Request Demo

Last update 08 May 2025

EMS SA (Brazil)

Last update 08 May 2025

Overview

Tags

Endocrinology and Metabolic Disease

Nervous System Diseases

Otorhinolaryngologic Diseases

Small molecule drug

Chemical drugs

Disease domain score

A glimpse into the focused therapeutic areas

No Data

Technology Platform

Most used technologies in drug development

No Data

Targets

Most frequently developed targets

No Data

| Top 5 Drug Type | Count |

|---|---|

| Small molecule drug | 6 |

| Chemical drugs | 2 |

| Unknown | 2 |

| Top 5 Target | Count |

|---|---|

| NET x μ opioid receptor | 1 |

Related

30

Drugs associated with EMS SA (Brazil)Target |

Mechanism Lipase inhibitors |

Active Org. |

Originator Org. |

Inactive Indication |

Drug Highest PhaseApproved |

First Approval Ctry. / Loc. European Union [+3] |

First Approval Date29 Jul 1998 |

Target |

Mechanism UL30 inhibitors [+1] |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication |

Drug Highest PhaseApproved |

First Approval Ctry. / Loc. United States |

First Approval Date29 Jun 1994 |

87

Clinical Trials associated with EMS SA (Brazil)NCT05125978

National, Multicenter, Randomized, Double-blind, Triple-dummy, Phase II Clinical Trial to Evaluate the Efficacy and Safety of Canadá Association in the Treatment of Chronic Pain

The purpose of this study is to evaluate the efficacy and safety of Canadá association in the treatment of chronic pain

Start Date01 Sep 2026 |

Sponsor / Collaborator |

NCT06272409

Phase III, Multicenter, Double-blind, Planned, Parallel Clinical Trial to Evaluate the Efficacy and Safety of DEP114 in the Treatment of Moderate to Severe Persistent Allergic Rhinitis in Children Aged Between 6 and 11 Years

The purpose of this study is to evaluate the efficacy and safety of DEP114 in the treatment of Moderate to Severe Persistent Allergic Rhinitis in children aged between 6 and 11 years.

Start Date15 Feb 2025 |

Sponsor / Collaborator |

NCT06237231

Phase III, Multicenter, Double-blind, Triple-dummy, Randomized, Parallel Clinical Trial to Evaluate the Efficacy and Safety of DIT112 in the Treatment of Moderate to Severe Pain After Dental Surgery for the Extraction of Impacted Third Molars

The purpose of this study is to evaluate the efficacy and safety of DIT112 in adolescents and adults with acute pain after dental surgery for the extraction of impacted third molars.

Start Date15 Feb 2025 |

Sponsor / Collaborator |

100 Clinical Results associated with EMS SA (Brazil)

Login to view more data

0 Patents (Medical) associated with EMS SA (Brazil)

Login to view more data

2

Literatures (Medical) associated with EMS SA (Brazil)01 Mar 2024·The American Journal of Cardiology

Cardiovascular Safety of Azithromycin in Patients Hospitalized With COVID-19: A Prespecified Pooled Analysis of the COALITION I and COALITION II Randomized Clinical Trials

Article

Author: Amazonas, Roberto ; Avezum, Alvaro ; Lisboa, Thiago ; Berwanger, Otavio ; Junqueira, Debora L M ; Serpa-Neto, Ary ; Azevedo, Luciano C P ; Correa, Thiago D ; Polanczyk, Carisi A ; Olivato, Guilherme B ; Fonseca, Henrique A R ; Zampieri, Fernando G ; Furtado, Remo H M ; Monfardini, Frederico ; Veiga, Viviane C ; Lopes, Renato D ; Guimarães, Hélio P ; Pereira, Adriano J ; Hoffman Filho, Conrado R ; Cavalcanti, Alexandre B ; Machado, Flávia R ; Lapa, Maura G ; Rohde, Luis E ; Barros E Silva, Pedro G M ; Gebara, Otavio E ; Echenique, Leandro S ; Damiani, Lucas P ; Rosa, Regis G

19 Nov 2020·New England Journal of MedicineQ1 · MEDICINE

Hydroxychloroquine with or without Azithromycin in Mild-to-Moderate Covid-19

Q1 · MEDICINE

Article

Author: Zampieri, Fernando G ; Serpa-Neto, Ary ; Berwanger, Otavio ; Rosa, Regis G ; Marcadenti, Aline ; Gebara, Otávio C E ; Hoffmann Filho, Conrado R ; Damiani, Lucas P ; Furtado, Remo H M ; Falavigna, Maicon ; Abreu-Silva, Erlon O ; Soares, Aline T ; Lopes, Renato D ; Lisboa, Thiago ; Amazonas, Roberto B ; Cardoso, Fábio F ; de Barros E Silva, Pedro G M ; Azevedo, Luciano C P ; Veiga, Viviane C ; Echenique, Leandro S ; Laranjeira, Ligia N ; Kawano-Dourado, Letícia ; Pereira, Adriano J ; Bocchi de Oliveira, Monalisa F ; Maia, Israel S ; Dantas, Vicente C S ; Machado, Flávia R ; Golin, Nicole A ; Avezum, Alvaro ; Kormann, Adrian P M ; Cavalcanti, Alexandre B ; Milan, Eveline P ; Freitas, Flávio G R ; Junqueira, Debora L M ; Tramujas, Lucas

4

News (Medical) associated with EMS SA (Brazil)17 Mar 2023

EMS Partners with the Alliance for Innovation to support transport, scalable training, and delivery of rehabilitation, telehealth and PTSD services for Ukrainian trauma patients.

WASHINGTON, March 17, 2023 /PRNewswire/ -- Education Management Solutions, the industry leader in healthcare education solutions, announces sponsorship of the Alliance for Innovation's Center of Excellence for Polytrauma. The Center will focus on three core humanitarian missions designed to address the most acute trauma treatment needs of soldiers in the Ukrainian conflict. First – provide prosthetics for wounded and amputee soldiers, paired with critical rehabilitation and mental health services. Second – establish the core logistics and protocols for the safe and efficient transport of patients across the Ukrainian-Polish border. Third – develop protocols and processes to facilitate the safe transport of patients back across the border, supplemented with an affordable and scalable training plan to develop clinicians and deliver telehealth services. Combined, the three mission areas will ease acute needs and accelerate the number in qualified in-country clinical professionals to provide ongoing acute trauma care.

Continue Reading

"Globally – we have a critical shortfall in skilled clinicians - across all disciplines," said Matt Merino, CEO of EMS. He continued, "The patient need in Ukraine is staggering. There are less 50 skilled trauma surgeons across the entire region. We are pleased to have the opportunity to contribute both support and technology to drive a solution."

EMS sponsors Center of Excellence for Polytrauma to support acute combat trauma treatment for Ukraine warfighers.

Tweet this

The Alliance for Innovation will kick off their mission with a major fundraising event, Chopin – The Space Concert on Saturday, March 18, 2023, at the National Air and Space Museum's Steven F. Udvar-Hazy Center. The Center for Excellence in Polytrauma is a joint initiative involving multiple public and private partners including the Medical Society of Virginia, The National Center for PTSD, Department of Veterans Affairs, and Baylor College of Medicine.

About EMS:

Celebrating 30 years of innovation, Education Management Solutions (EMS) is a pioneer in simulation and competency-based learning for healthcare education and training. EMS provides turnkey education solutions, program management, design, installation, and 24/7 customer support for hundreds of universities, colleges, and healthcare systems worldwide.

SOURCE Education Management Solutions

28 Jun 2021

Dublin, June 28, 2021 (GLOBE NEWSWIRE) -- The "Global Automotive Plastics Market for Passenger Cars by Product Type (PP, PU, PVC, PA), Application (Interior, Exterior, Under Bonnet), Vehicle Type (Conventional Cars, Electric Cars), and Geography - Forecast to 2026" report has been added to ResearchAndMarkets.com's offering.

The global automotive plastics market for passenger cars is estimated at USD 21.1 billion in 2021 and is projected to reach USD 30.8 billion by 2026, at a CAGR of 7.9% during the forecast period of 2021 to 2026.

Increasing disposable income, changing lifestyles, and growing population in emerging economies are some of the growth drivers for the automotive plastics market for passenger cars.The under-bonnet application segment is projected to grow at the highest CAGR during the forecast periodBased on application, the under-bonnet application is the fastest-growing segment of the automotive plastics market for passenger cars. With the increasing demand for passenger cars, the demand for plastic powertrain components such as housing and electric motor casing is likely to increase.

Also, other factors responsible for the market growth include battery thermal management systems that require high-quality polymer casing and the deployment of lightweight components for electric motor. New plastic innovations in the electric powertrain such as adoption of polymer in the cooling concept of electric motor housing material are likely to result in the growth of advanced plastics used for under bonnet components.The PU product type segment is the largest market in 2020PU is the largest product type segment in the automotive plastics market for passenger cars. PU is a strong and light material that helps designers and manufacturers design seating and other components that can be assembled, disassembled, and recycled.

They are available in a wide range of stiffness, hardness, and densities, and are used in seats, steering wheels, automotive suspension bushings, carpet backing, seat overlays, head & armrests, airbag covers, acoustic insulations and insulation panels. Polyurethane is the most durable and can be recycled, thereby finding plenty of applications in automotive plastics for passenger cars.Polyurethanes help in improving the quality, safety, and cost-effectiveness of modern cars. The developing economies of APAC, such as China and India, are driving the demand for polyurethanes owing to the increase in car production in these countries.Asia Pacific is projected to grow the highest CAGR in the automotive plastics market for passenger cars during the forecast periodAsia Pacific is the largest and fastest-growing market in the automotive plastics market for passenger cars. It is the largest market because of the increased use of plastics in the vehicles produced in China, Japan and India.

The vehicle production in these countries is growing at a rapid rate because of the presence of major automotive players such as Honda, Toyota, Hyundai, Maruti Suzuki and Nissan. Manufacturers such as BMW and Volkswagen have already set up manufacturing units in these countries.In terms of geography, Asia has the highest sales of automotive, making it the largest market for plastic for passenger cars. Such factors are expected to fuel the growth of the automotive plastics market for passenger cars in the region.

Key Topics Covered:

1 Introduction2 Research Methodology3 Executive Summary4 Premium Insights4.1 Significant Opportunities In Automotive Plastics Market for Passenger Cars4.2 APAC Automotive Plastics Market for Passenger Cars, by Product Type, and Country4.3 Automotive Plastics Market for Passenger Cars, by Application4.4 Automotive Plastics Market for Passenger Cars, by Region4.5 Automotive Plastics Market for Passenger Cars Attractiveness

5 Market Overview5.1 Introduction5.2 Market Dynamics5.2.1 Drivers5.2.1.1 Adoption of lightweight materials due to stringent emission and fuel economy regulations5.2.1.2 Introduction of new safety features and luxury components5.2.1.3 OEMs' inclination towards thermally stable plastics5.2.2 Restraints5.2.2.1 Covid-19 slowing down sales of passenger cars5.2.3 Opportunities5.2.3.1 Use of bioplastics in vehicle production5.2.3.2 Use of anti-microbial plastics/additives in vehicle car production5.2.3.3 Use of composites and PMMA in vehicle car production5.2.3.4 Growing trend of vehicle electrification5.2.4 Challenges5.2.4.1 Shifting demands of OEMs for advanced materials to adhere to carbon emission targets5.2.4.2 High cost of capital and infrastructure for re-engineering of plastics5.3 Porter's Five forces Analysis5.3.1 Threat of Substitutes5.3.2 Threat of New Entrants5.3.3 Bargaining Power of Suppliers5.3.4 Bargaining Power of Buyers5.3.5 Intensity of Competitive Rivalry5.4 Impact of Covid-19 On Automotive Plastics Market for Passenger Cars5.4.1 Covid-195.4.2 Covid-19 Health Assessment5.4.3 Impact On Automotive Plastics Market for Passenger Cars5.5 Trends and Disruptions Impacting Customer's Business5.6 Ecosystem/Market Map of Automotive Plastics for Passenger Cars5.7 Patent Analysis5.8 Regulatory Landscape5.9 Case Study Analysis5.10 Pricing Analysis5.11 Technology Analysis5.12 Supply Chain Analysis

6 Automotive Plastics Market for Passenger Cars, by Product Type

7 Automotive Plastics Market for Passenger Cars, by Application

8 Automotive Plastics Market for Passenger Cars, by Vehicle Type

9 Automotive Plastics Market for Passenger Cars, by Region

10 Competitive Landscape

11 Company Profiles11.1 Key Players11.1.1 BASF SE11.1.2 Sabic11.1.3 Lyondellbasell Industries Holdings BV11.1.4 LG Chem11.1.5 Dupont11.1.6 Borealis AG11.1.7 Covestro AG11.1.8 Evonik Industries AG11.1.9 Royal DSM11.1.10 Arkema SA11.1.11 Solvay11.1.12 Lanxess11.1.13 Celanese Corporation11.1.14 Toray Industries Inc.11.1.15 Mitsui Chemicals11.2 Other Key Market Players11.2.1 Toyota Boshoku Corporation11.2.2 Faurecia SA11.2.3 Toyoda Gosei Co., Ltd.11.2.4 INEOS11.2.5 Sumito Chemicals Company Ltd.11.2.6 UBE Industries11.2.7 Mitsubishi Engineering Plastics Corporation11.2.8 Formosa Plastics Corporation11.2.9 EMS Chemi Holdings11.2.10 Momentive Performance Materials11.2.11 AGC Chemicals Americas Inc.11.2.12 Chevron Phillips Chemicals11.2.13 Braskem11.2.14 PTT Global Chemical11.2.15 Hanwha Chemical11.2.16 Stratasys11.2.17 APPL Industries Ltd.11.2.18 Kraiburg Holding GmbH & Co. Kg11.2.19 Saint-Gobain Group11.2.20 AG Industries Pvt. Ltd.

12 Appendix12.1 Discussion Guide12.2 Knowledge Store: The Subscription Portal12.3 Available Customizations12.4 Related Reports12.5 Author Details

For more information about this report visit

18 May 2020

Synergistic joint development and manufacturing capability expands market opportunity in surgical navigationProvides immediate access to technology platform serving new high growth medical end-markets with complex interventional catheters Accretive transaction delivers long-term revenue growth potential and diversifies customer baseARDEN HILLS, Minn., May 19, 2020 (GLOBE NEWSWIRE) -- IntriCon Corporation (NASDAQ: IIN), a designer, developer and manufacturer of miniature interventional, implantable and body-worn medical devices, today announced that it has completed the acquisition of privately held Emerald Medical Services (EMS) Pte Ltd. The acquisition expands IntriCon’s medical coil and micro-miniature medical device engineering and manufacturing capabilities in surgical navigation and accelerates diversification into potential new end markets.Emerald Medical Services, based in Singapore, provides joint engineering and manufacturing services for complex medical devices, including catheters covering a range of applications for cardiology, peripheral vascular, neurology, radiology and pulmonology. EMS’s production capability consists of design, development, manufacturing, testing and non-sterile packaging services.Under the terms agreement to acquire EMS, the transaction consideration consists of an upfront payment of approximately $7.1 million, 80,000 shares of IntriCon common stock, and a cash earnout based on the achievement of specific sales milestones over a three-year period.“As we sought opportunities to build on our core competencies as a miniature and micro-miniature device manufacturer, Emerald Medical Services stood out as an ideal strategic complement to our business,” said Mark Gorder, president and chief executive officer of IntriCon. “We have been familiar with their high-quality design, development and manufacturing services in the complex catheter space for some time. In addition, EMS’s existing technology expands our addressable market within surgical navigation and diversifies our customer base. This transaction combines two business that are dedicated to developing and manufacturing devices that support the advancement of medical technology,” concluded Gorder.“Emerald has made significant investments in developing a portfolio of industry leading technologies and establishing a global low-cost manufacturing footprint, which makes our business synergistic with IntriCon’s strategic growth objectives,” said Steve Wiesner, chief executive officer of EMS. “We look forward to joining IntriCon at this pivotal time and to becoming a material contributor to the opportunity ahead.”IntriCon expects the acquisition to be accretive to revenue and earnings in 2020.About IntriCon Corporation Headquartered in Arden Hills, Minn., IntriCon Corporation designs, develops and manufactures miniature interventional, implantable and body-worn medical devices. These advanced products help medical, healthcare and professional communications companies meet the rising demand for smaller, more intelligent and better connected devices. IntriCon has facilities in the United States, Asia and Europe. The company’s common stock trades under the symbol “IIN” on the NASDAQ Global Market. For more information about IntriCon, visit www.intricon.com.About Emerald Medical ServicesFounded in 2011, Emerald Medical Services Pte Ltd (“EMS”) is a Singaporean limited liability company that provides joint development manufacturing services to medical device original equipment manufacturers (“OEMs”) with a particular focus on advanced complex catheters for cardiology, peripheral vascular, neurology, radiology and pulmonology applications.Investor Relations Contact:Leigh Salvo(415) 937-5404investorrelations@intricon.com

Acquisition

100 Deals associated with EMS SA (Brazil)

Login to view more data

100 Translational Medicine associated with EMS SA (Brazil)

Login to view more data

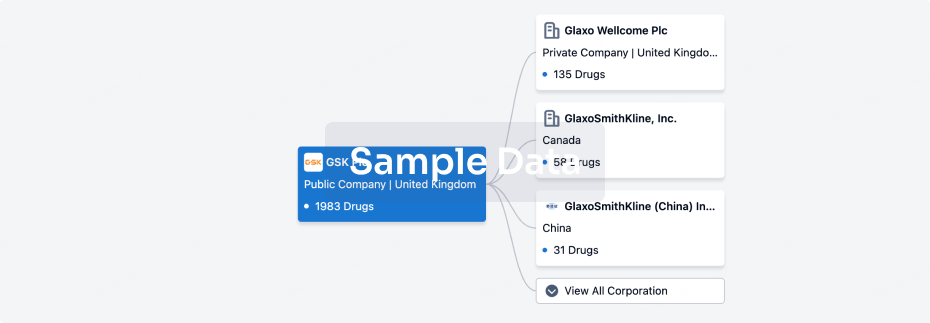

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 05 Mar 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Phase 3 Clinical

9

21

Other

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

DEH-113 | Primary dysmenorrhea More | Phase 3 |

Madalena association | Diabetes Mellitus, Type 2 More | Phase 3 |

LID-104 | Diabetes Mellitus, Type 2 More | Phase 3 |

OMA-102 | Baldness, Female Pattern More | Phase 3 |

Berlim 25/20 association | Diabetes Mellitus, Type 2 More | Phase 3 |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

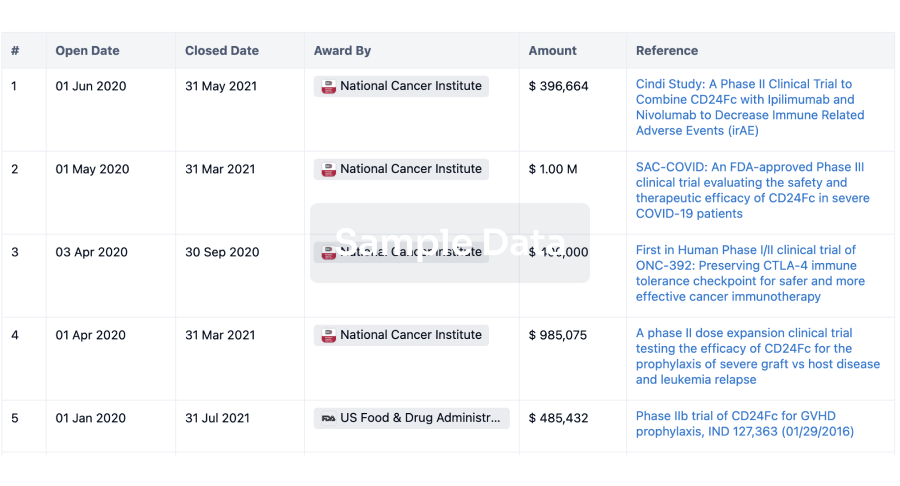

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free