Request Demo

Last update 02 Feb 2026

Twist Bioscience Corp.

Last update 02 Feb 2026

Overview

Tags

Neoplasms

Respiratory Diseases

Infectious Diseases

Monoclonal antibody

Biological products

Bispecific antibody

Disease domain score

A glimpse into the focused therapeutic areas

No Data

Technology Platform

Most used technologies in drug development

No Data

Targets

Most frequently developed targets

No Data

| Disease Domain | Count |

|---|---|

| Neoplasms | 7 |

| Infectious Diseases | 4 |

| Endocrinology and Metabolic Disease | 3 |

| Immune System Diseases | 1 |

| Top 5 Drug Type | Count |

|---|---|

| Monoclonal antibody | 9 |

| Biological products | 2 |

| Bispecific antibody | 2 |

| Antibody | 1 |

| Antibody drug conjugate (ADC) | 1 |

Related

16

Drugs associated with Twist Bioscience Corp.Target |

Mechanism SARS-CoV-2 S protein inhibitors |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhasePreclinical |

First Approval Ctry. / Loc.- |

First Approval Date- |

Target |

Mechanism GLP-1R agonists |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhasePreclinical |

First Approval Ctry. / Loc.- |

First Approval Date- |

Target |

Mechanism SARS-CoV-2 S protein modulators |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhasePreclinical |

First Approval Ctry. / Loc.- |

First Approval Date- |

100 Clinical Results associated with Twist Bioscience Corp.

Login to view more data

0 Patents (Medical) associated with Twist Bioscience Corp.

Login to view more data

5

Literatures (Medical) associated with Twist Bioscience Corp.01 Sep 2024·Applied Biosafety

Progress and Prospects for a Nucleic Acid Screening Test Set

Article

Author: Carter, Sarah R. ; Gemler, Bryan T. ; Bartling, Craig ; Diggans, James ; Flyangolts, Kevin ; Rife Magalis, Brittany ; Clore, Adam ; Beal, Jacob ; Wheeler, Nicole E.

Objective:

DNA synthesis companies screen orders to detect controlled sequences with misuse risks. Assessing screening accuracy is challenging owing to the breadth of biological risks and ambiguities in risk definitions. Here, we detail an International Gene Synthesis Consortium working group's rationale and process to develop a prototype DNA synthesis screening test dataset, aiming to establish a baseline of screening system accuracy to compare with various screening approaches.

Methodology:

Construction of the prototype test dataset involved four tool developers screening nucleic acid sequences from three taxonomic clusters of controlled organisms (Orbivirus, Francisella tularensis, and Coccidioides). Results were mapped onto predefined, comparable categories, checking for consensus or conflicts. Conflicts were grouped based on gene annotation and resolved through discussion.

Results:

The process highlighted several long-standing challenges in DNA synthesis screening, including the qualitative differences in approaches taken by screening tools. Our findings highlight the lack of clarity in assessing pathogen sequences with respect to regulatory control language, compounded by scientific uncertainty. We illustrate the current degree of consensus and existing challenges using classification statistics and specific examples.

Conclusions and Next Steps:

This prototype underscores the necessity of expert-regulator coordination in assessing gene-associated risks, offering a template for creating test sets across all taxonomic groups on international control lists. Expanding the working group would enrich dataset comprehensiveness, enabling a transition from species-focused to function-focused regulatory controls. This sets the foundation for quality control, certification, and improved risk assessment in DNA synthesis screening.

22 Jul 2023·Antibody therapeutics

Alpaca single B cell interrogation and heavy-chain-only antibody discovery on an optofluidic platform

Article

Author: Shapiro, Mariya B ; Brousseau, Anna ; Gao, Feng ; Kamat, Vishal ; Boucher, Jacqueline ; Dehkharghani, Amin ; Patil, Ketan ; Gabriel, Justin ; Walker, Jennifer ; Kelly, Ryan ; Souders, Colby A

Abstract:

In vivo VHH discovery approaches have been limited by the lack of methodologies for camelid B cell interrogation. Here, we report a novel application of the Beacon® optofluidic platform to the discovery of heavy-chain-only antibodies by screening alpaca B cells. Methods for alpaca B cell enrichment, culture, IgG2/3 detection, and sequencing were developed and used to discover target-specific VHH from an alpaca immunized with prostate-specific membrane antigen (PSMA) or a second target. PSMA-specific hits were expressed as VHH-Fc and characterized using label-free techniques. Anti-PSMA IgG2/3 titer plateaued on day 153, when on-Beacon IgG2/3 secretion and target binding rates peaked. Of 13 recombinantly expressed VHH-Fc, all but one bound with nanomolar affinity, and five were successfully humanized. Repertoire sequencing uncovered additional variants within the clonal lineages of the validated hits. The establishment of this workflow extends the powerful Beacon technology to enable rapid VHH discovery directly from natural camelid immune repertoires.

Frontiers in bioengineering and biotechnologyQ3 · ENGINEERING & TECHNOLOGY

Next Steps for Access to Safe, Secure DNA Synthesis

Q3 · ENGINEERING & TECHNOLOGY

ArticleOA

Author: Diggans, James ; Leproust, Emily

The DNA synthesis industry has, since the invention of gene-length synthesis, worked proactively to ensure synthesis is carried out securely and safely. Informed by guidance from the U.S. government, several of these companies have collaborated over the last decade to produce a set of best practices for customer and sequence screening prior to manufacture. Taken together, these practices ensure that synthetic DNA is used to advance research that is designed and intended for public benefit. With increasing scale in the industry and expanding capability in the synthetic biology toolset, it is worth revisiting current practices to evaluate additional measures to ensure the continued safety and wide availability of DNA synthesis. Here we encourage specific steps, in part derived from successes in the cybersecurity community, that can ensure synthesis screening systems stay well ahead of emerging challenges, to continue to enable responsible research advances. Gene synthesis companies, science and technology funders, policymakers, and the scientific community as a whole have a shared duty to continue to minimize risk and maximize the safety and security of DNA synthesis to further power world-changing developments in advanced biological manufacturing, agriculture, drug development, healthcare, and energy.

193

News (Medical) associated with Twist Bioscience Corp.22 Jan 2026

DELRAY BEACH, Fla., Jan. 22, 2026 /PRNewswire/ -- According to MarketsandMarkets™, the

Next-Generation Sequencing Market is projected to grow from about USD 14.94 billion in 2025 to USD 29.53 billion by 2030, at a CAGR of 14.6%.

Browse 1,100 market data tables and 65 figures spread through 720 pages and in-depth TOC on "NGS market- Global Forecast to 2030"

Next-Generation Sequencing Market Size & Forecast:

Market Size Available for Years: 2024–2030

2025 Market Size: USD 14.94 billion

2030 Projected Market Size: USD 29.53 billion

CAGR (2025–2030): 14.6%

Next-generation Sequencing Market Trends & Insights:

The next-generation sequencing market services segment is expected to register the highest CAGR of 18.2%.

In the next-generation sequencing market, by technology, the sequencing by synthesis segment will grow at a CAGR of 9.2%.

In the next-generation sequencing market, by application, the diagnostics segment is projected to grow at the fastest rate (13.9%) from 2025 to 2030.

The North American next-generation sequencing market accounted for a 41.8% revenue share in 2024.

Download PDF Brochure @

The main factors behind the expansion of this market are increased government funding for sequencing projects, rising applications of NGS in chronic disorders, and growing applications of NGS in clinical diagnostics.

Steady advances in bioinformatics and data analytics are key drivers of the NGS market's growth. These tools facilitate the processing of sequencing data and the extraction of valuable insights. Concurrently, a broader range of applications is becoming accessible as sequencing costs decline. Personalized medicine and genome research are also gaining momentum, driven by growing government funding and initiatives. Demand for sequencing solutions is rising as population genomics and large-scale sequencing initiatives provide deeper insights into genetic diversity and disease risk. Additionally, AI- and ML-enabled workflows are increasing efficiency and accuracy, accelerating innovation.

By

offering, the products segment accounted for the largest share in the next-generation sequencing market in 2024

The NGS market is segmented into products and services. The products segment accounted for the largest share of the NGS market in 2024. The products segment leads largely due to steady, recurring revenue from consumables, while the high price of NGS instruments also adds meaningful value to product sales. Services remain the second-largest segment in the market.

Request Sample Pages@

By platform technology, the sequencing by synthesis technology segment, accounted for the largest share in terms in 2024

The next-generation sequencing market is segmented into sequencing by synthesis, ion semiconductor sequencing, single-molecule real-time sequencing, nanopore sequencing, and other sequencing technologies. The segment comprising sequencing by synthesis constituted the largest share in 2024. This dominant share is attributed to the extensive use of the technique in genomics, transcriptomics, epigenomics, and metagenomics, thereby increasing its market penetration. The segment comprising ion semiconductor sequencing technologies held the second-largest share.

By service type, the products segment accounted for the largest share in the next-generation sequencing market in 2024

The next-generation sequencing market is segmented into sequencing services, presequencing services, bioinformatics and data analysis services, and NGS platform services. Sequencing services held the largest share in 2024, driven by large-scale genomics studies and programs run by governments and private organizations that often rely on established providers for high-throughput needs. Bioinformatics and data analysis services ranked second, supported by the growing volume and complexity of sequencing data.

By application, the diagnostics segment accounted for the largest share of the application segment in 2024.

The next-generation sequencing market is segmented into drug discovery & development, diagnostics, agriculture and animal research, and other applications. In 2023, the diagnostics segment accounted for the largest share of the NGS market. This can be attributed to declining sequencing costs, which have made NGS more accessible for routine diagnostic use in clinical labs and hospitals. Support for large-scale screening programs, such as newborn screening and population genomics projects, has also driven demand for NGS diagnostics.

By end user, the academic & research institutes segment accounted for the largest share of the product in the next-generation sequencing market in 2024.

The next-generation sequencing market is segmented into academic and research institutes, pharmaceutical and biotechnology companies, clinical and diagnostic laboratories, and other end users. Academic and research institutes held the largest share of the next-generation sequencing market in 2024. This is largely because NGS workflows are flexible and fit a wide range of custom study designs, aligning well with academic research needs. These institutes also lead early adoption of emerging areas such as single-cell sequencing and spatial transcriptomics, which depend on advanced NGS platforms and high consumable usage.

The North American region accounted for the largest share of the NGS market in 2024.

The NGS market is segmented into six major regions, namely North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. North America is the largest regional market for NGS in 2024, while Europe is the second largest.

The large share of North America can be attributed to the region's well-developed healthcare and research infrastructure, which supports the adoption of advanced NGS technologies in clinical and research settings. However, the Asia-Pacific region is estimated to be the fastest-growing segment of the market, owing to infrastructure development in developing countries, large-scale population genomics projects, and expanding collaborations among pharma and biotech companies for NGS testing and analysis.

Inquire Before Buying@

Top Companies in Next Generation Sequencing Market

:

The Top Companies in Next Generation Sequencing Market include Illumina, Inc. (US), Thermo Fisher Scientific Inc. (US), F. Hoffmann-La Roche Ltd. (Switzerland), Danaher Corporation (US), QIAGEN (Netherlands), Agilent Technologies, Inc. (US), Revvity (US), Eurofins Scientific (Luxembourg), PacBio (US), Oxford Nanopore Technologies plc. (UK), Takara Bio Inc. (Japan), BGI Group (China), Merck KGaA (Germany), BD (US), 10X Genomics (US), New England Biolabs (US), Promega Corporation (US), Novogene Co., Ltd. (China), LGC Limited (UK), WuXi Biologics (China), MGI Tech Co. Ltd. (China), Tecan Trading AG (Switzerland), Twist Biosciences (US), Azenta US, Inc. (US), GenScript (US), SD Biosensor, Inc. (South Korea), Fulgent Genetics (US), Hamilton Company (US), Zymo Research Corporation (US), NeoGenomics Laboratories (US), and Psomagen (US).

Browse Adjacent Markets:

Biotechnology Market Research

Reports & Consulting

Related Reports:

Single Cell Analysis Market

- Global Forecast to 2030

Life Science Instrumentation Market

- Global Forecast to 2031

Genomics Market

- Global Forecast to 2030

Drug Discovery Services Market

- Global Forecast to 2030

Molecular Diagnostics Market

- Global Forecast to 2030

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

To find out more, visit ™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441

Email: [email protected]

Visit Our Website:

Logo:

SOURCE MarketsandMarkets

21%

more press release views with

Request a Demo

02 Oct 2025

SOUTH SAN FRANCISCO, Calif.--(BUSINESS WIRE)--Twist Bioscience Corporation (NASDAQ: TWST), a mid-cap growth and value biotech company, today announced the publication in Science of the peer-reviewed paper, “Strengthening nucleic acid biosecurity screening against generative protein design tools,” led by Microsoft and co-authored with a consortium of scientific and industry experts including the International Gene Synthesis Consortium.

In a first-of-its-kind study to highlight the impact of AI on a particular industry, the publication highlights the importance of iterative improvement, cross industry collaboration and foresight in biosecurity screening. For known proteins and sequences, current biosecurity and screening practices work well today to detect and prevent misuse. As AI continues to unlock new possibilities in sequence and protein design, it is important to anticipate and mitigate potential misuse. Twist’s participation in this initiative, alongside key players in technology and life sciences research, exemplifies a proactive approach to safeguard public health, providing an example for other industries to follow.

“Since the inception of Twist, we have developed and advanced stringent biosecurity screening methods and standards in parallel with our commercial offerings. For known proteins and sequences, industry best practices for biosecurity screening are robust and highly effective. However, as AI capabilities evolve, screening practices must evolve just as quickly,” said Emily M. Leproust, CEO and co-founder of Twist Bioscience. “Recognizing the critical role that we play in the advancement of our customer’s research, together with Microsoft, we are looking around the corner to identify and guide industry next steps for impactful drug discovery while advancing science responsibly.”

“As AI opens new frontiers in the life sciences, we have a shared responsibility to continually improve and evolve safety measures,” said Dr. Eric Horvitz, Chief Scientific Officer of Microsoft and co-lead author of the study. “This research highlights the importance of foresight, collaboration, and responsible innovation. By partnering with Twist and other organizations in the synthetic DNA space to proactively identify and mitigate biosecurity risks, we help ensure that the benefits of AI in biology and medicine are realized with safety and care.”

The study revealed that AI-designed sequences of protein variants of toxins and viral proteins could escape detection by standard biosecurity screening software. While these were digital sequences only and it is unknown whether these engineered sequences would remain pathogenic once manufactured, this coordinated red-teaming effort resulted in improved detection protocols. Twist and its partners used these findings to develop patches and novel strategies that enhance screening accuracy of engineered protein sequences. Iterative and intentional development of protocols in dialogue with industry advocates, government entities, large technology companies and more, together with the use of multiple tools including AI to detect variants and new sequences that have the potential to be pathogenic, will ensure a focus on continuing safe and responsible research across industries.

About Twist Bioscience Corporation

At Twist Bioscience, we work in service of customers who are changing the world for the better. In fields such as medicine, agriculture, industrial chemicals and defense, by using our synthetic DNA tools, our customers are developing ways to better lives and improve the sustainability of the planet. The faster our customers succeed, the better for all of us, and Twist Bioscience is uniquely positioned to help accelerate their efforts.

Our innovative silicon-based DNA Synthesis Platform provides precision at a scale that is otherwise unavailable to our customers. Our platform technologies overcome inefficiencies and enable cost-effective, rapid, precise, high-throughput synthesis, sequencing and therapeutics discovery, providing both the quality and quantity of the tools they need to most rapidly realize the opportunity ahead. For more information about our products and services, please visit www.twistbioscience.com.

Follow us on LinkedIn | X | YouTube | Instagram | Bluesky

Twist Bioscience Legal Notice Regarding Forward-Looking Statements

This press release contains forward-looking statements. All statements other than statements of historical facts contained herein are forward-looking statements reflecting the current beliefs and expectations of management made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995, including statements regarding the evolution of biosecurity screening with advancing AI and the development of new standards for safe and responsible research. Forward-looking statements involve known and unknown risks, uncertainties, and other important factors that may cause Twist’s actual results, performance, or achievements to be materially different from any future results, performance, or achievements expressed or implied by the forward-looking statements. Such risks and uncertainties include, among others, the ability to attract new customers and retain and grow sales from existing customers; the ability of Twist to achieve sufficient revenue to achieve or maintain positive cash flow from operations or profitability in any given period; ability to obtain financing when necessary; risks and uncertainties of rapidly changing technologies and extensive competition in synthetic biology that could make the products Twist is developing obsolete or non-competitive; ability to expand DNA synthesis manufacturing capacity; dependence on one supplier for a critical component; dependence on key personnel; additional regulations that could increase Twist’s costs and delay commercialization efforts; changes in U.S. trade policies and other trade actions that could result in increased costs and supply chain disruptions; and the ability to maintain and enforce intellectual property protection. For a description of the risks and uncertainties that could cause actual results to differ from those expressed in these forward-looking statements, as well as risks relating to Twist’s business in general, see Twist’s risk factors set forth in Twist’s Annual Report on Form 10-K for the year ended September 30, 2024 filed with the Securities and Exchange Commission (SEC) on November 18, 2024 and subsequent filings with the SEC. Any forward-looking statements contained in this press release speak only as of the date hereof, and Twist specifically disclaims any obligation to update any forward-looking statement, whether as a result of new information, future events or otherwise.

02 Oct 2025

Ansa Biotechnologies secured $54.4 million in an oversubscribed series B round that it will use to expand the company’s DNA synthesis production capacity in the U.S.

Ansa Biotechnologies hauled in a total of $54.4 million in an oversubscribed series B round of financing that will be used to expand the company’s DNA synthesis production capacity in the U.S.The San Francisco-based biotech, which debuted in 2018, touts its platform as able to deliver DNA synthesis used by biopharmaceutical researchers and developers to create new diagnostics, therapeutics and other biomanufactured materials much faster and accurately than currently existing methods.The latest financing round closed with $45.2 million and commitments for an additional $9.2 million, the company said in an Oct. 1 press release. It was led by Cerberus Ventures with participation from Blue Water Life Science Advisors, Altitude Life Science Ventures and other existing investors. New investors include Fall Line Capital, AIM13 and Black Opal Ventures.To date, Ansa has raised more than $134 million in total fundraising.Additionally, Chenny Zhang, director at Cerberus Ventures, and Yanniv Dorone, senior vice president at Fall Line Capital, have been added to Ansa’s board of directors. “When you can deliver 50 kb of clonal DNA in 24 days or less, when you’re the only company bold enough to guarantee entire orders, and when you keep innovating on behalf of customers instead of protecting the status quo, you don’t just compete, you reset the rules,” Jason Gammack, Ansa’s chief executive, said in the release. “This financing is fuel for the next phase of our mission: to make DNA something scientists can count on, every single time.”The company’s DNA synthesis was developed by co-founders Daniel Lin-Arlow, Ph.D., and Sebastian Palluk, Ph.D., and uses enzymes for a more natural process of building DNA sequences versus other methods, which may use harsh chemicals that can weaken the newly created molecules.Ansa’s approach is different from others that typically build sequences by adding modified nucleotides one at a time. Ansa’s approach binds nucleotides to a DNA polymerase before adding them to the sequence, which the company has said provides a faster, more cost-effective synthesis.Other companies that have followed the enzymatic path to DNA synthesis include Twist Bioscience and DNA Script.

Oligonucleotide

100 Deals associated with Twist Bioscience Corp.

Login to view more data

100 Translational Medicine associated with Twist Bioscience Corp.

Login to view more data

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 07 Feb 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Discovery

4

12

Preclinical

Other

2

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

RBT-0813 ( SARS-CoV-2 S protein ) | COVID-19 More | Preclinical |

TB-222-023 ( GLP-1R ) | Hyperinsulinism More | Preclinical |

anti-CD40 agonistic antibodies(Twist Bioscience) ( CD40 ) | Neoplasms More | Preclinical |

4-1BB/Nectin-4 bispecific antibody (Twist Bioscience) ( 4-1BB x nectin-4 ) | Neoplasms More | Preclinical |

TB202-63 | COVID-19 More | Preclinical |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

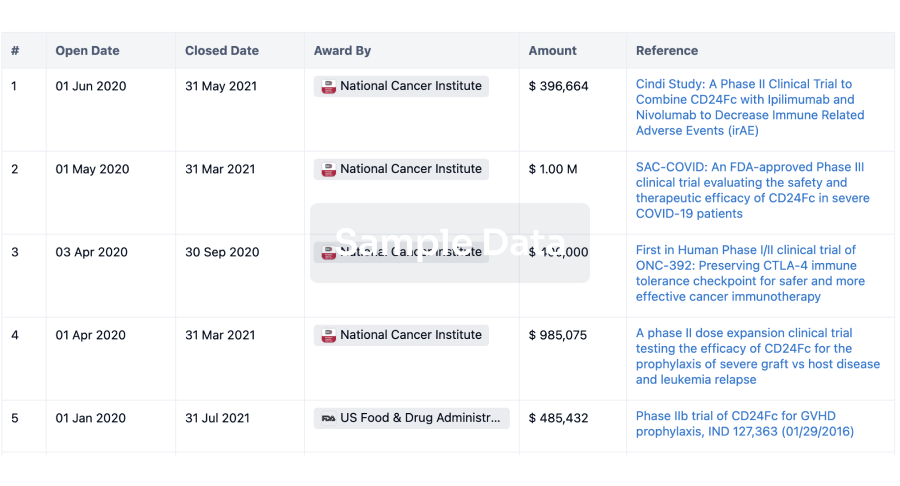

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free