Request Demo

Last update 08 May 2025

JSR Life Sciences LLC

Last update 08 May 2025

Overview

Tags

Monoclonal antibody

Biosimilar

Disease domain score

A glimpse into the focused therapeutic areas

No Data

Technology Platform

Most used technologies in drug development

No Data

Targets

Most frequently developed targets

No Data

| Top 5 Drug Type | Count |

|---|---|

| Biosimilar | 1 |

| Monoclonal antibody | 1 |

| Top 5 Target | Count |

|---|---|

| TNF-α(Tumor necrosis factor α) | 1 |

Related

1

Drugs associated with JSR Life Sciences LLCTarget |

Mechanism TNF-α inhibitors |

Active Org. |

Originator Org. |

Active Indication- |

Inactive Indication- |

Drug Highest PhasePreclinical |

First Approval Ctry. / Loc.- |

First Approval Date- |

100 Clinical Results associated with JSR Life Sciences LLC

Login to view more data

0 Patents (Medical) associated with JSR Life Sciences LLC

Login to view more data

27

Literatures (Medical) associated with JSR Life Sciences LLC31 Dec 2024·mAbs

Seq2scFv: a toolkit for the comprehensive analysis of display libraries from long-read sequencing platforms

Article

Author: Schmid-Siegert, Emanuel ; Arpat, Bulak ; Santuari, Luca ; Lykoskoufis, Nikolaos ; Xenarios, Ioannis ; Bachmann Salvy, Marianne

01 May 2023·The Journal of Immunology

An in vitro T cell Dysfunction/Exhaustion Assay System that is partially reversible by pembrolizumab

Author: Kleiman, Eden ; Daftarian, Pirouz M ; Goverse, Gera ; King, Jeffrey

01 May 2020·The Journal of Immunology

Novel approach for the detection of antigen-specific CD8 T cell responses corresponding to treatment outcome in HPV+ cancer patients

Author: Sierra, Gloria ; Daftarian, Pirouz ; Ouerkaxi, Wushouer ; George, Marybeth ; Delcommenne, Marc ; Sastry, Jagannadha K

46

News (Medical) associated with JSR Life Sciences LLC11 Dec 2024

SAN DIEGO--(

BUSINESS WIRE

)--Crown Bioscience, a global contract research organization (CRO) headquartered in the United States and a part of JSR Life Sciences and Japan-based JSR Corporation, has been honored with the 2024 Fierce CRO Award for Excellence in Client Service and Partnership. This prestigious award recognizes Crown Bioscience's outstanding collaboration, communication, and commitment to delivering excellence for its life sciences clients.

The Fierce CRO Awards, hosted annually by Fierce Biotech, celebrate the achievements of leading CROs that demonstrate innovation and leadership in accelerating drug development. Winners in this category are selected based on their commitment to building strong partnerships and providing an exceptional client experience.

"Winning this award is a true testament to our team’s dedication to going above and beyond for our clients," said Dr. Jonny McMichael, Vice President of Client Experience and Enablement at Crown Bioscience. "We aim to accelerate the journey of new therapies by collaborating closely with our partners across the drug development continuum."

Crown Bioscience stood out for its innovative preclinical research capabilities, transparent communication practices, and unwavering focus on delivering quality and value to clients. Specific achievements highlighted include the company's

Customer Satisfaction Program

, which generates unfiltered feedback scores to demonstrate its commitment to service and customer excellence.

"This recognition motivates us to continue raising the bar for the CRO industry," Dr. McMichael added. "We are thankful to our entire team for making Crown Bioscience a trusted, client-focused partner in the mission to bring new treatments to patients faster and more efficiently."

The full Fierce CRO Awards report profiling all winners is available

here

. Crown Bioscience's award-winning capabilities can be explored at

www.crownbio.com

.

About Crown Bioscience

Crown Bioscience, a JSR Life Sciences company, is a global Contract Research Organization (CRO) dedicated to improving human health through partnering with biotech and pharmaceutical companies that drive the discovery and development of oncology drugs. We exclusively offer preclinical tumor organoid services using the well-established Hubrecht Organoid Technology, with over 600 organoid models available spanning 22 cancer indications. In addition, we have developed the world’s largest commercially available PDX collection. Further committed to personalized medicine, our subsidiary, Indivumed Services, maintains an extensive biobank of liquid and tissue human biospecimens. Our focus on helping our customers develop novel therapies aims to ensure that patients receive the right treatment at the right time. Founded in 2006, we have 12 facilities across the US, Europe, and Asia. For more information, please visit

www.crownbio.com

21 Aug 2024

SAN DIEGO--(

BUSINESS WIRE

)--

Crown Bioscience

, a global contract research organization (CRO) and a JSR Life Sciences company, today announced a strategic partnership with Clinical Trial & Consulting Services (CTI), a renowned global full-spectrum research service provider, to bolster oncology-focused consulting services. This collaboration unites decades of expertise from both organizations in oncology drug discovery and development, leveraging Crown Bioscience’s preclinical and translational models and CTI’s well-established track record in the clinical and regulatory space.

Customers will benefit from combined expert guidance, supporting the transition of oncology compounds from discovery through early-phase clinical trials more rapidly and effectively. This alliance aims to determine the optimal and most expeditious path to the clinic, ensure long-term drug development success and growth, and accelerate the delivery of superior oncology therapeutics to patients.

From today, customers can access consulting services to ensure an integrated drug development approach, including:

Strategic preclinical development planning

Study data analysis, interpretation and advice

Regulatory guidance

De novo

assay development

Grant review

Alex Slater, Senior Vice President of Commercial, commented:

‘’Crown Bioscience has an established reputation for exceeding the typical services offered by a regular CRO. This initiative unites deep-seated expertise spanning all phases of drug development, marking a pivotal step towards delivering a true translational offer to our clients.’’

Ryan Gifford, Vice President of Global Laboratory Services, Business Development, shares:

‘’We are delighted to collaborate with Crown Bioscience and view this as a valuable synergy. Crown Bioscience’s leadership in early-phase oncology research and suite of preclinical services complement CTI’s broad spectrum of capabilities. Together, we can offer enhanced support to our oncology clients and deepen our commitment to advancing cancer research.’’

About Crown Bioscience

Crown Bioscience, a JSR Life Sciences company, is a global Contract Research Organization (CRO) dedicated to improving human health through partnering with biotech and pharmaceutical companies that drive the discovery and development of oncology drugs. We exclusively offer preclinical tumor organoid services using the well-established Hubrecht Organoid Technology, with over 600 organoid models available spanning 22 cancer indications. In addition, we have developed the world’s largest commercially available PDX collection. Further committed to personalized medicine, our subsidiary, Indivumed Services, maintains an extensive biobank of liquid and tissue human biospecimens. Our focus on helping our customers develop novel therapies aims to ensure that patients receive the right treatment at the right time. Founded in 2006, we have 12 facilities across the US, Europe, and Asia. For more information, please visit

www.crownbio.com

About CTI Clinical Trial & Consulting Services

CTI Clinical Trial and Consulting Services is a global, privately held, research service organization, delivering a complete spectrum of clinical trial and consulting services throughout the lifecycle of development, from concept to commercialization. CTI’s focused therapeutic approach provides clinical and disease area expertise with nuanced regulator support. CTI also offers a fully integrated multi-specialty clinical research site and complete global laboratory services. Now in its third decade, CTI is one of the 20 largest contract research organizations in the world, with associates in more than 60 countries across six continents. CTI is headquartered in the Greater Cincinnati area, with operations across North America, Europe, Latin America, MEA, and Asia-Pacific. For more information, visit

www.ctifacts.com

.

Clinical Study

23 Jul 2024

DURHAM, N.C.--(

BUSINESS WIRE

)--KBI Biopharma, Inc. (KBI), a JSR Life Sciences company and global cGMP contract development and manufacturing organization (CDMO), today announced that it has extended and expanded its manufacturing contract with a leading global pharmaceutical company. Originally initiated in 2020, the renewed contract extends through 2029 with a notable amendment that outlines a purchase commitment for two therapeutic products representing an incremental value of approximately $250 million through the end of the renewed term.

In addition, KBI, in late June, completed a successful regulatory inspection by the U.S. Food and Drug Administration (FDA) of its mammalian operation in Durham, North Carolina. This regulatory inspection enables the company’s North Carolina operations to begin providing a mammalian drug substance commercially to one of its key strategic customers. It also demonstrates KBI’s ability to act as a preferred partner for large volume commercial therapeutic manufacturing.

“As KBI continues fulfilling its commitment to our customers in helping solve their complex manufacturing challenges, this commercial contract extension allows us to demonstrate our approach as a next-generation CDMO,” said J.D. Mowery, President and CEO of KBI Biopharma. “With this agreement as well as our successful FDA regulatory inspection, we’re driving breakthroughs in biopharmaceutical development and manufacturing that help bring new therapies to market.”

He concluded, “By establishing these trusted, long-term partnerships with global pharmaceutical leaders, we’re able to positively impact the lives of patients worldwide.”

About KBI Biopharma, Inc.

KBI Biopharma, Inc., a JSR Life Sciences company, together with its affiliates, is a global contract development and manufacturing organization (CDMO) providing fully integrated, accelerated drug development and biologics manufacturing services and expertise to life science companies. As a global leader in mammalian cell line development, with best-in-class modular technology and highly specialized solutions, KBI enables the life sciences industry to rapidly discover, develop, and commercialize innovative medicines and vaccines. With each of its 500+ customer partners, KBI works closely to personalize and rapidly accelerate drug development programs.

Global partners are utilizing KBI’s technologies to advance more than 160 drug candidates in preclinical and clinical development and the manufacture of ten commercial products. Built upon a foundation of world-class analytics capabilities and extensive scientific and technical expertise, KBI delivers robust process development and clinical and commercial cGMP manufacturing services for mammalian and microbial programs. Recognized for quality manufacturing, KBI helps partners advance drug candidates to the market. KBI serves its global customers with six locations in Europe and the USA. More information is available at

www.kbibiopharma.com

.

Vaccine

100 Deals associated with JSR Life Sciences LLC

Login to view more data

100 Translational Medicine associated with JSR Life Sciences LLC

Login to view more data

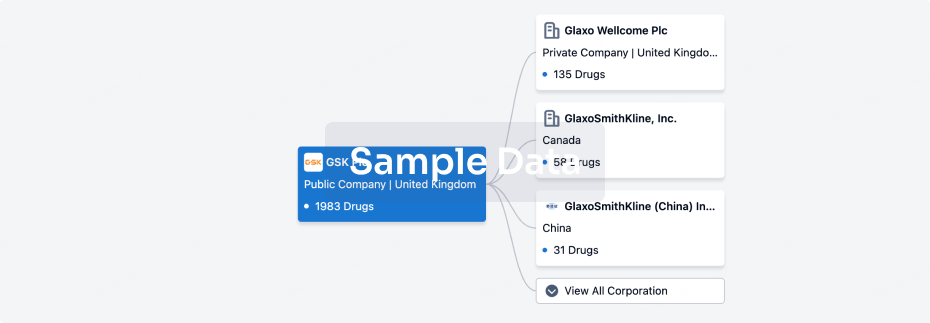

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 23 Feb 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Preclinical

1

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

Adalimumab Biosimilar(Similis Bio) ( TNF-α ) | - | Preclinical |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

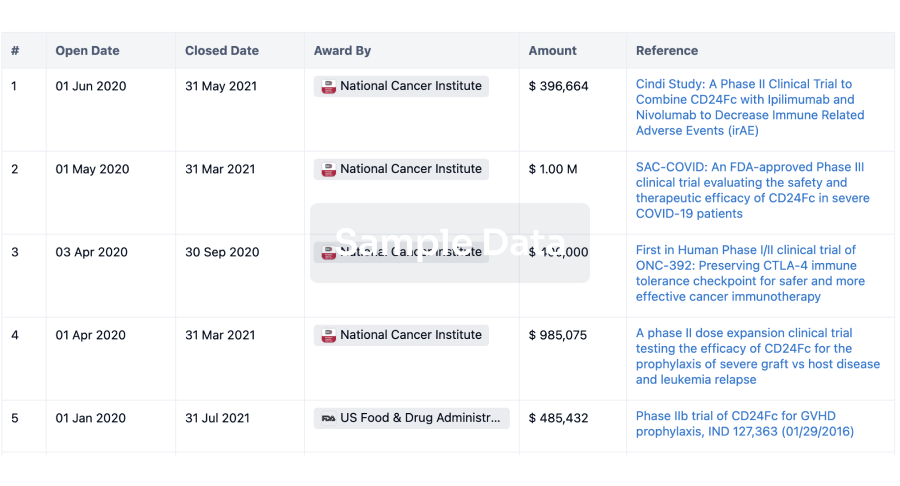

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free