Request Demo

Last update 08 May 2025

Beijing Anzhen Hospital

Last update 08 May 2025

Overview

Related

5

Drugs associated with Beijing Anzhen HospitalTarget- |

Mechanism Immunologic cytotoxicity |

Active Org.- |

Originator Org. |

Active Indication- |

Inactive Indication |

Drug Highest PhaseSuspended |

First Approval Ctry. / Loc.- |

First Approval Date- |

Target- |

Mechanism- |

Active Org.- |

Originator Org.- |

Active Indication- |

Inactive Indication |

Drug Highest PhaseSuspended |

First Approval Ctry. / Loc.- |

First Approval Date- |

Target- |

Mechanism- |

Active Org.- |

Originator Org. |

Active Indication- |

Inactive Indication |

Drug Highest PhasePending |

First Approval Ctry. / Loc.- |

First Approval Date- |

263

Clinical Trials associated with Beijing Anzhen HospitalNCT06872021

Early Intra-aortic Balloon Pump Use After Venoarterial Extracorporeal Membrane Oxygenation: the EASE-ECMO Randomized Clinical Trial

The goal of this multicenter, randomized trial is to compare early early left ventricular unloading by Intra-aortic Balloon Pump (IABP) versus conventional approach in patients with cardiogenic shock (CS) undergoing venoarterial extracorporeal membrane oxygenation (VA-ECMO). The main question it aims to answer is :

• If left ventricular unloading by IABP as compared with the conventional approach will improve the outcomes in patients undergoing VA-ECMO.

• If left ventricular unloading by IABP as compared with the conventional approach will improve the outcomes in patients undergoing VA-ECMO.

Start Date01 Sep 2025 |

Sponsor / Collaborator |

NCT06871228

DIscontinuation of Anticoagulation MONitoreD by Smartwatch Versus Continuous Anticoagulation in Post-ablation Patients with Atrial Fibrillation: a Randomized Controlled Trial

The DIAMOND-AF trial, an investigator-initiated multicenter study, randomizes 5,694 stroke-free AF patients with a CHA₂DS₂-VA score of 2-6 post-successful ablation to either smartwatch-guided intermittent direct oral anticoagulant (DOAC) therapy (30-day treatment triggered by AF episodes ≥1 hour single or ≥2 hours/24h) or continuous DOAC therapy. The trial assesses the superiority of intermittent DOAC therapy in reducing major bleeding (ISTH) compared to continuous DOAC therapy, and the non-inferiority of intermittent DOAC in preventing thromboembolism (stroke, embolism, and cardiovascular death) over a 48-month follow-up, aiming to tailor anticoagulation strategies in patients with rhythm control achieved through ablation.

Start Date01 Jul 2025 |

Sponsor / Collaborator |

NCT06946095

Efficacy and Safety of Xinyue Capsule in the Treatment of Heart Failure With Preserved Ejection Fraction: A Clinical Study

The purpose of this study is to evaluate the effect of Xinyue Capsule in the improvement cardiac function and reduction the level of heart failure biomarker NT-proBNP in patients suffering from HF with an ejection fraction greater than or equal to 50%. Researchers will also collect information on how much the heart disease has impact on patient's lives, and how well Xinyue Capsule treatment is tolerated. The study plans to enroll 246 male and female patients of the age of 18 years and above suffering from heart failure with ejection fraction greater than or equal to 50%. Participants will take the study product as oral tablet with a dose 0.6 g Tid daily. Study duration will be up to 12 weeks.

Start Date20 May 2025 |

Sponsor / Collaborator |

100 Clinical Results associated with Beijing Anzhen Hospital

Login to view more data

0 Patents (Medical) associated with Beijing Anzhen Hospital

Login to view more data

847

Literatures (Medical) associated with Beijing Anzhen Hospital31 Dec 2025·Renal Failure

Assessment of renal insufficiency in patients with renal artery stenosis by multiparametric magnetic resonance imaging

Article

Author: Wang, Guo-Qin ; Sun, Zhong-Hua ; Zhao, Long ; Xu, Lei ; Li, Shuang ; Zhang, Nan ; Liu, Jia-Yi ; Xu, Feng-Bo

15 May 2025·Rapid Communications in Mass Spectrometry

Systematic Profile of Oxylipins in Myocardial Infarction by Liquid Chromatography–Tandem Mass Spectrometry

Article

Author: Li, Qin ; Ni, Hui ; Tan, Xin ; Ma, Zhanglin

11 Apr 2025·Circulation Research

GOLM1 Promotes Atherogenesis by Activating Macrophage EGFR-ERK Signaling Cascade

Article

Author: Wu, Yuting ; Liu, Fangming ; Deng, Weiwei ; Zhang, Yinliang ; Chen, Linlin ; Gai, Xiaochen ; Du, Jie ; Yu, Cuntao ; Zhang, Hongbing ; Wang, Shuiyun ; Zhang, Baohui ; Yang, Shuhui ; Zhang, Zhengyi ; Wang, Jing ; Wang, Yuan ; Chen, Yixin

8

News (Medical) associated with Beijing Anzhen Hospital18 Feb 2025

TUESDAY, Feb. 18, 2025 -- For patients with large vessel occlusion presenting between 4.5 and 24 hours, intra-arterial

tenecteplase

after successful thrombectomy results in improved likelihood of excellent outcome (modified Rankin scale score 0 to 1), according to a study presented at the annual American

Stroke

Association International Stroke Conference, held from Feb. 5 to 7 in Los Angeles.

Xiaochuan Huo, M.D., Ph.D., from Beijing Anzhen Hospital, and colleagues conducted a multicenter, prospective, randomized trial involving patients with acute anterior circulation large vessel occlusion treated between 4.5 and 24 hours from the time last known to be well. After successful endovascular recanalization, patients were randomly assigned to receive intra-arterial tenecteplase or standard medical management (127 and 129 participants, respectively).

The researchers found that the percentage of patients with a modified Rankin scale score of 0 or 1 at 90 days was higher with intra-arterial tenecteplase versus standard medical treatment after endovascular therapy (40.5 versus 26.4 percent; relative rate, 1.44; 95 percent confidence interval, 1.06 to 1.95). Mortality at 90 days did not differ significantly between the groups and was 21.4 and 21.7 percent with intra-arterial tenecteplase and standard medical treatment, respectively. There was no significant difference seen in the incidence of symptomatic intracranial hemorrhage within 48 hours after treatment (5.6 and 6.2 percent with intra-arterial tenecteplase and standard medical treatment, respectively).

"Intra-arterial tenecteplase after successful thrombectomy could improve the percentage of people with an excellent outcome," Huo said in a statement. "It could also improve the rate of large vessel occlusion stroke survivors who can return to society and live independently."

Press Release

More Information

Whatever your topic of interest,

subscribe to our newsletters

to get the best of Drugs.com in your inbox.

Clinical ResultClinical Study

08 Mar 2024

WUXI, China, March 7, 2024 /PRNewswire/ -- Silk Road Medical (NASDAQ: SILK), a medical device company based in California USA and Genesis MedTech Group have signed an exclusive distribution agreement to introduce the TCAR® core products, ENROUTE® Transcarotid Neuroprotection System and ENROUTE® Transcarotid Stent System, in China. TCAR (Transcarotid Artery Revascularization) is an innovative minimally invasive surgical procedure used to treat carotid artery disease, a condition characterized by the narrowing or blockage of the carotid arteries in the neck. This narrowing or blockage can restrict blood flow to the brain and increase the risk of stroke.

Since its establishment in 2019, Genesis MedTech Group has continuously strived to enhance its peripheral interventional portfolio, offering comprehensive solutions to both physicians and patients. Through its commercial team and distribution network, patients in China will now have access to the core TCAR products, the ENROUTE® Neuroprotection System and Stent Delivery System. TCAR has shown to reduce the risk of stroke, death, myocardial infraction (MI), and Cranial Nerve Injury (CNI). It is a less invasive procedure with lower rates of procedural complications and an overall improvement in outcomes, contributing to a positive impact on healthcare.

Carotid artery disease often occurs in the middle-aged and elderly population, especially among those with atherosclerosis. The condition is characterized by the buildup of plaque, and over time can cause narrowing or blockage of the carotid arteries, affecting blood supply to the brain and leading to diseases such as ischemic stroke. In recent years, stroke has become the second leading cause of mortality worldwide. In China, it now ranks as the primary cause of death and disability. Each year, over 17 million strokes affect individuals over 40 years old. Notably, around one third of ischemic strokes are caused by carotid artery disease.

In the United States, TCAR is rapidly replacing traditional procedures. As of the end of 2023, over 85,000 TCAR procedures have been performed. Before the introduction of TCAR, moderate to severe carotid artery disease was generally treated clinically with two surgical methods: Carotid Endarterectomy (CEA) and Transfemoral Carotid Artery Stenting (TFCAS). However, CEA involves a large incision and carries a higher risk of complications, posing a risk of damage to the cranial nerves of patients. Studies have also shown a higher risk of stroke during TFCAS as compared to TCAR and CEA. Based on clinical studies, TCAR is an advancement in the management of carotid artery disease.

Professor Chen Zhong, Chairman, Vascular Surgery Group of Chinese Medical Association, President, Vascular Surgery Physicians Branch of Chinese Medical Doctor Association and Chief Physician, Vascular Surgery at Beijing Anzhen Hospital, commented, "There is considerable evidence showing that TCAR offers advantages for patients with symptomatic carotid artery stenosis or those at anatomical or surgical risk."

Silk Road Medical's CEO, Chas McKhann stated, "This agreement represents a promising initial step towards expanding the reach of the TCAR therapy with the offering of our ENROUTE Neuroprotection System and Stent Delivery System to more patients worldwide, including those in China. We are very pleased to have partnered with Genesis MedTech, a respected leader in medtech, who shares our vision for the potential impact of TCAR in preventing strokes."

"Enabling TCAR to be made accessible to the patients in China certainly marks another milestone in our efforts to bring innovative treatments to our patients. Together with Silk Road Medical, we remain dedicated to make better healthcare more accessible, improving patient care and outcomes." shared Warren Wang, Genesis MedTech Group's Chairman and CEO.

ABOUT GENESIS MEDTECH

Genesis MedTech Group is a medical device company headquartered in Singapore. Founded by a group of professionals and entrepreneurs with MedTech experience globally, the company's product portfolio focuses on multi-therapy medical device products for emerging markets with sales and distribution through its established commercial network. Genesis MedTech Group covers the entire industry value chain of research and development, production, quality management, supply chain, marketing, and sales.

For more information, visit

ABOUT SILK ROAD MEDICAL and TCAR

Silk Road Medical, Inc. (NASDAQ: SILK), is a medical device company located in Sunnyvale, California, and Plymouth, Minnesota, that is focused on reducing the risk of stroke and its devastating impact. The company has pioneered a new approach for the treatment of carotid artery disease called TransCarotid Artery Revascularization (TCAR). TCAR is a clinically proven procedure combining surgical principles of neuroprotection with minimally invasive endovascular techniques to treat blockages in the carotid artery at risk of causing a stroke. For more information on how Silk Road Medical is delivering brighter patient outcomes through brighter clinical thinking, visit and connect on Twitter, LinkedIn and Facebook.

References

SOURCE Genesis MedTech

License out/in

26 Feb 2024

With the accelerated ageing of the global population and the trend towards paying attention to healthcare, people concern more about health checkup, disease prevention and regular screening. This leads to an increase in market demand for medical devices and consumables.

According to a market analysis report published by Fortune Business Insights, the global market volume of medical devices and consumables is expected to grow at a CAGR of 5.9% from $536.12 billion in 2023 to $799.67 billion by 2030.

The US is the world's leading manufacturing country of medical devices and the world's largest market of medical devices and consumables. In the rankings of the “World's top 10 pharmaceutical companies” and “World's top 10 medical device companies”, the US accounts for the largest share with four and seven companies respectively.

China follows in the second place. China's market of medical devices and consumables is facing both challenges and opportunities with the continuous promotion of centralised VBP (volume-based procurement) and DRG (diagnosis related groups) medical insurance reform. As a result, there is high potential to grow in innovative medical devices and high-value consumables.

Continuous breakthrough in material science and processing technology is crucial to the development of medical device, equipment, consumables and pharmaceutical packaging. Polymers are biocompatible, durable, easy to process and stable in quality, contributing to the user-friendly design and safety of medical products.

Interventional cardiology: PLCL and UHMWPE materials shine

Interventional cardiology device is the largest sector of high-value medical consumable, accounting for more than 30% of the market. Mid- to high-end products are mainly manufactured by foreign manufacturers, such as Medtronic, Johnson & Johnson, and Boston Scientific.

The sector mainly includes stents, pacemakers and valves. The main materials of these consumables are nickel-titanium alloy, cobalt-chromium alloy, medical-grade high molecular weight poly(L-lactide-co-caprolactone) (PLCL), and ultra-high molecular weight polyethylene (UHMWPE).

Beijing Advanced Medical Technologies cooperates with Department of Material Science of Fudan University to develop PLCL 95/5 polymer. The Chinese company also teams up with Beijing Anzhen Hospital and Beijing Jishuitan Hospital to conduct research on the new generation of absorbable PLCL coronary stents.

The high-end UHMWPE fibre product market is dominated by companies including DSM, Honeywell, and Toyobo. For example, Honeywell's Spectra MG medical grade fibres are made of UHMWPE fibre with a patented gel spinning production process.

UHMWPE manufactured by Chinese companies are mainly mid- to low-end products.

Orthopaedics: PEEK, PU, and PMMA are the material of choice

In addition to interventional cardiology device, orthopaedic device has also become a fast-growing segment of medical device applications in recent years. The high age-related incidence of orthopaedic diseases is the major contributor, resulting in the increased demand for orthopaedic device in elderly population.

As one of the largest segments in the medical device industry, the orthopaedic device segment consists of two parts: orthopaedic implantable devices and specialised surgical instruments, with the former account for 90%. Orthopaedic implantable devices mainly include craniofacial and maxillofacial implants, spinal fusion interbody cages, joint implants, fixation plates, and screws. Apart from titanium alloy and stainless steel, commonly used materials are Polyether ether ketone (PEEK), polyurethane (PU) and polymethyl methacrylate (PMMA), etc.

Complying with the clinical standards, these implantable materials cannot be rejected by the human body and do not produce harmful matters. Meanwhile, these materials must be able to produce optimal structures at an affordable price.

The stiffness of PEEK closely matches with human bone and the polymer has the properties of radiolucency and reduced stress shielding. As such, PEEK has high market potential in medical applications and is mainly used in the manufacture of spinal and joint implants.

Curiteva, US-based technology and manufacturing company has developed a spinal implant made of Evonik VESTAKEEP i4 3DF PEEK filament biomaterial. The 3D-printed implant received clearance from the FDA and it is the first such device for commercial use.

The PEEK spinal cage implant developed by Bond3D in the Netherlands is translucent under X-ray or CT scans. It allows bone ingrowth, provides a secure fit and can reduce production cycle.

Tangdu Hospital of Air Force Medical University in China created skull, sternal and rib implants with PEEK, using INTAMSYS’ 3D printing equipment.

Drug delivery: COC and PC+ABS optimise user-friendliness

Like orthopaedic devices, drug delivery devices are growing rapidly. Allied Market Research forecasts the market of global drug delivery systems to grow at a CAGR of 16%, achieving a market volume of approximately $195.1 billion by 2030.

Drug delivery devices are mainly used to protect drugs from environmental contamination to ensure safe implementation of drugs. The main product types include implantable, mucosal, injecting devices, etc.

Medtronic has introduced an infusion set for insulin infusion that can be worn for up to seven days for patients with diabetes, while infusion sets on the market typically need to be replaced every two to three days. Medtronic says that the infusion set can save up to 25% of insulin costs and reduce plastic waste by up to 50% on a yearly basis.

SCHOTT Pharma uses advanced cyclic olefin copolymer (COC) to make prefilled syringes (PFS) that can be stored at ultra-low temperature of -100°C. The syringes are fracture-resistant, biologically inert and of superior barrier property to ensure drug stability.

Beijing QS Medical Technology has optimised the design of its insulin needle-free syringes with Covestro's environmental friendly, flame-retardant polycarbonate and acrylonitrile-butadiene-styrene copolymer blend (PC+ABS), which is designed to make the product structure more robust and reliable.

Medical packaging: Plastic bottle and blister packaging grow

The boom in medical devices and consumables has led to the growth of the medical packaging market. According to Future Marketing Insights, the global medical packaging market is expected to reach $12.4 billion in revenues in 2023, and it will grow at a CAGR of 6.1% to reach $20.9 billion by 2033. The medical packaging market in China is expected to reach $12.7 billion in 2033.

At present, pharmaceutical packaging is developing in four major directions: patient-led demand packaging design, rising demand for plastic bottles and blister packaging, attention to child safety and sustainability.

The plasticisation of oral solution bottle packaging is one of the emerging trends in the transformation of pharmaceutical packaging. For example, Berry Global launched a plastic alternative for oral solution bottle packaging. Compared with glass bottles, the plastic bottle not only saves the material costs, but also reduces production costs by eliminating the complex processes required for manufacturing traditional glass bottles, such as bottle blowing, bottle washing and light inspection. Such bottles are easy to transport as well.

Elkem's Silbione series of medical silicone rubber materials and Polyplastics' medical-grade polyoxymethylene (POM) can be used to make drug delivery systems.

Medical equipment: Demand for functional plastics on the rise

In addition to the above-mentioned medical devices and consumables, soft and rigid endoscopes, CT, MRI, ultrasound, ventilators, anaesthesia machines, hemodialysis machines, and other medical equipment have become development focus for the medical plastics industry in recent years.

Röchling has developed POM, PEEK, Polyethylenimine (PEI) and glass-filled nylon (PA+GF) materials that can be used to manufacture ventilator shells, valves, switches, guide rails, sockets, adapters, cylinders, clamps and other components.

Besides, Röhm’s high-performance Cyrolite acrylics, which are ultra-high transparency and excellent sterilisation resistance, are easy to be processed into precision parts. They can be used for dialysis equipment and other medical devices and consumables in contact with blood, vitro diagnostics, surgical lighting, as well as a wide range of applications from the intensive care unit to the general operating room and laboratories.

INEOS Styrolution's acrylonitrile-styrene-acrylate (ASA) polymer "MED" is designed for small medical devices in homes and hospitals. It has excellent chemical resistance, UV resistance and impact strength.

Amcor China has launched mono-material recyclable packaging AmPrima and transparent sterilisation-resistant high-barrier recyclable packaging material AmLite, which were designed based on recyclability guidelines for flexible packaging.

Medical packaging manufacturer Nelipak uses Eastar Renew 6763, Eastman's recycled copolyester, to manufacture rigid thermoformed sterile barrier packaging.

Advanced processing and automation reduce cost and increase efficiency

High-quality manufacturing of medical devices and consumables cannot be achieved without precision processing and moulding.

The 32-cavity injection moulding machine of Fanuc for producing medical needle tubes has a screw diameter of 48mm, the cycle time is 11.75 seconds; LKIMM’s EL 130 injection moulding machine, which is suitable to produce pipette tips, uses non-contact tie bar and has a mould clamping position control accuracy of 0.01mm.

Jwell Machinery’s twin-screw drying-free PET medical packaging material production line can effectively reduce the viscosity of PET resin; Gowin Precision Machinery adopts the pre-filled series of multi-cavity precision moulds, which improve the yield of molecular diagnostic kit products.

In addition to moulding, the production of medical devices and consumables also includes inspection, testing, packaging, and storage. With the development of Industry 4.0, automation technology has gained wider application in production processes, helping manufacturers to reduce production costs and improve operating efficiency.

Shanghai Mitrassist Medical has realised fully automated industrial production of bioprosthetic valves, which originally required more than 2,000 stitches by hand, lowering the cost of the transcatheter aortic valve replacement (TAVR) system made of high molecular materials from RMB 40,000-50,000 to less than RMB 1,000.

Hunan Vathin Medical Instrument has designed an automated assembly line for endoscopes, enabling annual production capacity of up to 400,000 units while reducing costs by nearly 30%. APON Corporation, based in Jiangsu, has adopted an automated production line for its nasal hygiene products, enabling an annual production capacity of up to 10 million bottles.

Besides, the blood collection needle automated production line introduced by Maider, a specialist in automation equipment in consumables, effectively solves the bottlenecks of complicated components/processes, low efficiency of manual assembly, high risk of contamination, and unstable quality.

Positive response to health concerns

Innovation in medical devices, consumables, equipment and pharmaceutical packaging is not only technological progress, but also a positive response to global health concerns. Thanks to their material and processing advantages, polymer materials not only improve safety, but also enhance the patient experience and promote the sustainable development of the medical industry. With the continuous iteration in the industry, the future of medical polymer materials and related processing is promising.

100 Deals associated with Beijing Anzhen Hospital

Login to view more data

100 Translational Medicine associated with Beijing Anzhen Hospital

Login to view more data

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 23 Feb 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Other

5

Login to view more data

Current Projects

| Drug(Targets) | Indications | Global Highest Phase |

|---|---|---|

Autologous NK cells(Beijing Anzhen Hospital) | Metastatic castration-resistant prostate cancer More | Suspended |

Technetium Tc 99M Nitridocade | Contrast agents More | Pending |

Methyldithiocarbazate and stannous chloride | Contrast agents More | Pending |

N-NOET | Contrast agents More | Pending |

Pituitrin | Vasoplegia More | Pending |

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

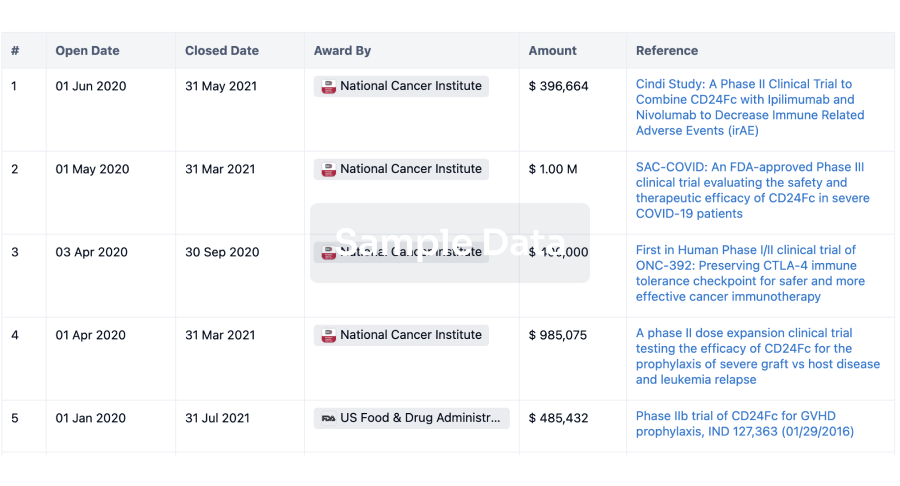

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free