Request Demo

Last update 14 Aug 2025

Spirair, Inc.

Last update 14 Aug 2025

Overview

Related

3

Clinical Trials associated with Spirair, Inc.NCT07027267

A Prospective, Multi-Center, Open-Label Study to Evaluate the Safety and Effectiveness of TurbAlign™ to Achieve Middle Turbinate Medialization After Functional Endoscopic Sinus Surgery (FESS) (GAIA)

A study of a bioabsorbable implant to separate the middle turbinate from the lateral nasal wall associated with nasal/sinus surgery

Start Date05 Aug 2025 |

Sponsor / Collaborator |

NCT06163404

A Prospective, Multi-Center, Open-Label Study to Evaluate the Safety and Effectiveness of the Spirair Implant for Correction of Cartilaginous Nasal Septal Deviation

Pilot study of bioabsorbable implant and delivery device for correction of septal deviation.

Start Date01 Nov 2023 |

Sponsor / Collaborator |

NCT05967169

Early Feasibility Study of Bioabsorbable Polydioxanone Implant and Delivery Device for Correction of Cartilaginous Septal Deviation

Early feasibility study of bioabsorbable implant and delivery device for correction of septal deviation

Start Date25 May 2022 |

Sponsor / Collaborator |

100 Clinical Results associated with Spirair, Inc.

Login to view more data

0 Patents (Medical) associated with Spirair, Inc.

Login to view more data

5

News (Medical) associated with Spirair, Inc.12 Jun 2025

SOUTH SAN FRANCISCO, Calif.--(BUSINESS WIRE)--Spirair, Inc., an early-stage company developing minimally invasive solutions to help ENTs improve patient care, today announced the publication of the first clinical study evaluating its SeptAlign™ implant. The positive 12-month outcomes demonstrate the safety and efficacy of this novel bioabsorbable device, which offers a cartilage-sparing approach to traditional septoplasty for the treatment of nasal septal deviation (NSD).

NSD is a leading cause of nasal airway obstruction, impacting breathing and quality of life for millions. Unlike standard septoplasty, which often requires cartilage removal, SeptAlign supports a tissue-preserving technique that can be used to address cartilaginous septal deviations, including difficult-to-treat anterior deviations.

In the Zephyr Study, a prospective feasibility study of 14 patients with mobile cartilaginous NSD, the SeptAlign implant was inserted alongside inferior turbinate reduction. Results at 12 months post-procedure demonstrated:

71.8% median improvement in NOSE (Nasal Obstruction Symptom Evaluation) scores (from 58 to 15; p=0.001 )

60.3% median improvement in SNOT-22 (Sinonasal Outcome Test) scores (from 37 to 8; p=0.004 )

Rapid improvement, with 92.9% of patients showing NOSE score response and 78.6% showing SNOT-22 response within the first month

“These results show great promise for a minimally invasive, bioabsorbable implant to offer lasting symptom relief while preserving the structural integrity of the nasal cartilage,” said Greg Davis, M.D., MPH of Proliance Surgeons and lead author of the study.

“I was pleased to see the excellent safety and tolerability profile of the SeptAlign implant. This innovation could redefine how we approach treatment for nasal obstruction caused by septal deviation,” said Steven Davis, M.D. of the Breathe Clear Institute and co-principal investigator of the study.

The study authors conclude that early findings support the safety, tolerability, and efficacy of the SeptAlign implant. These results support larger, prospective, open-label studies and continued clinical use.

About SeptAlign™

SeptAlign is a proprietary bioabsorbable implant developed to correct cartilaginous nasal septal deviations. The implant is inserted in the cartilage near the front of the nose and holds the straightened septum under tension, dissolving within six months. Its innovative design allows ENT specialists to realign and support the nasal septum, including challenging anterior caudal deviations, while preserving cartilage. SeptAlign can be used in any site of service as part of standard septoplasty techniques, including the office, the operating room (OR), and the ambulatory surgery center (ASC). The SeptAlign System received FDA clearance in 2024 and is commercially available in the United States. Visit septalign.com for more information.

About Spirair®

Spirair, Inc. is an early-stage company pioneering minimally invasive solutions that help ENTs advance care for their patients by providing strong outcomes and a better patient experience. Spirair is committed to developing new therapies that can easily integrate in any ENT’s treatment algorithms so they can help more of their patients breathe better. The company originated from the Stanford Biodesign Innovation Fellowship and Fogarty Innovation - renowned medtech incubators that train innovators to identify unmet healthcare needs, develop novel solutions, and bring them to clinical use. Visit spirair.com for more information.

Clinical Result

08 Jul 2024

A new therapy for nasal septal deviation builds on decades of polydioxanone research and development.

By James Kintzing and Dr. Brandon McCutcheon, Spirair

When we founded Spirair and began developing SeptAlign — a novel therapy designed to mechanically correct nasal septal deviation (NSD) — we knew we needed to find a material that could hold the nasal septum under tension long enough for cartilage remodeling but also resorb within an appropriate time frame.

We ultimately chose polydioxanone (PDO), which has been widely used for decades for medtech applications spanning from plastic surgery to orthopedics to cardiology. As we refined SeptAlign and prepared to bring it through clinical research and regulatory review, PDO became a clear choice over many other materials that bring healthcare innovation to life.

The challenge

As co-fellows in the Stanford Biodesign Innovation Fellowship, we spent months in clinical settings observing processes and patient care to identify a list of areas with significant unmet needs. We were drawn to the ear, nose and throat (ENT) specialty, where we observed ENT physicians increasingly using minimally invasive technologies with the potential to broaden the reach of patient care and often enable treatment in the physician’s office rather than the OR.

We discovered that NSD was one of the last areas in the space that did not have a minimally invasive treatment approach, despite being one of the most common problems seen by ENTs.

NSD is one of the most common causes of nasal airway obstruction (NAO), a condition that makes it difficult to breathe through the nose. Nasal airflow is massively impacted by the diameter of the airway. Even a very small deviation in the anterior of the nose where airflow is most restricted can significantly impact nasal breathing. While most people have a deviated septum to some degree and may not require medical intervention, millions of people in the U.S. are symptomatic enough to seek ENT care annually. People with this condition may experience difficulty breathing out of one or both nostrils, headaches, facial pain, nasal congestion, noisy breathing, nosebleeds, chronic sinusitis, snoring and dry mouth.

Traditional septoplasty or septorhinoplasty are the most common open surgical options for NSD. While effective, these procedures are invasive and can require significant downtime, with some patients requiring two weeks or more to recover.

These learnings presented us with an unmet need among people living with NSD and NAO and an opportunity to develop a solution.

Finding the right absorbable polymer

We started imagining how we could effectively correct NSD in a much less invasive way than existing surgical procedures. We thought about this similarly to how a gardener trains a tree or flowers to grow vertically, providing the needed structural support until they can grow upright and flourish on their own. Unlike training trees and flowers, mechanically correcting NSD requires more careful material selection.

We knew we needed a material with appropriate tensile strength, biocompatibility, and a resorption time matching the time needed for the cartilage to heal. It was also important to find a well-characterized material with well-studied mechanism of predictable degradation. The goal with absorbable polymers is to have resorption time match the use case, which requires a careful balance. A mismatch between absorption time and the time needed to heal could increase the risk of complications in this type of procedure.

PLLA (poly-L-lactic acid) and PDLA (poly-D-lactic acid) copolymers have been used in other ENT applications such as lateral wall implants, which support the wall of the nose to prevent lateral wall collapse during breathing. These materials are effective in certain use cases, but we knew they would resorb too slowly for our purposes.

Similarly, poly(DL-lactide-co-glycolide) (PLGA) copolymers have been used successfully in other ENT applications including sinus implants, which are inserted into the sinus opening to maintain patency after sinus surgery. Again, PLGA can be effective in these applications, but we knew that it would resorb too quickly to be an effective material for SeptAlign.

Chosing polydioxanone for a bioabsorbable implant

After reviewing other materials used in similar applications, we landed on our “Goldilocks” solution and selected polydioxanone (PDO) as the material that would make up SeptAlign’s bioabsorbable implant.

PDO maintains sufficient tensile strength for at least six to 10 weeks, which is also the time required for cartilage remodeling. It also fully resorbs within six months, making it well suited for mechanical correction of NSD.

This material has been used in other applications outside of ENT for decades, including orthopedics, plastic surgery and cardiology. These applications have shown PDO’s safety and efficacy, and we knew we could build on its decades of success by using it in a new way with NSD correction.

Our early clinical research demonstrated that the cartilage can maintain its new shape after being held under tension by absorbable implants. When compared on a weight basis to other polymers commonly used in ENT such as poly(lactic acid) (PLA) and poly(glycolic acid) (PGA), PDO degradation products are less acidic, which could cause less of an inflammatory reaction during resorption.

Looking ahead

Innovation can often be catalyzed by reimagining the familiar. As we look to the future, innovation at Spirair will continue to draw inspiration from everyday materials, methods, and mechanism. SeptAlign received FDA clearance in March 2024, and we are beginning a limited rollout before larger-scale commercialization later this year.

We are looking forward to sharing additional data from our ongoing clinical research and updates on SeptAlign as we bring it to more physicians and patients across the country.

James Kintzing, Spirair co-founder and chief technology officer, is a bioengineer, entrepreneur, and inventor of technologies spanning applications from polymer chemistry to cancer therapeutics to medical devices. He completed the Stanford Biodesign and Innovation Fellowship in 2020.

Dr. Brandon McCutcheon, Spirair co-founder and chief medical officer, is a neurosurgeon, inventor, medical device entrepreneur, and author on over 40 peer reviewed publications. He completed the Stanford Biodesign and Innovation Fellowship in 2020.

How to submit a contribution to MDO

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.

09 Apr 2024

SeptAlign, which is the firm’s first product, is specifically engineered to assist in stabilising and correcting minor deviations in septal cartilage, achieved when sufficient healthy cartilage is available and effectively mobilised through standard septoplasty techniques

FDA approves Spirair’s SeptAlign system in nasal septal deviation treatment. (Credit: Sasin Tipchai from Pixabay)

Spirair has secured 510(k) clearance for its SeptAlign system from the US Food and Drug Administration (FDA) for its use in the mechanical correction of nasal septal deviation (NSD).

Based in the US, Spirair is an early-stage company engaged in developing minimally invasive solutions to help ear, nose, and throat (ENT) specialists in advancing care for their patients.

SeptAlign, which is Spirair’s first product, is specifically engineered to assist in stabilising and correcting minor deviations in septal cartilage. This is achieved when sufficient healthy cartilage is available and effectively mobilised through standard septoplasty techniques.

The approval of the SeptAlign system in nasal septal deviation follows the FDA clearance of the SeptAlign bioabsorbable implant in August 2023. This marks the final step in the FDA clearance process for the SeptAlign System.

Nasal septal deviation is a prevalent cause of nasal airway obstruction (NAO), leading to difficulty in breathing through the nose.

Current treatment options for symptomatic nasal septal deviation are limited to over-the-counter medications for symptom relief. Invasive surgical procedures like traditional septoplasty are also utilised to address the underlying structural issues causing these symptoms.

Spirair CEO Benjamin Bishop said: “Demand for minimally invasive treatment options has been steadily rising across healthcare in recent years, but there have been few such options for people suffering from symptomatic NSD.

“SeptAlign is a minimally invasive treatment that can be safely and conveniently performed under local anesthesia and enables ENTs to expand their treatment options for more patients.”

SeptAlign has undergone clinical validation for correcting minor cartilaginous septal deviation. Treatment with it can be carried out at various service locations, including the office, operating room (OR), and/or ambulatory surgery center (ASC), as part of standard septoplasty procedures.

The bioabsorbable SeptAlign implant is positioned near the anterior nasal region, applying continuous tension to uphold the straightened septum, eventually dissolving within a six-month period.

SeptAlign is presently under investigation in two US clinical trials approved by institutional review boards (IRBs) as nonsignificant risk (NSR).

Having obtained clearance for the SeptAlign system, Spirair intends to commence a Series B fundraising round and initiate the commercialisation phase.

Drug Approval

100 Deals associated with Spirair, Inc.

Login to view more data

100 Translational Medicine associated with Spirair, Inc.

Login to view more data

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 05 Mar 2026

No data posted

Login to keep update

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

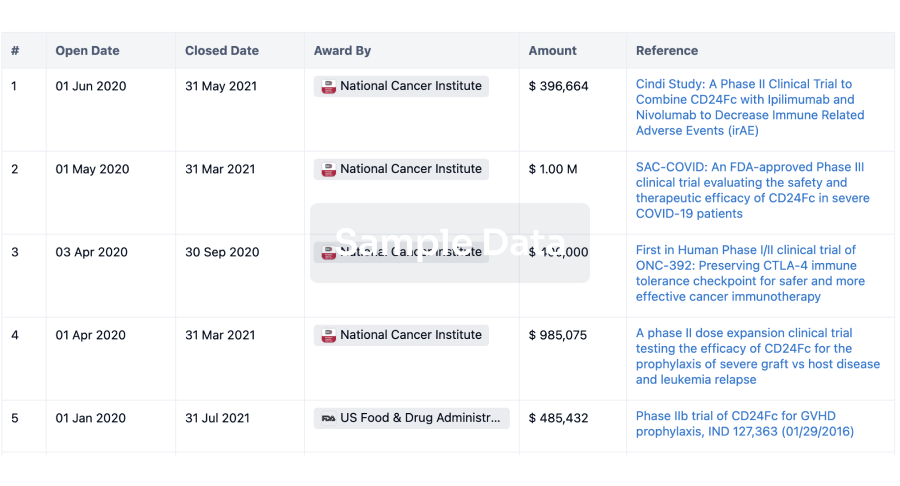

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free