Request Demo

Last update 26 Nov 2025

Indian Institute of Technology Madras

Last update 26 Nov 2025

Overview

Tags

Nervous System Diseases

Skin and Musculoskeletal Diseases

Other Diseases

Small molecule drug

Disease domain score

A glimpse into the focused therapeutic areas

No Data

Technology Platform

Most used technologies in drug development

No Data

Targets

Most frequently developed targets

No Data

| Disease Domain | Count |

|---|---|

| Nervous System Diseases | 2 |

| Top 5 Drug Type | Count |

|---|---|

| Small molecule drug | 3 |

| Top 5 Target | Count |

|---|---|

| AHR(Aryl hydrocarbon receptor) | 1 |

Related

3

Drugs associated with Indian Institute of Technology MadrasTarget |

Mechanism AHR antagonists |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhasePreclinical |

First Approval Ctry. / Loc.- |

First Approval Date- |

WO2024241327

Patent MiningTarget- |

Mechanism- |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhaseDiscovery |

First Approval Ctry. / Loc.- |

First Approval Date- |

IN202541077293

Patent MiningTarget- |

Mechanism- |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhaseDiscovery |

First Approval Ctry. / Loc.- |

First Approval Date- |

2

Clinical Trials associated with Indian Institute of Technology MadrasISRCTN11970082

An academic multicentre open-label single-arm study to record the efficacy of indomethacin among confirmed COVID-19 patients with mild and moderate symptoms

Start Date16 Aug 2020 |

Sponsor / Collaborator |

CTRI/2020/01/022800

Clinical Validation of Practicability of Capacitive ECG Measurement for Ubiquitous Healthcare

Start Date01 Feb 2020 |

Sponsor / Collaborator |

100 Clinical Results associated with Indian Institute of Technology Madras

Login to view more data

0 Patents (Medical) associated with Indian Institute of Technology Madras

Login to view more data

15,984

Literatures (Medical) associated with Indian Institute of Technology Madras01 Jan 2026·FUEL

Hypergolic aluminized fuels with rocket-grade hydrogen peroxide: A comprehensive study of the ignition delay, energetics, thermo-physical properties, mechanical properties and storability

Author: Sahul Kumar, V. S. ; Ramakrishna, P. A.

A novel class of metalized hypergolic fuels, termed Hypergolic Aluminized Fuel (HAF), was developed and tested for ignition with 90 weight% H2O2 as the oxidizer.Using NASA-CEA software, two compositions, HAF-7 and HAF-8, were identified based on their high d.-specific impulse, low oxidizer to fuel (O/F) ratio and manufacturability.Despite a high solid loading (≥70 weight%) both fuels exhibited excellent d. recovery ( > 98 %) and good mech. properties (Shore-A hardness > 80).For the first time, ignition delay time (IDT) was systematically examined under varying storage conditions, including vacuum and exposure to humidity, as well as different surface preparations (sanded and not-sanded) for these fuels.Results indicated that prolonged exposure to humidity increased the IDT due to fuel mass gain and reductant degradationA correlation between IDT and fuel mass gain (precipitation) was established, confirming the adverse effects of humidity on ignition performance.Thermal anal. revealed that the HAFs possess a good thermal conductivity when compared to composite solid propellants.Structural characterization using SEM/EDS detected microstructural changes upon exposure to humidity, while PXRD anal. identified phase changes due to oxide formation.Though there are challenges, HAFs maintained an IDT below 5 ms, validating its hypergolic reliability.Reignition tests, which are vital for this class of propellants exhibited minimal IDT variations, confirming repeatability.Notably, HAFs, with high additive loading and no catalyst, demonstrated an IDT range better than those obtained with solid hypergolic fuels made from paraffin wax and other thermoplastics, making it a promising candidate for propulsion applications.Lastly, these HAFs have certain limitations like the lack of long-term storage stability when exposed to humidity effects.However, while HAF-8 exhibited improved performance, HAF-7 showed a better long-term stability, highlighting a trade-off between energetics and chem. stability.

31 Dec 2025·mAbs

YAbS: The Antibody Society’s antibody therapeutics database

Article

Author: Rawat, Puneet ; Crescioli, Silvia ; Sharma, Divya ; Reichert, Janice M. ; Greiff, Victor ; Prabakaran, R.

Therapeutic antibodies have gained prominence in recent years due to their precision in targeting specific diseases. As these molecules become increasingly essential in modern medicine, comprehensive data tracking and analysis are critical for advancing research and ensuring successful clinical outcomes. YAbS, The Antibody Society's Antibody Therapeutics Database, serves as a vital resource for monitoring the development and clinical progress of therapeutic antibodies. The database catalogs detailed information on over 2,900 commercially sponsored investigational antibody candidates that have entered clinical study since 2000, as well as all approved antibody therapeutics. Data for the late-stage clinical pipeline and antibody therapeutics in regulatory review or approved (over 450 molecules) are openly accessible (https://db.antibodysociety.org). Antibody-related information includes molecular format, targeted antigen, current development status, indications studied, and the clinical development timeline of the antibodies, as well as the geographical region of company sponsors. Furthermore, the database supports in-depth industry trends analysis, facilitating the identification of innovative developments and the assessment of success rates within the field. This resource is continually updated and refined, providing invaluable insights to researchers, clinicians, and industry professionals engaged in antibody therapeutics development.

31 Dec 2025·Green Chemistry Letters and Reviews

Treatment of industrial dye effluent: a pre-pilot plant scale study based on circular liquid–liquid extraction using pseudoprotic ionic liquids

Author: Govindaraj, Jegan ; Gardas, Ramesh L. ; Padinhattath, Sachind Prabha

The hazardous chems. discharged from various dyeing industries adversely impact human health and the environment.Therefore, it is essential to treat wastewater containing dyes with technol. that outperforms conventional methods.In the current study, liquid-liquid extraction (LLE) based on pseudoprotic ionic liquids (PPILs) was employed as an efficient tool to remove anionic dyes from simulated and real dye effluent.PPIL derived from trioctylamine and octanoic acid was used for the extraction studies.Initially, simulated dye samples were prepared using different anionic dyes, namely alizarin yellow, rose Bengal, and methyl orange, identical to the real industrial dye effluent composition, and LLE studies were carried out.After a series of screenings, the essential exptl. parameters required for deploying a pre-pilot plant scale study have been optimized systematically.After successful optimization, similar exptl. parameters were deployed for the removal of dyes from the industrial dye effluent collected from Angeripalayam common effluent treatment plant limited (ACETP), Tirupur, Tamil Nadu, India.While most optimized reaction conditions remained unaltered, adjustments were made to some, such as pH, to suit practical scenarios.Moreover, the dyes were back-extracted with dilute diethylamine and the regenerated extractant was reused in subsequent LLE cycles.

7

News (Medical) associated with Indian Institute of Technology Madras05 May 2023

Bonatra expanding chronic disease management platform with MyAva acquisition

Bonatra, which is once focused on treating chronic health conditions in men, is expanding its platform to deal with women's health and wellness through its latest acquisition of MyAva.

Founded in 2019, the femtech startup provides curated programmes and personalised plans to help women manage their chronic conditions, including PCOS and thyroid disorders.

"Acquiring MyAva enables us to expand our reach and deepen our expertise in women’s health, specifically for conditions like PCOS," said Bonatra CEO and co-founder Rahul Kishore Singh. Bonatra offers personalised treatment plans based on IoMT-collected data to help men treat and manage their chronic conditions, such as hypertension and diabetes.

MyAva CEO and founder said they are elated to join Bonatra and "further the vision of making chronic care management accessible to all women" while strengthening their joint commitments to "making femtech more inclusive and integrated."

Startoon gets US FDA clearance for wearable recovery tracking device

Indian medical device startup Startoon Labs has received the United States Food and Drug Administration's 510(k) clearance for its flagship wearable health product.

Called Pheezee, the device measures the surface electromyogram of bulk muscles and the range of motion of primary joints to determine joint health. It is intended for use in tracking patients' recovery from physiotherapy, neurological, and musculoskeletal injuries.

Indian researchers use ML to detect CNS tumours

Researchers at the Indian Institute of Technology Madras have developed an ML-based computational tool to better detect cancer-causing tumours in the brain and spinal cord.

Available publicly online, the GBMDriver (GlioBlastoma Mutiforme Drivers) identifies driver mutations and passenger mutations in glioblastoma, which are key to developing therapeutic options for patients.

Ubie expands rare diseases partnership with Takeda

Japanese health tech startup Ubie has expanded its digital transformation partnership with Takeda Pharmaceutical Co.

The expanded collaboration, according to a press statement, seeks to promote the early detection of rare diseases and gastrointestinal diseases. The two companies started their partnership in 2021 with the promotion of Ubie's symptom checker and patient intake form.

Ubie also intends to introduce additional functions on top of its current offerings and to collaborate with Takeda on IT systems and data.

Drug ApprovalAcquisition

24 Mar 2023

Lunit obtains new CE mark for AI DBT solution

South Korean medical AI company Lunit has received a CE mark under Europe's latest Medical Device Regulation for its AI software for digital breast tomosynthesis (DBT) analysis.

Called Lunit INSIGHT DBT, the software solution analyses 3D images from DBT, enabling fast and accurate diagnosis of breast cancer.

In a press statement, Lunit disclosed its plan to start rolling out the software product in Europe by the end of March, noting an uptick in interest. It also announced its plan to begin the process of acquiring the US FDA's approval for Lunit INSIGHT DBT in the third quarter. The technology has already been approved for commercialisation in South Korea early this year.

Jolly Good creates emergency care VR content with Brigham and Women's Hospital

Jolly Good has revealed its latest collaboration with Harvard Medical School-affiliated Brigham and Women's Hospital (BWH).

According to a press statement, their partnership seeks to verify the educational benefits of medical VR and its implementation in North America.

As part of their collaboration, the organisations have developed VR content on emergency care.

Meanwhile, the Japanese VR company announced that Dr Kei Ouchi, associate professor at Harvard Medical School, has become its medical advisor who will guide its full entry into the US medical market.

IIT Madras researchers develop coronavirus antibodies database

Researchers from the Indian Institute of Technology Madras (IIT Madras) have built an open-source database of coronaviruses' antibodies.

Called Ab-CoV, the online database includes antibody features such as binding affinity and neutralisation profiles, source, and identifying viral proteins and strains. Currently, Ab-CoV has data on 1,780 coronavirus-related antibodies and contains more than 3,200 data points on their features.

"Ab-CoV is an exhaustive repository of antibodies, not just specific to SARS-CoV-2, but also to other members of the coronavirus family, such as SARS and MERS viruses," Dr Vani Janakirama of the Department of Biotechnology explained.

Based on a press statement, the Ab-CoV database can be used to aid the development of new drugs against emerging variants of SARS-CoV-2, the virus which causes COVID-19.

"This repository would aid in comparative studies among different neutralising antibodies across coronaviruses and assess their properties and interaction patterns with epitopes on the native and mutant viral proteins. Such an effort eventually would help to gauge the efficacy of these antibodies towards existing and emerging viral variants," Dr Janakirama added.

25 Nov 2022

IIT Madras develops IT tool to improve rural health

The Indian Institute of Technology Madras (IIT Madras) has created an IT tool to monitor and improve the health of Scheduled Caste (SC) communities in Andhra Pradesh.

It was deployed for a project in E. Palaguttapalli SC in the Chittoor district where it was used to gather detailed household-level health-related information year-round and to make an objective assessment of the impact of medical treatment and dietary advice on major health conditions.

The project also organised online live interactions every other month where special lectures on improving one's health were delivered.

Following this pilot, IIT Madras researchers plan to build a mobile application to digitise health status monitoring and mapping in SC communities.

AIIMS New Delhi to go all digital for payments

All India Institute of Medical Sciences New Delhi (AIIMS New Delhi) will be implementing all-digital payments at its counters starting in April next year.

The public medical university and hospital is setting up a smart card facility to enhance the payment experience for patients. It will be integrated with its existing billing facility with arrangements to be made for instalment payments.

Once the facility goes live, no cash payment shall be accepted at the counters of AIIMS New Delhi other than its smart card. Top-up counters will also be installed at different locations within OPDs.

ASUS, Octopian to bring AI medical coding solutions to the Middle East

IT providers ASUS and Octopian have tied up to deliver an integrated cloud solution for optimising revenue cycle management in the Middle East.

This collaboration will see ASUS's AI-powered coding assistant Miraico integrated with the Octopian Cloud platform. The resulting solution will help healthcare providers analyse medical terms in clinical records and automatically suggest appropriate ICD-10 codes to optimise Diagnosis-Related Group assignments and enhance hospital operations.

According to a press release, this integrated offering will first come to Saudi Arabia and the United Arab Emirates.

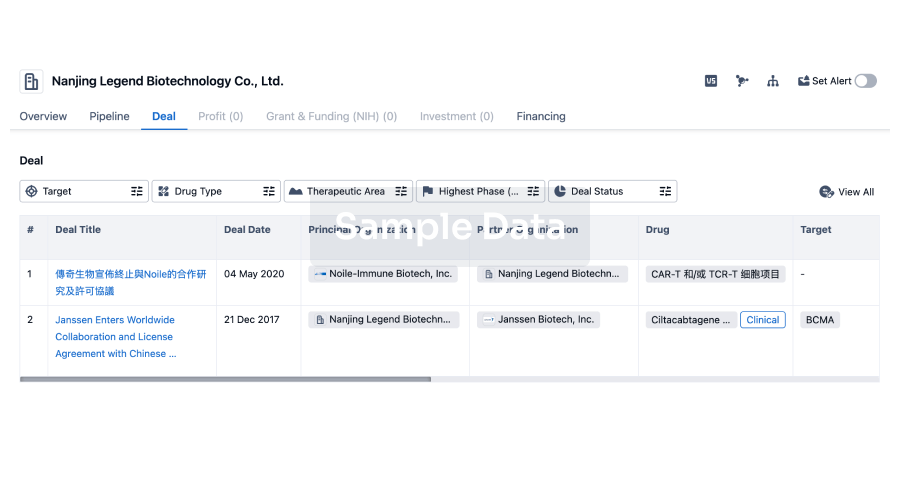

100 Deals associated with Indian Institute of Technology Madras

Login to view more data

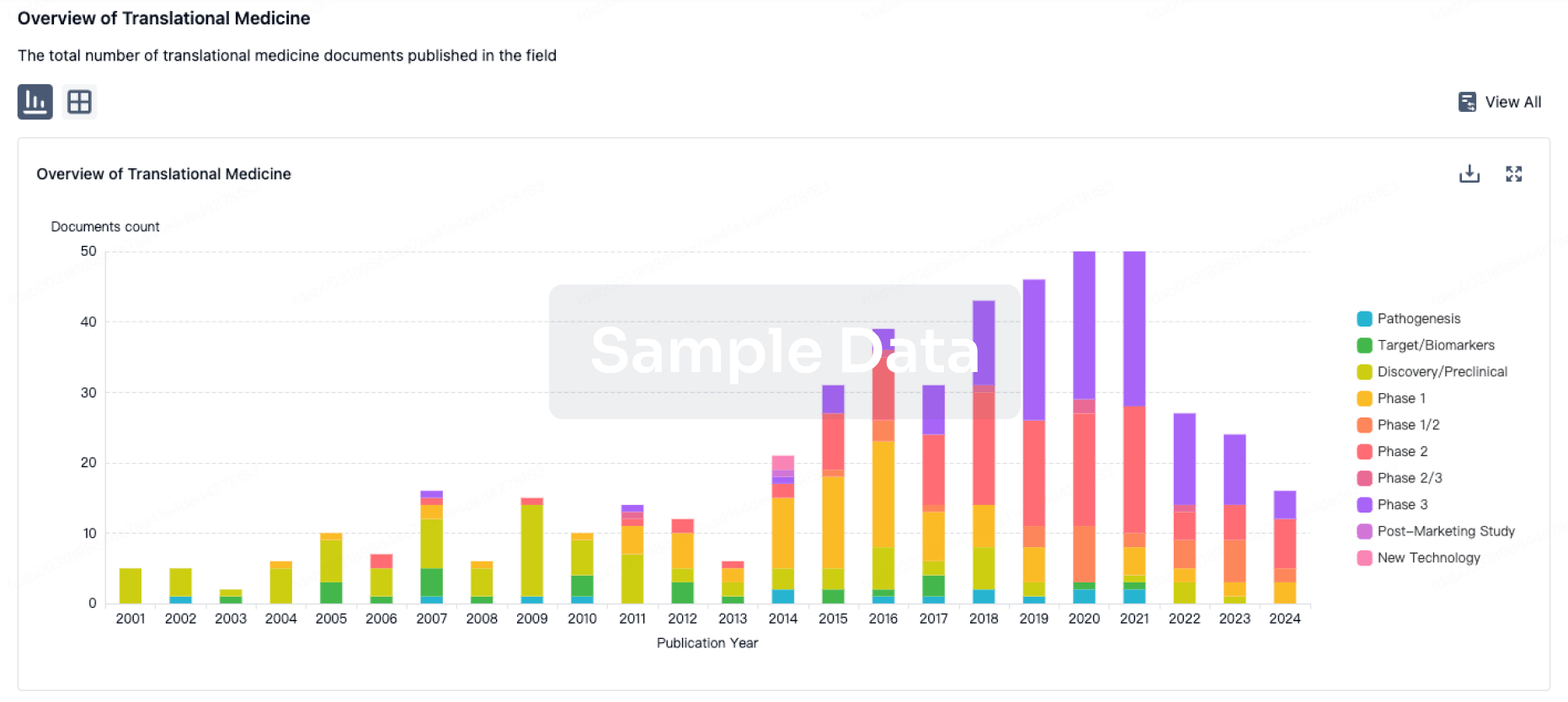

100 Translational Medicine associated with Indian Institute of Technology Madras

Login to view more data

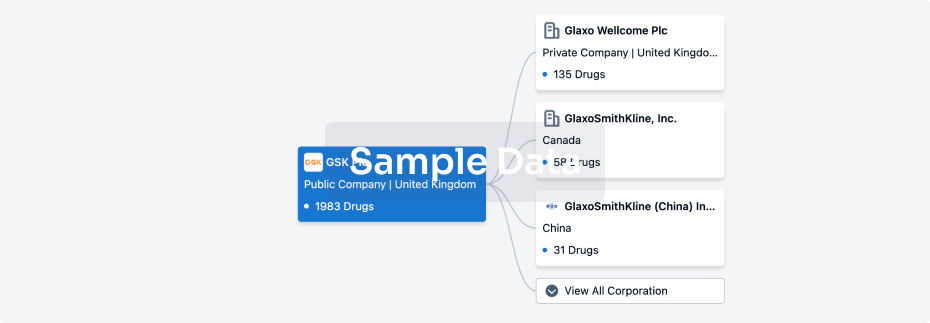

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 18 Dec 2025

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Discovery

2

1

Preclinical

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

SG-02 ( AHR ) | Muscular Dystrophy, Duchenne More | Preclinical |

WO2024241327 Patent Mining | Nervous System Diseases More | Discovery |

IN202541077293 Patent Mining | Skin and Musculoskeletal Diseases More | Discovery |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

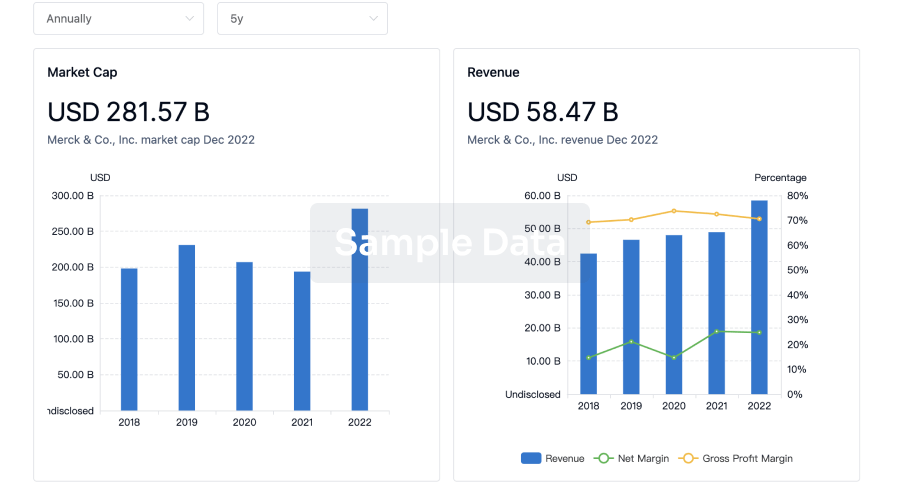

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

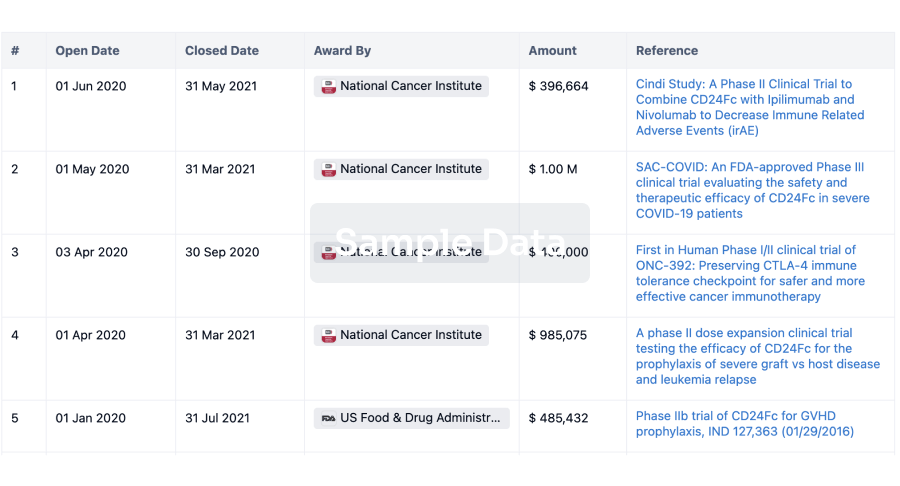

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

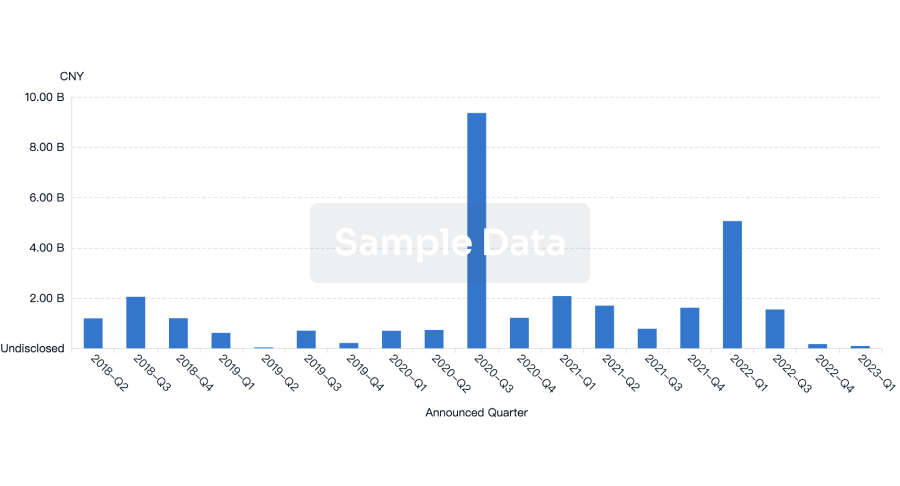

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

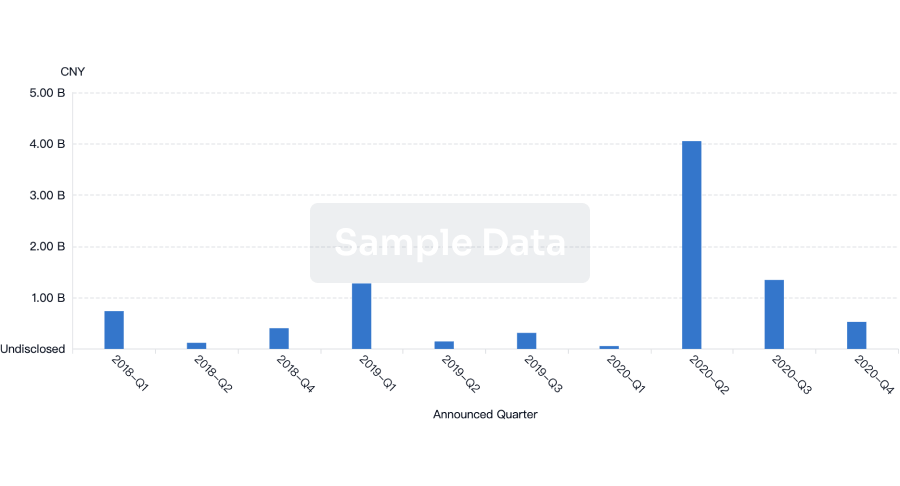

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free