Last update 01 Nov 2024

Fritz Haber Institute of The Max Planck Society

Last update 01 Nov 2024

Overview

Tags

Congenital Disorders

Immune System Diseases

Respiratory Diseases

Nanobody

Disease domain score

A glimpse into the focused therapeutic areas

No Data

Technology Platform

Most used technologies in drug development

No Data

Targets

Most frequently developed targets

No Data

| Disease Domain | Count |

|---|---|

| Immune System Diseases | 1 |

| Top 5 Drug Type | Count |

|---|---|

| Nanobody | 1 |

Related

1

Drugs associated with Fritz Haber Institute of The Max Planck SocietyTarget- |

Mechanism- |

Originator Org. |

Inactive Indication- |

Drug Highest PhaseDiscovery |

First Approval Ctry. / Loc.- |

First Approval Date- |

100 Clinical Results associated with Fritz Haber Institute of The Max Planck Society

Login to view more data

0 Patents (Medical) associated with Fritz Haber Institute of The Max Planck Society

Login to view more data

5,709

Literatures (Medical) associated with Fritz Haber Institute of The Max Planck Society09 Oct 2024·Nano Letters

Understanding the Growth of Electrodeposited PtNi Nanoparticle Films Using Correlated In Situ Liquid Cell Transmission Electron Microscopy and Synchrotron Radiation

Article

Author: Sobczak, Kamil ; Depciuch, Joanna ; Pawlyta, Mirosława ; Tarnawski, Tomasz Roman ; De Marco, Maria Letizia ; Parlinska-Wojtan, Magdalena ; Chee, See Wee ; Matlak, Krzysztof ; Schaeublin, Robin E.

09 Oct 2024·Journal of the American Chemical Society

Atomic Insights into the Competitive Edge of Nanosheets Splitting Water

Article

Author: Jones, Travis E. ; Lotsch, Bettina V. ; Tarasov, Andrey ; Falling, Lorenz J. ; Chuang, Cheng-Hao ; Teschner, Detre ; Terban, Maxwell W. ; Weber, Daniel ; Velasco-Vélez, Juan-Jesús ; Dinnebier, Robert ; Götsch, Thomas ; Girgsdies, Frank ; Schlögl, Robert ; Laha, Sourav ; Lunkenbein, Thomas ; Bette, Sebastian ; Knop-Gericke, Axel ; Mom, Rik ; Jang, Woosun

02 Oct 2024·Nano Letters

Coherent Modulation of Two-Dimensional Moiré States with On-Chip THz Waves

Article

Author: Maehrlein, Sebastian F. ; Dean, Cory R. ; Zhu, Xiaoyang ; Watanabe, Kenji ; Guo, Yinjie ; Hone, James C. ; Taniguchi, Takashi ; Arsenault, Eric A. ; Gamelin, Daniel ; Wang, Xi ; Yang, Birui ; Park, Heonjoon ; Li, Yiliu ; Xu, Xiaodong

6

News (Medical) associated with Fritz Haber Institute of The Max Planck Society31 Aug 2023

A team of researchers addressed the question: what happens to a Ga-promoted Cu surface under reaction conditions required for the synthesis of methanol? They found complex structural transformations of this bimetallic catalyst that might change the common view on the catalytically active surface structure.

A team of researchers from the Department of Interface Science at the Fritz Haber Institute of the Max Planck Society addressed the question: what happens to a Ga-promoted Cu surface under reaction conditions required for the synthesis of methanol? They found complex structural transformations of this bimetallic catalyst that might change the common view on the catalytically active surface structure.

Hydrogenation of CO2 to methanol occurs with high efficiency on famous Cu/ZnO/Al2O3 catalysts at high pressures, i.e. 50 -- 100 bar. However, this synthesis does not only bring along safety risks and a high energy consumption, but also limits the CO2 concentration in the gas feed in order to maintain high selectivity. Therefore, a new class of catalysts for low pressure methanol synthesis is highly desirable, also for future development of small-scale devices using solar-generated hydrogen at ambient pressure.

It has recently been discovered that intermetallic compounds and alloys containing Ga show good catalytic performance even at atmospheric pressures. However, the promotional role of Ga in these catalysts is still poorly understood, primarily because of the lack of information about the surface structures of the catalysts. In this respect, studies using surface-sensitive techniques applied to well-defined model catalysts under reaction conditions can provide key information that will aid our understanding of the dynamic nature of the active sites, reaction intermediates, and ultimately the reaction mechanism.

A team of researchers from the Department of Interface Science at the Fritz Haber Institute took advantage of laboratory-based Near Ambient Pressure X-ray Photoelectron Spectroscopy (NAP-XPS) and Scanning Tunneling Microscopy (NAP-STM), to monitor in situ the structural and chemical evolution of Ga-Cu bimetallic surfaces in the CO2 hydrogenation reaction. They observed temperature- and pressure-dependent de-alloying of the bimetallic surface resulting in Ga-oxide islands embedded into the Cu surface. Although the oxide phase showed a stoichiometry close to Ga2O3, i.e., the most stable Ga-oxide, it actually forms an ultrathin layer. The promotional effect of metals like Ga, which are prone to oxidation, is often discussed within structure models where a bulk oxide is placed on top of the metal surface and the corresponding reaction mechanism involves spillover of intermediate species at the interface. The present study clearly demonstrated that: (i) Ga-oxide is embedded into the metal surface; and (ii) the Ga-oxide islands are ultrathin, most likely of "monolayer" thickness. The reaction -induced formation of ultrathin Ga-oxide layer on metal surfaces is also anticipated for Ga-containing intermetallic compounds. Importantly, such two-dimensional oxide films are very different from their bulk counterparts in terms of structure and reactivity. Therefore, the GaOx/Cu interface formed under CO2 hydrogenation reaction conditions may expose catalytically active sites never considered for this reaction before. Such information would be impossible to obtain using bulk-sensitive techniques commonly employed for the characterization of powder catalysts.

The results of this study, carried out within the framework of the CATLAB project and also supported by the Alexander von Humboldt Foundation, which was just published in Nature Communications, shed light on the complex surface structure of Ga-containing catalytic systems. Such insight on working catalysts is only possible to obtain using state-of-the-art experimental techniques under reaction conditions. Only by establishing the atomic structure of the Ga-oxide layer(s) and its interface to the transition metal under working conditions can one bring insight into the reaction mechanism of this methanol synthesis catalyst.

05 May 2023

Photovoltaics, the conversion of light to electricity, is a key technology for sustainable energy. Since the days of Max Planck and Albert Einstein, we know that light as well as electricity are quantized, meaning they come in tiny packets called photons and electrons. In a solar cell, the energy of a single photon is transferred to a single electron of the material, but no more than one. Only a few molecular materials like pentacene are an exception, where one photon is converted to two electrons instead. This excitation doubling, which is called exciton fission, could be extremely useful for high-efficiency photovoltaics, specifically to upgrade the dominant technology based on silicon. Researchers have now deciphered the first step of this process by recording an ultrafast movie of the photon-to-electricity conversion process, resolving a decades-old debate about the mechanism of the process.

Photovoltaics, the conversion of light to electricity, is a key technology for sustainable energy. Since the days of Max Planck and Albert Einstein, we know that light as well as electricity are quantized, meaning they come in tiny packets called photons and electrons. In a solar cell, the energy of a single photon is transferred to a single electron of the material, but no more than one. Only a few molecular materials like pentacene are an exception, where one photon is converted to two electrons instead.

"When pentacene is excited by light, the electrons in the material rapidly react," explains Prof. Ralph Ernstorfer, a senior author of the study. "It was an open and very disputed question whether a photon excites two electrons directly or initially one electron, which subsequently shares its energy with another electron."

To unravel this mystery the researchers used time- and angle-resolved photoemission spectroscopy, a cutting-edge technique to observe the dynamics of electrons on the femtosecond time scale, which is a billionth of a millionth of a second. This ultrafast electron movie camera enabled them to capture images of the fleeting excited electrons for the first time.

"Seeing these electrons was crucial to decipher the process," says Alexander Neef, from the Fritz Haber Institute and the first author of the study. "An excited electron not only has a specific energy but also moves in distinct patterns, which are called orbitals. It is much easier to tell the electron apart if we can see their orbital shapes and how these change over time."

With the images from the ultrafast electron movie at hand, the researchers decomposed the dynamics of the excited electrons for the first time based on their orbital characteristics. "We can now say with certainty that only one electron is excited directly and identified the mechanism of the excitation-doubling process," adds Alexander Neef.

Knowing the mechanism of exciton fission is essential to using it for photovoltaic applications. A silicon solar cell enhanced with an excitation-doubling material could boost the solar-to-electricity efficiency by one-third. Such an advance could have enormous impacts since solar energy will be the dominant power source of the future. Already today large investments are flowing into the construction of these third-generation solar cells.

PROTACs

06 Apr 2023

A research team has discovered how catalysts and many other nanoplatelets can be produced in an environmentally friendly way from readily available materials and in sufficient quantities.

Hydrogen is considered an environmentally friendly alternative to conventional fossil fuels. Until now, expensive and rare substances such as platinum have been needed for its catalytic production, for example via electrolytic water splitting. More readily available catalysts could make the production of large quantities possible in the future. The research teams of Helmut Cölfen (Physical Chemistry) and Peter Nielaba (Statistical and Computational Physics) at the University of Konstanz have developed a general method to produce two-dimensional nanoparticles from readily accessible materials, together with researchers from the Ocean University of China, Qingdao (China) and the Fritz Haber Institute of the Max Planck Society, Berlin (Germany). Two-dimensional nanoparticles have a high catalytic potential, which is why this synthetic route is suitable for producing particularly active catalysts.

The corresponding synthesis process is carried out in a simple aqueous solution. No toxic additives or particularly high temperatures, which are energetically unfavourable, are required. The process is controlled by simply varying the concentration of the components and by temperature regulation. The research team succeeded in shaping more than 30 different compounds into two-dimensional forms using this method, which has been described now for the first time in the scientific journal Nature Synthesis.

The advantage of two-dimensional nanoparticles

Two-dimensional (2D) nanoparticles have a particularly large number of surface atoms, which have different properties than atoms within a particle. The bonds of the surface atoms are non-saturated because the surface lacks the immediate neighbouring atoms to which bonds are formed inside the particle. This leads to surface or interfacial tension. Since this non-saturated state is quite energy consuming for the overall system, nanoparticles try to cluster together to saturate the bonds and minimize the surface area.

However, if the surface bonds remain unsaturated, this results in increased chemical reactivity. The number of unsaturated bonds is particularly high in two-dimensional nanoparticles because they have unsaturated bonds not only at the top and bottom, but also at the sides and edges. This makes them particularly interesting for catalysis, which plays a major role in chemistry. However, the required nanocrystals are difficult to fabricate because of the unfavourable energy state at the surface.

Two-dimensional nanoparticles are anisotropic, and their properties depend on the orientation of their building blocks. The crystal lattice of the particles is decisive for their growth direction. If the nanoparticles have a layered crystal lattice as in clay, the particles grow two-dimensionally. However, materials that are favourable for catalysis rarely adopt the two-dimensional shape on their own. If the crystal lattice dictates that the crystal grows rapidly along two crystal axes, two-dimensional nanoparticles can be easily synthesized. Then, only a few molecular building blocks are needed in the solution to grow the nanoparticles two-dimensionally. If the crystals grow in other directions just as fast or only slightly slower, the crystals take on a three-dimensional shape.

How nanoparticles grow two-dimensionally

The research team has discovered how the concentration of molecular building blocks in the solution can be used to manipulate this process: If the concentration of building blocks is increased, the principle of "what grows fast also consumes more material" comes into play: The distance between the fast-growing and the slower growing crystal axes increases, resulting in two-dimensional particles.

The method of increasing the building block concentration does not work if the growth rate along different relevant crystal axes is approximately the same. In this case, the researchers use another parameter. The growth rate of crystal surfaces depends exponentially on temperature. If the temperature of the solution is changed by even a few degrees, the difference in the growth rate between the slow and fast-growing crystal faces will increase. As a result, the nanoparticles grow in two dimensions.

Method works for over 30 elements of the periodic table

This general procedure works for many materials. In the periodic table, the German-Chinese research team was able to identify metals in many groups, more than 30 in total, which take the two-dimensional form as oxides or hydroxides, but also acids, sulfides, oxychlorides and phosphates. The advantage of this general approach, which has been described for the first time: In most cases, the materials are produced at room temperature in water -- without toxic solvents or high temperatures.

Moreover, the yield of catalytic materials is highly scalable. In the lab, the researchers are working on a multigram scale. To produce catalysts in large quantities using easily accessible substances, all that is needed is a sealed vessel -- instead of special apparatuses such as pressure vessels.

Experiments confirm theory

The experimental study also shows how theoretical knowledge can be put into practice. The experiments confirm theoretical simulations performed by Peter Nielaba's team in a joint project with the Cölfen team in the Collaborative Research Centre 1214 "Anisotropic Particles as Building Blocks: Tailoring Shape, Interactions and Structures" at the University of Konstanz. The physicist had already taken into account variations in the concentration of the components and the temperature. "The calculations and what we have found experimentally completely coincides," concludes Helmut Cölfen.

The synthesis process is carried out in a simple aqueous solution at room temperature. No toxic additives or particularly high temperatures are required.

100 Deals associated with Fritz Haber Institute of The Max Planck Society

Login to view more data

100 Translational Medicine associated with Fritz Haber Institute of The Max Planck Society

Login to view more data

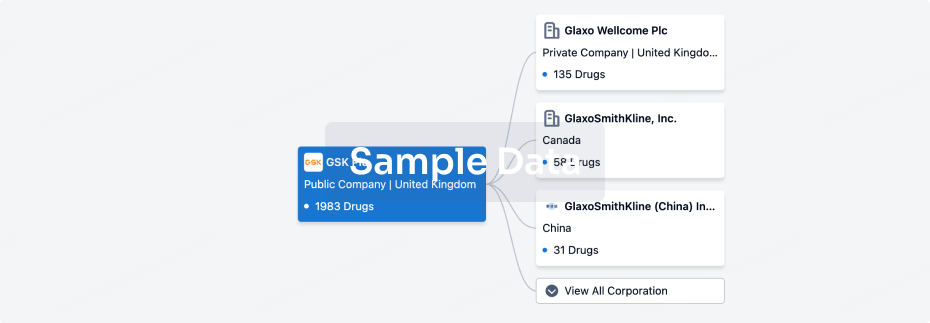

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 14 Nov 2024

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Discovery

1

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

VHH antibodies (BiondVax) | Asthma More | Discovery |

Login to view more data

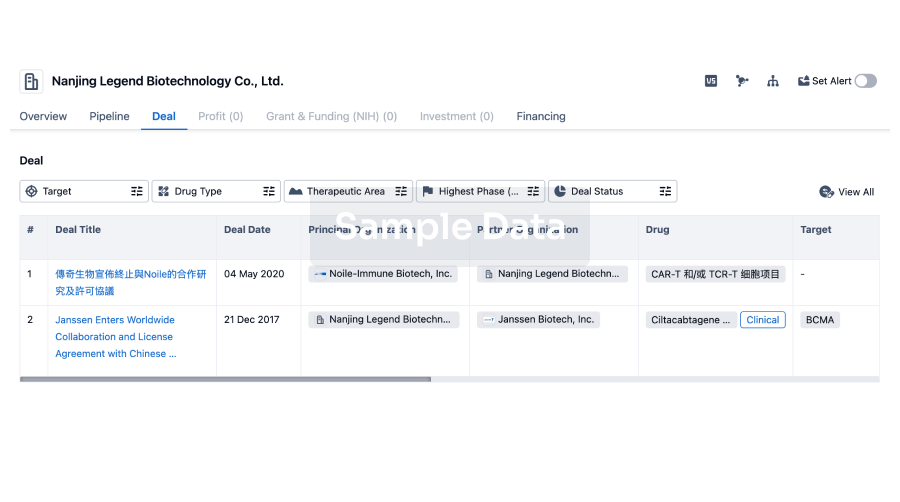

Deal

Boost your decision using our deal data.

login

or

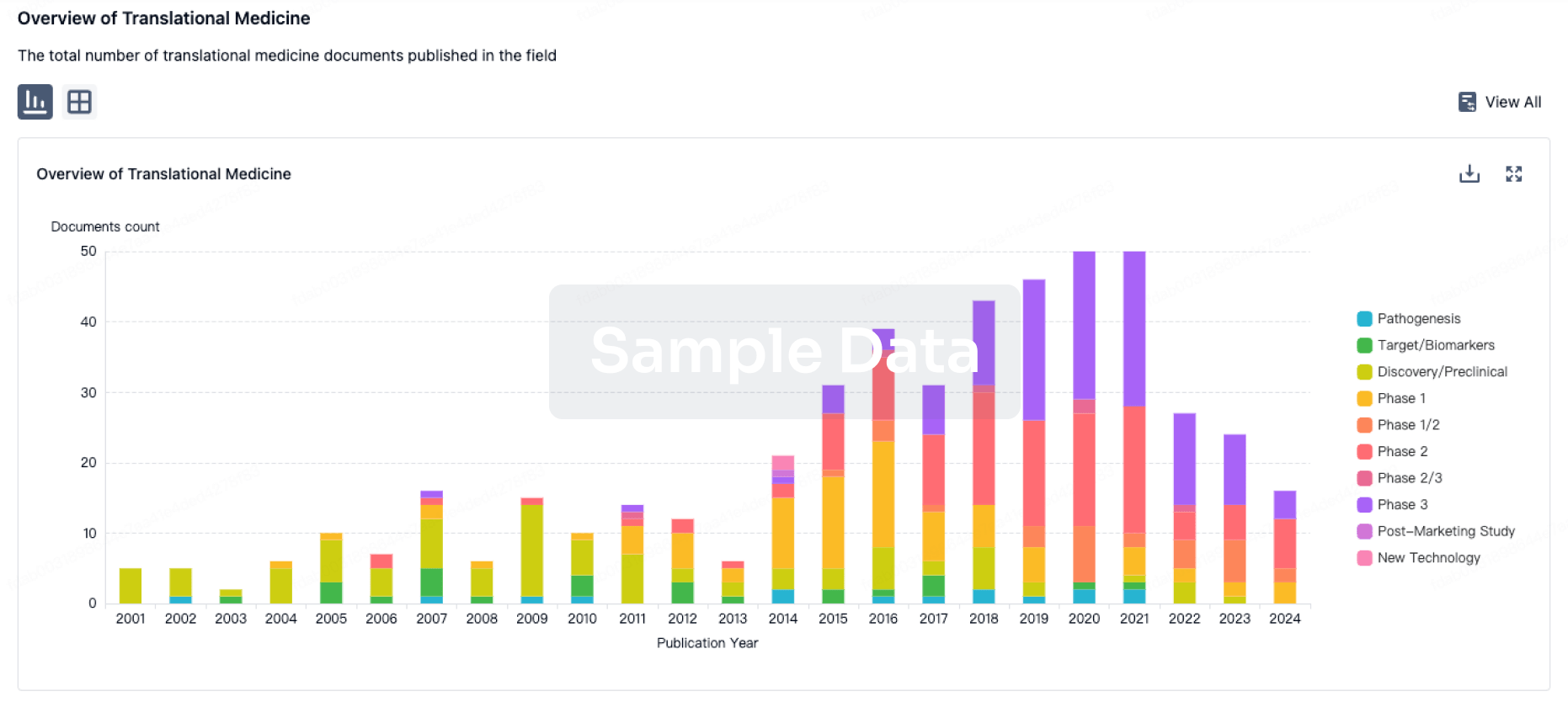

Translational Medicine

Boost your research with our translational medicine data.

login

or

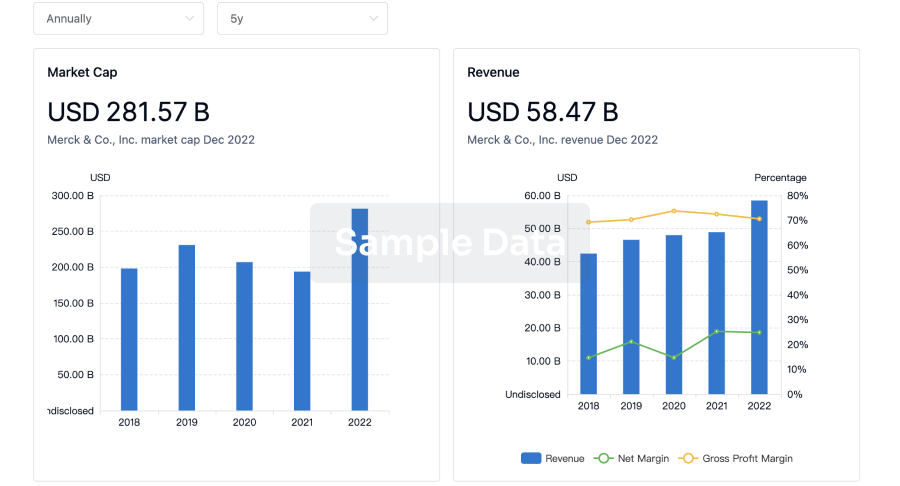

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

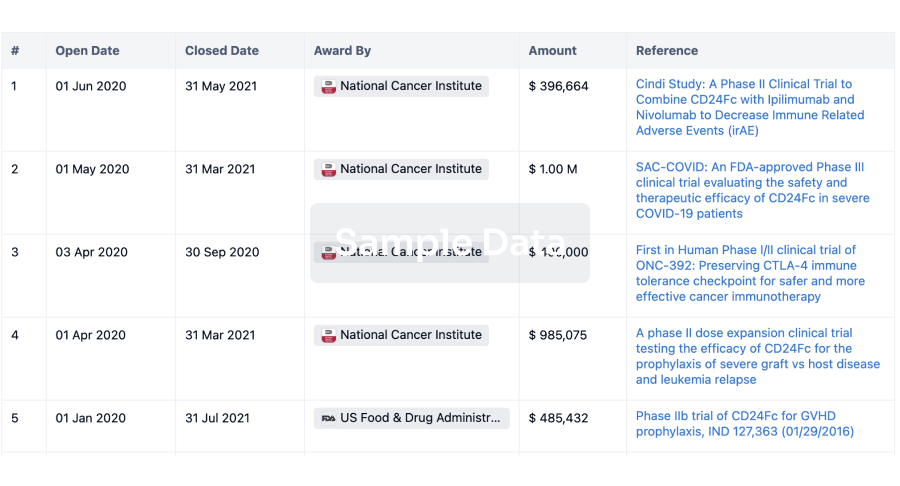

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

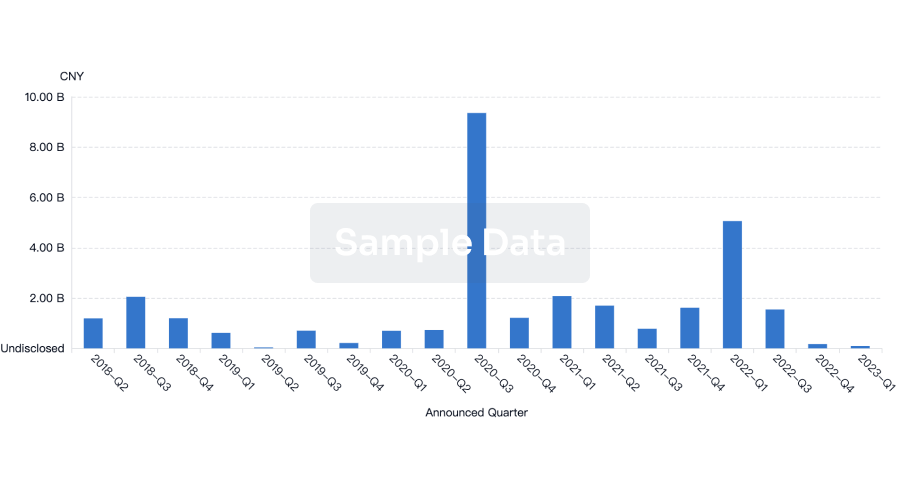

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

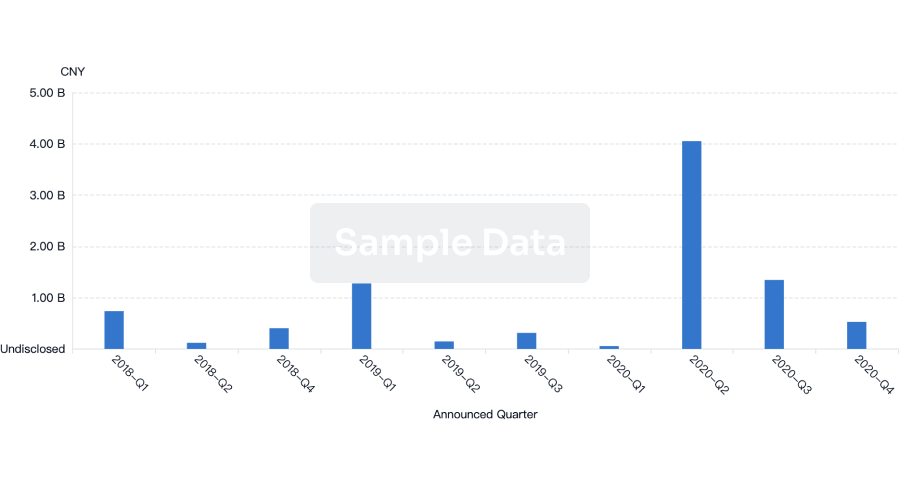

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

Chat with Hiro

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free