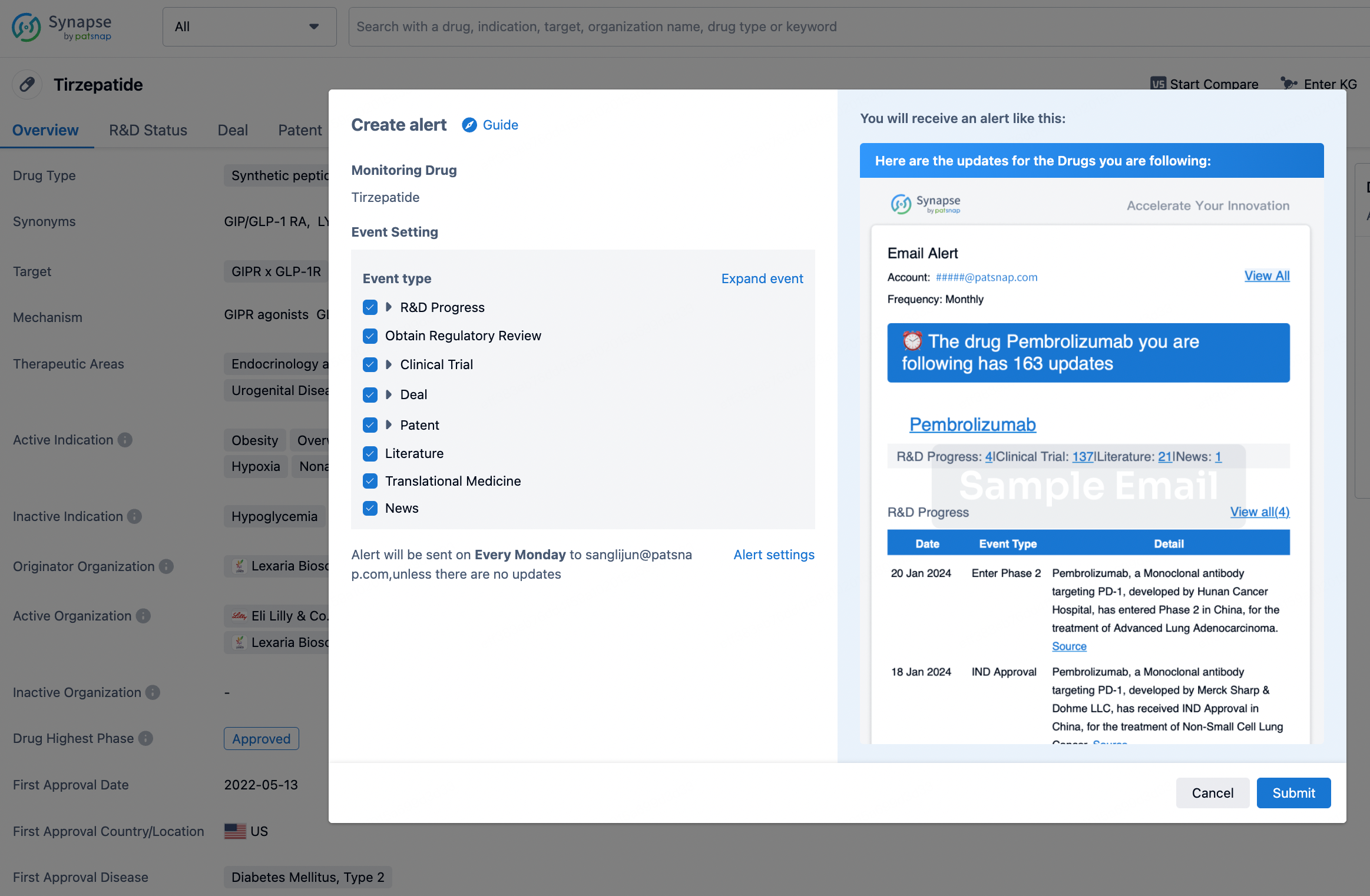

How to obtain the latest development progress of all drugs?

In the Synapse database, you can stay updated on the latest research and development advances of all drugs. This service is accessible anytime and anywhere, with updates available daily or weekly. Use the "Set Alert" function to stay informed. Click on the image below to embark on a brand new journey of drug discovery!

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.