Request Demo

Last update 08 May 2025

Universitas Udayana

Last update 08 May 2025

Overview

Related

32

Clinical Trials associated with Universitas UdayanaNCT06750627

Efficacy of Continuous Erector Spinae Plane Block to Reduce Postoperative Pain in Patients Undergoing Unilateral Thoracotomy

The goal of this clinical trial is to learn if continuous Erector Spinae Plane Block (ESPB) reduces postoperative pain in patients undergoing unilateral thoracotomy. It will also evaluate the safety and effectiveness of continuous ESPB. The total participants needed will be 30 persons. The main questions it aims to answer are:

* Does continuous ESPB lower the intensity of postoperative pain compared to multimodal intravenous analgesia?

* Does continuous ESPB increase the time to first analgesic request?

* Does continuous ESPB reduce the amount of intravenous opioids required in the first 48 hours after surgery?

* Does continuous ESPB improve the overall recovery quality within 48 hours post-surgery?

Participants will:

* Receive continuous ESPB or multimodal intravenous analgesia after the surgery.

* Undergo routine pain assessments, and recovery evaluations using tools like the Visual Analogue Scale (VAS) and Quality of Recovery-15 (QoR-15).

* Participate in follow-up visits for data collection on pain, opioid usage, and recovery quality.

* Does continuous ESPB lower the intensity of postoperative pain compared to multimodal intravenous analgesia?

* Does continuous ESPB increase the time to first analgesic request?

* Does continuous ESPB reduce the amount of intravenous opioids required in the first 48 hours after surgery?

* Does continuous ESPB improve the overall recovery quality within 48 hours post-surgery?

Participants will:

* Receive continuous ESPB or multimodal intravenous analgesia after the surgery.

* Undergo routine pain assessments, and recovery evaluations using tools like the Visual Analogue Scale (VAS) and Quality of Recovery-15 (QoR-15).

* Participate in follow-up visits for data collection on pain, opioid usage, and recovery quality.

Start Date01 Jan 2025 |

Sponsor / Collaborator |

NCT06784258

Comparison of Inflammatory Factors, Pain Scale, and Postoperative Recovery Quality (QOR - 15) in Patients Undergoing Colorectal Cancer Surgery with Conventional General Anesthesia Techniques Compared to General Anesthesia Combined with Epidural Anesthesia At Prof. Ngoerah Hospital

Surgery can increase IL-6 cytokines, triggering inflammation and metastasis. The combination of general and epidural anesthesia has the potential to suppress IL-6, improve the tumor microenvironment, provide analgesia, and enhance postoperative recovery.

Objectives :To compare the effectiveness of postoperative analgesia quality in colorectal cancer patients receiving general anesthesia combined with epidural anesthesia.

Objectives :To compare the effectiveness of postoperative analgesia quality in colorectal cancer patients receiving general anesthesia combined with epidural anesthesia.

Start Date28 Dec 2024 |

Sponsor / Collaborator |

NCT06761092

Nebulized Dexmedetomidine to Reduce Post-Anesthesia Delirium of Sevoflurane in Preschool Children Undergoing Elective Surgery

Analyzing the effectiveness of nebulized dexmedetomidine 2 mcg/kg in reducing the incidence of post-anesthesia delirium in preschool children undergoing elective surgery with sevoflurane inhalation general anesthesia.

Researchers will compare nebulized Dexmedetomidine to a placebo (a look-alike substance that contains no drug) to see if the drug can reduce post anesthesia delirium incidence.

Researchers will compare nebulized Dexmedetomidine to a placebo (a look-alike substance that contains no drug) to see if the drug can reduce post anesthesia delirium incidence.

Start Date13 Dec 2024 |

Sponsor / Collaborator |

100 Clinical Results associated with Universitas Udayana

Login to view more data

0 Patents (Medical) associated with Universitas Udayana

Login to view more data

4,174

Literatures (Medical) associated with Universitas Udayana01 Jun 2025·Data in Brief

Balinese text-to-speech dataset as digital cultural heritage

Article

Author: Budiantari, Ni Made Julia ; Gunawan, I Made Suma ; Er, Ngurah Agus Sanjaya ; Octavia, Hana Christine ; Kadyanan, I Gusti Agung Gede Arya ; Putra, I Gede Ngurah Arya Wira ; Karyawati, Anak Agung Istri Ngurah Eka

01 Jun 2025·Case Studies in Chemical and Environmental Engineering

Green extraction method and microencapsulation of tannins from young coconut husks-based food waste using gelatin/nanofiber cellulose

Author: Arnata, I. Wayan ; Nitivattananon, Vilas ; Harsojuwono, Bambang Admadi ; Antares, Ardhinata ; Gunam, Ida Bagus Wayan ; Anggreni, Anak Agung Made Dewi ; Wrasiati, Luh Putu

01 May 2025·Home Health Care Management & Practice

Evaluating the Impact of Nurse-led Geriatric Homecare Interventions: A Systematic Review of Randomized Controlled Trials

Author: Wijanadi, M. Candra ; Januraga, Pande Putu ; Gautama, Made Satya Nugraha ; Pendet, Ni Made Diah Pusparini

1

News (Medical) associated with Universitas Udayana01 Dec 2021

ZURICH, SWITZERLAND / ACCESSWIRE / December 1, 2021 / Xlife Sciences (XLS DE) announced that Carl von Halem has been appointed as the Company's new Chief Financial Officer, effective as of today, 1 December 2021. Beat Kläui, who has been interim CFO since January 2019, will continue to serve Xlife Sciences as Head Accounting & Tax.

Carl von Halem has been Co-Founder and Chief Operating Officer of the Munich-based FinTech company CommneX since September 2016. CommneX's digital tendering and matchmaking platform brings together financial projects of municipalities, public corporations and municipal-related companies with financial partners such as banks, insurance companies and institutional investors. Previously, Carl worked, among others, as Senior Associate for the Berlin-based company SaEnergy Systems, which is active in the field of renewable energies. He holds a degree in economics from the Technical University of Berlin; as part of his studies, he completed an exchange semester at Udayana University Denpasar, Indonesia and a summer school in «Environmental Economics» at the London School of Economics.

Oliver R. Baumann, CEO of Xlife Sciences, commented: «With his international education, various stations in the fast-paced and challenging startup environment, the necessary leadership experience and his impressive work ethic, Carl brings the necessary skills to actively support our team and further advance the vision of Xlife Sciences. At the same time, we sincerely thank Beat for his valuable support in the last three years and are very happy that we are able to continue to rely on his wealth of experience.»

About Xlife Sciences

Xlife Sciences AG is a Swiss company with focus on investing in promising technologies in the life science industry. Xlife Sciences AG is building the bridge from research and development to healthcare markets by supporting researchers and entrepreneurs in positioning, structuring, developing and implementing their concepts. Together with industrial partners or universities, Xlife Sciences AG leads projects through the proof-of-concept phase after an invention disclosure or start-up. Subsequently, the firm focuses on out-licensing or selling the company, often with a combination of a strategic partnership. Xlife Sciences AG offers its investors direct access to the further development of innovative and future-oriented technologies at a very early stage. For more information, please visit:

Contact

For media inquiries: IRF Reputation AG, Valentin Handschin, handschin@irf-reputation.ch

For investor inquiries: Dennis Lennartz, Head Investor Relations, Xlife Sciences AG, Phone +41 44 385 84 60, dennis.lennartz@xlifesciences.ch

SOURCE: Xlife Sciences AG

View source version on accesswire.com:

100 Deals associated with Universitas Udayana

Login to view more data

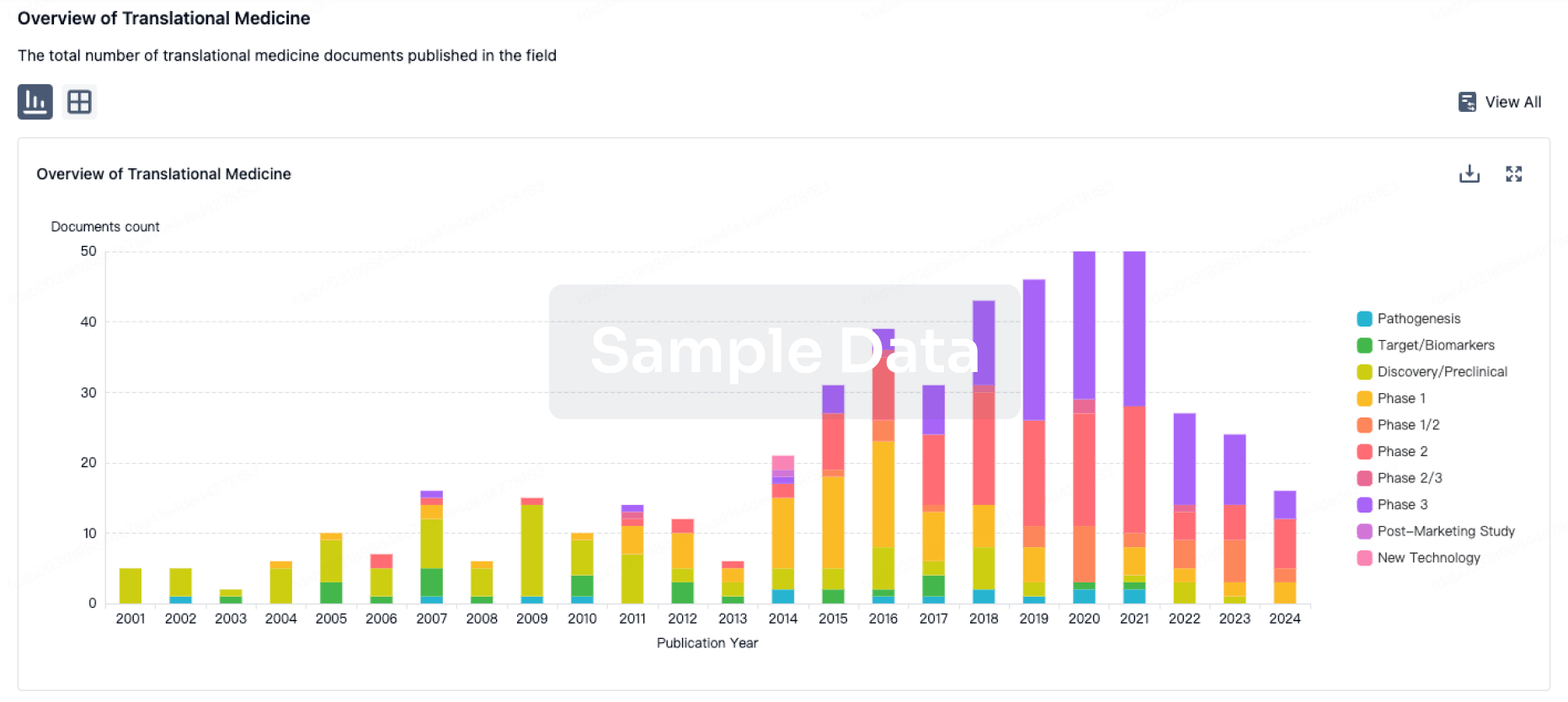

100 Translational Medicine associated with Universitas Udayana

Login to view more data

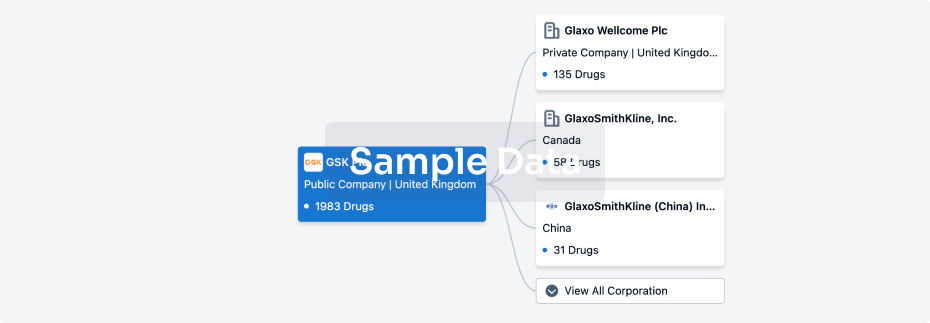

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 08 Dec 2025

No data posted

Login to keep update

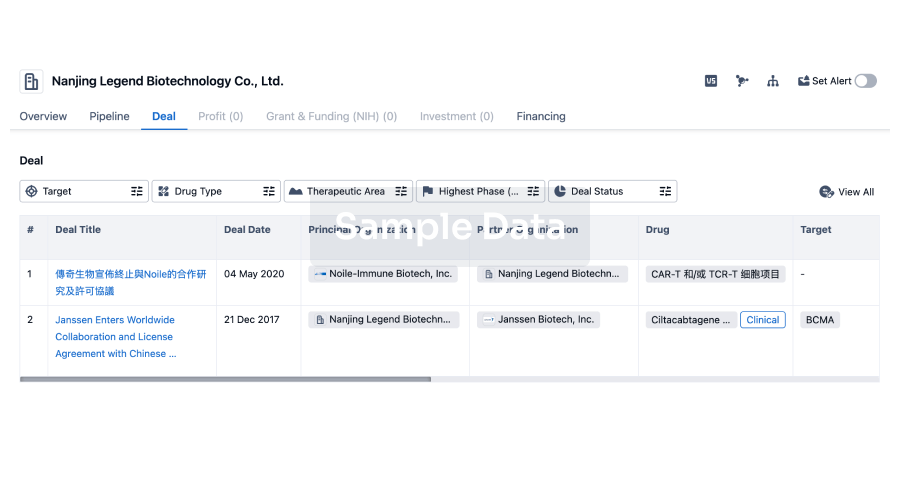

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

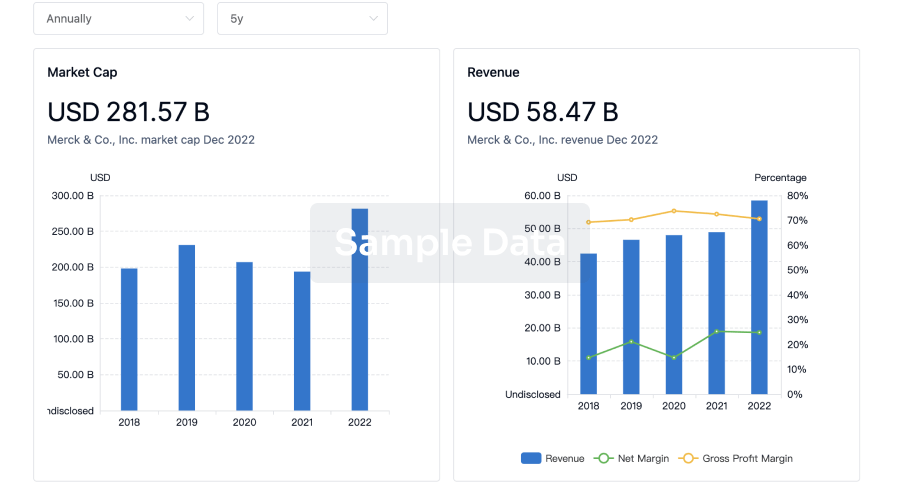

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

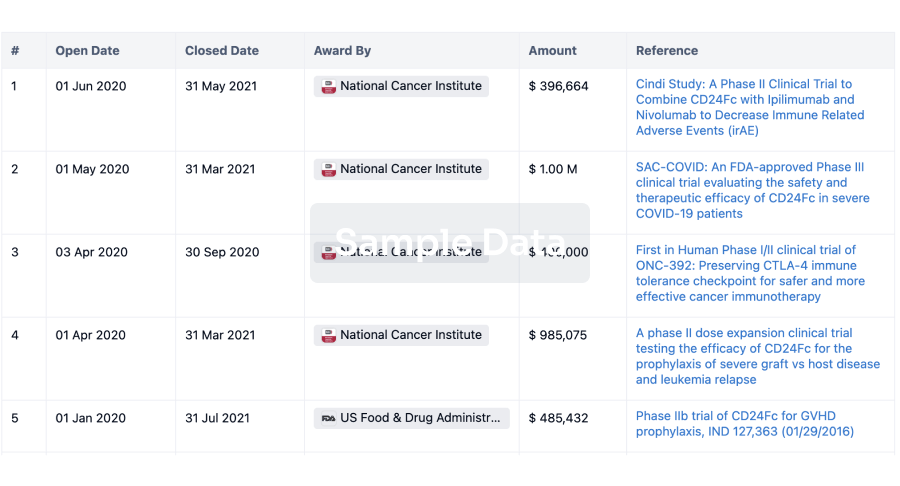

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

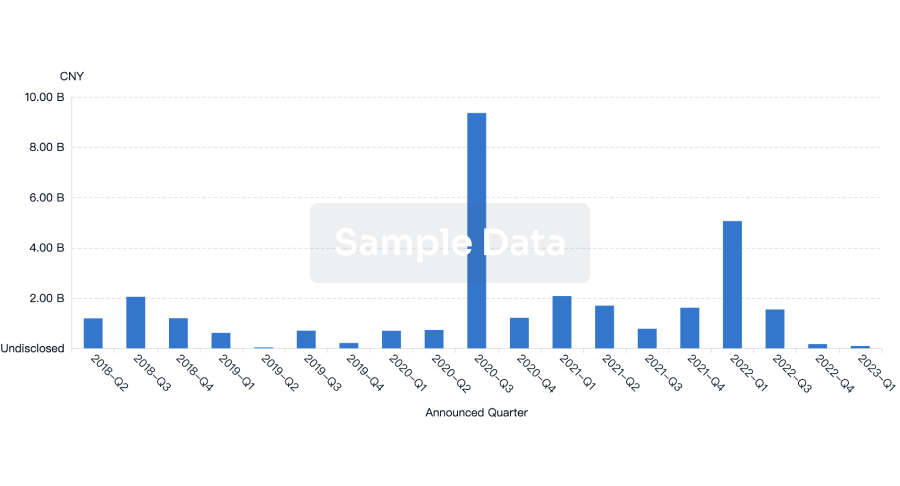

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

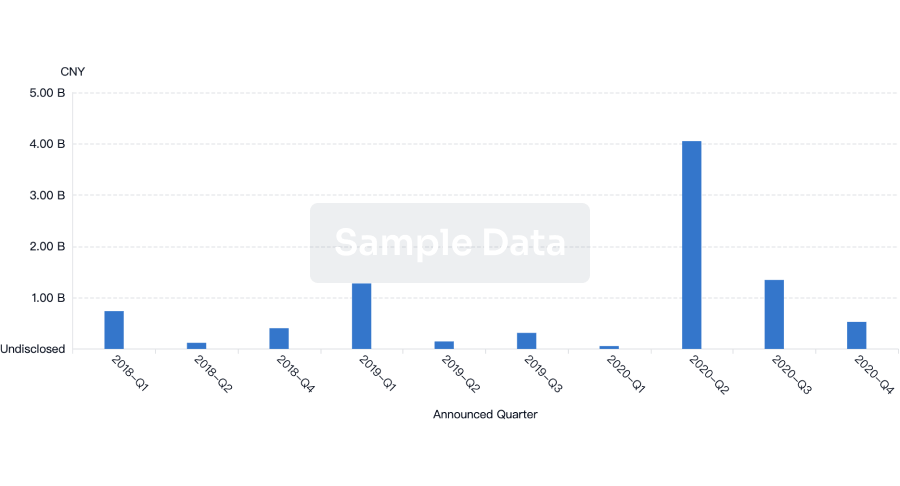

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free