Request Demo

Last update 19 Jan 2026

CanSino Biologics, Inc.

Last update 19 Jan 2026

Overview

Basic Info

Introduction CanSino Biologics is a company that specializes in the research, production, and marketing of vaccines. Their product line includes shingles, meningitis, polio, adenovirus, and tuberculosis vaccines. The company was established in 2009 by a group of individuals including Xuan Liu, Xue Feng Yu, Tao Zhu, Dong Xu Qiu, and Hui Hua Mao, and is based in Tianjin, China. |

Tags

Infectious Diseases

Respiratory Diseases

Other Diseases

Prophylactic vaccine

Recombinant vector vaccine

Conjugated vaccine

Disease domain score

A glimpse into the focused therapeutic areas

No Data

Technology Platform

Most used technologies in drug development

No Data

Targets

Most frequently developed targets

No Data

| Disease Domain | Count |

|---|---|

| Infectious Diseases | 26 |

| Nervous System Diseases | 9 |

| Neoplasms | 2 |

| Top 5 Drug Type | Count |

|---|---|

| Prophylactic vaccine | 26 |

| Conjugated vaccine | 6 |

| Recombinant vector vaccine | 5 |

| mRNA vaccine | 5 |

| Combination vaccine | 4 |

Related

29

Drugs associated with CanSino Biologics, Inc.Target- |

Mechanism Immunostimulants |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhaseApproved |

First Approval Ctry. / Loc. China |

First Approval Date17 Jun 2025 |

Target |

Mechanism SARS-CoV-2 antigen inhibitors [+1] |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhaseApproved |

First Approval Ctry. / Loc. China |

First Approval Date03 Dec 2023 |

Target |

Mechanism SARS-CoV-2 antigen inhibitors |

Active Org. |

Originator Org. |

Active Indication |

Inactive Indication- |

Drug Highest PhaseApproved |

First Approval Ctry. / Loc. China |

First Approval Date04 Sep 2022 |

64

Clinical Trials associated with CanSino Biologics, Inc.CTR20253929

评价吸附无细胞百(三组分)白破b型流感嗜血杆菌(结合)-ACYW135群脑膜炎球菌(结合)联合疫苗在2月龄~6岁人群中接种的安全性及免疫原性的随机、部分盲法、剂量探索、阳性/安慰剂对照Ⅰ期临床试验

[Translation] A randomized, partially blinded, dose-finding, active/placebo-controlled phase I clinical trial to evaluate the safety and immunogenicity of a three-component adsorbed acellular pertussis Haemophilus influenzae type b (conjugated)-ACYW135 group meningococcal (conjugated) vaccine in people aged 2 months to 6 years.

主要目的:

1.初步评价在2月龄~6岁人群中接种两种剂量DTcP-Hib-MCV4疫苗的安全性。

2.评价在2月龄婴儿中接种MCV4的安全性。

次要目的:

初步评价在2月龄婴儿中接种两种剂量DTcP-Hib-MCV4疫苗的免疫原性。

[Translation]

Primary Objectives:

1. To preliminarily evaluate the safety of two doses of DTcP-Hib-MCV4 vaccine in children aged 2 months to 6 years.

2. To evaluate the safety of MCV4 vaccination in 2-month-old infants.

Secondary Objectives:

To preliminarily evaluate the immunogenicity of two doses of DTcP-Hib-MCV4 vaccine in 2-month-old infants.

Start Date19 Dec 2025 |

Sponsor / Collaborator |

NCT07203755

A Randomized, Partially Blinded, Dose-Exploratory, Active/Placebo-Controlled Phase I Clinical Trial Evaluating the Safety and Immunogenicity of the Adsorbed Acellular Pertussis (Tricomponent) DPT-Hib (Conjugate)-ACYW135-Group B Meningococcal (Conjugate) Combined Vaccine in Individuals Aged 2 Months to 6 Years

This clinical trial is conducted in two parts. Part One employs a randomized, partially blinded, dose-escalation, partially active-controlled design. Part Two utilizes a randomized, blinded, placebo-controlled design. Part One is divided into four stages based on age and vaccine dose levels. Part Two consists of the 2-month-old vaccine/placebo groups.

Start Date19 Dec 2025 |

Sponsor / Collaborator |

NCT06732583

A Phase I Randomized, Double-blind, Placebo-controlled and Dose Escalation Study to Evaluate the Safety and Immunogenicity of a Viral Vector-based Tuberculosis (TB) Vaccine Ad5-105K Against TB Disease in Adults Aged 18 to 49 Years

This is a randomized, observer-blind, positive-controlled study. There will be 2 treatment groups (Group A and B). In each treatment group, 18 participants will be randomly assigned to receive either the investigational vaccine (Dose A or Dose B of Ad5-105K) or a placebo in a ratio of 2:1. The distribution of participant's gender and age should be balanced in each group.

Start Date13 Nov 2025 |

Sponsor / Collaborator |

100 Clinical Results associated with CanSino Biologics, Inc.

Login to view more data

0 Patents (Medical) associated with CanSino Biologics, Inc.

Login to view more data

41

Literatures (Medical) associated with CanSino Biologics, Inc.01 Dec 2025·BIOMATERIALS

Cost-effective yet high-performance ionizable lipids for mRNA-lipid nanoparticle vaccines

Article

Author: Liu, Lixin ; Qiao, Dongdong ; Yang, Haihong ; Chen, Yongming ; Ge, Xiaofei ; Liu, Zhijia ; Liu, Hong ; Zhu, Tao ; Gao, Zhan ; Yan, Zhihong ; He, Zepeng ; Wei, Lai ; Zhou, Yizi ; Wang, Haomeng

Ionizable lipids (ILs) are critical components in mRNA vaccines, which have been instrumental in the global response to SARS-CoV-2. However, current commercialized ILs in mRNA vaccines are typically synthesized through multiple-step organic reactions, complicating quality control and driving up production costs. To address this, we have developed novel ILs by a one-pot Ugi four-component reaction (Ugi-4CR), significantly simplifying synthesis while maintaining high yields and reducing costs. Here, from a library of 161 ILs, we chose six ILs with high expressing luciferase and investigated their performance in delivering the mRNA vaccine of SARS-CoV-2. These ILs feature distinct ionizable heads, N,N-dimethylethyl (R1), N,N-dimethylpropyl (R2), and N,N-diethylpropyl (R3), paired with hydrophobic tails of varying unsaturation, cis-9-octadecenoic (U1) and (9Z,12Z)-9,12-octadecadienoic (U2), respectively. In murine models, R2-and R3-based mSpike-LNPs induce higher antibody titers and stronger cellular immune responses compared to the R1-based counterparts, suggesting their superior mRNA delivery and expression efficiency. Notably, R2U2- and R3U2-based mSpike-LNPs further enhance IFN-γ+ splenocyte responses and activation of TNF-α+CD4+/CD8+ T cells, coupled with improved dendritic cell activation and retention in lymph nodes. We confirm that the R2U2-based LNPs on different mRNA antigens exhibit immune responses and safety profiles comparable to the commercial ALC-0315-based LNPs. Moreover, intranasal and intratracheal administration of R2U2-based mSpike-LNPs enhances mucosal immunity, as evidenced by elevated sIgA levels in mice. Further evaluation in cynomolgus macaques proves the efficacy of this LNP system, highlighting its potential for developing cost-effective mRNA vaccines.

13 Aug 2025·ACS Applied Materials & Interfaces

TUBB3/DTX LNPs Dry Powder Inhaler and an Efficient Delivery Device for Targeted Therapy of Lung Cancer

Article

Author: Sun, Hua ; Li, Mingyuan ; Ma, Wenlin ; Xu, Mengju ; Peng, Shaodan ; Zhao, Xiaolong ; Yin, Mengsi ; Zhang, Faxin ; Ma, Jingsi ; Zhou, Jiaping ; Wu, Ziqi ; Cheng, Yan ; Su, Wen ; Ren, Hongmeng ; Liang, Xiaofu ; Si, Weixue ; Yu, Jinhao ; Wang, Xianglong ; Deng, Jiang ; Che, Linze

Lung cancer is the most prevalent and deadly tumor globally, marked by drug resistance and a poor prognosis. Specialized formulations with strong lung targeting are currently lacking. Docetaxel (DTX) and TUBB3-siRNA represent chemotherapy and RNA interference (RNAi), two strategies for lung cancer treatment. Lipid nanoparticles (LNPs) are nanocarriers suitable for nucleic acid delivery. In this study, spray freeze-drying (SFD) converted LNP colloidal solutions into inhalable dry powders. Fresh and rehydrated LNP (SFD) showed sizes below 200 nm, ζ potentials near 0 mV, and uniform roundness by transmission electron microscopy. The geometric particle size distribution (D50) of TUBB3-LNPs, DTX-LNPs, and TUBB3/DTX-LNPs inhalable powders did not differ significantly (1.99-5.90 μm). The median mass aerodynamic diameter (MMAD) was 2.61 ± 0.32 μm, suitable for pulmonary deposition. Experiments with BEAS-2B and H460 cells showed that TUBB3/DTX-LNPs had low cytotoxicity and good biocompatibility with BEAS-2B but strongly inhibited H460 cells. Differences in apoptosis induced by fresh LNPs and rehydrated LNP (SFD) indicate that the SFD process preserves normal cell viability while maintaining tumor inhibition. Because dry powder inhalers combine the drug formulation with the delivery device, a specialized single-dose prefilled device was developed that featured four symmetrically configured orifices (vents) located in the middle of the tube body; it achieved a high dry powder emptying rate of 95-100%. Furthermore, this study demonstrated the lung-targeting efficacy and sustained-release properties of the formulation.

25 Jun 2025·ACS Applied Materials & Interfaces

Ionizable Sterol Lipid-Based Three-Component Lipid Nanoparticles for Localized Delivery of mRNA Vaccine with Stronger Cellular Immune Responses

Article

Author: Zhu, Tao ; Wang, Qingbin ; Wang, Haomeng ; Li, Jin ; Zhao, Xuan ; Yu, Xuefeng ; Yan, Zhihong ; Yan, Shengyong ; Wang, Zhenghua

Lipid nanoparticles (LNPs) have shown great promise for nucleic acid drug delivery. Canonical LNPs consist of four lipid components: ionizable lipid, cholesterol, Polyethylene glycol-yl-lipid (PEGyl-lipid), and phospholipid. However, these traditional LNPs face limitations in mRNA vaccine delivery, including liver-targeted transfection and the insufficient activation of cellular immune responses. A more efficacious and safer LNP system remains a great challenge. Herein, we report ionizable sterol lipid-based three-component LNPs (ISL-3C-LNPs), which exhibit high mRNA encapsulation and delivery efficiency. Among these, CS22021-based ISL-3C-LNP demonstrated localized mRNA delivery at the injection site following intramuscular administration, which potentially contributes to a good safety profile. Moreover, the CS22021-based ISL-3C-LNP enabled the efficient delivery of a varicella-zoster virus (VZV) mRNA vaccine by eliciting robust humoral and cellular immune responses. Notably, it elicited a significantly higher CD8+T cell response compared to a conventional LNP formulation, highlighting its potential in mRNA vaccine applications requiring enhanced CD8+T cell activation, such as mRNA cancer vaccines.

82

News (Medical) associated with CanSino Biologics, Inc.31 Dec 2025

SHANGHAI, Dec. 30, 2025 /PRNewswire/ -- Insilico Medicine (03696.HK), a global leader in AI-driven drug discovery and a portfolio company of Qiming Venture Partners, today successfully listed on the Hong Kong Stock Exchange (HKEX). The listing marks the largest biotech IPO on the Hong Kong stock market in 2025. With an issue price of HK$ 24.05 per share, Insilico Medicine opened at HK$35.00 per share, representing a market capitalization of approximately HK$ 19.51 billion.

Qiming Venture Partners is one of Insilico Medicine's most important institutional investors. Qiming Venture Partners led the Company's Series B financing round in 2019 and continued its support in subsequent Series C and D rounds, with an about 7 percent stake in Insilico Medicine before its IPO.

Founded in 2014, Insilico Medicine employs a business model based on the Pharma.AI platform, focuses on internal drug research and development through artificial intelligence. It has gradually expanded the application of Pharma. AI to more industries such as advanced materials, agriculture, nutritional products, and veterinary drugs. It has now efficiently built a pipeline portfolio covering over 30 innovative projects in a wide range of fields with extensive demands, such as oncology, immunology, fibrosis, and metabolism, and owns the world's most advanced first-in-class AI-based drugs.

To date, 13 of the world's top 20 pharmaceutical companies by revenue have entered into software platform collaborations with Insilico Medicine. Insilico Medicine has also reached licensing agreements on three pipelines with global drugmakers such as Exelixis and Menarini, bringing a potential revenue of USD2 billion for the company. The Company has also established drug R&D partnerships with other internationally renowned pharmaceutical firms including Sanofi, Lilly, and Shanghai Fosun Pharmaceutical (Group) Co., Ltd.

"Insilico is dedicated to extending human productive longevity and this listing provides us with more resources to advance our mission. Over the past few years, we set very clear industry benchmarks demonstrating that AI can help make drug discovery faster, cheaper, and deliver higher success rates in preclinical and early clinical development. We have validated the end-to-end capabilities of AI-empowered programs from novel target discovery to molecular generation, and then to preclinical and clinical stages. Going forward, we will continue to increase investment in our AI platform and innovative pipeline, accelerate the advancement of differentiated innovative programs into clinic, and bring truly accessible, affordable, and breakthrough treatment solutions to patients worldwide." said Alex Zhavoronkov, PhD, Founder and CEO, Chief Business Officer of Insilico Medicine.

"We invest in Insilico Medicine based on a simple belief that 'AI will profoundly change the pathway and efficiency of drug development.' We decided to invest in Insilico Medicine in 2019 because of its research in frontier areas when generative AI was not yet popularized. Now the value of Insilico Medicine in the field of AI pharmaceuticals is gradually being realized through preclinical validation and pipeline licensing. We expect AI to not only empower early-stage research and development but also effectively accelerate the clinical stage process in the future to enable new drugs to benefit patients earlier," Dr. Chen Kan, Partner and Healthcare Co-Lead at Qiming Venture Partners, said.

About Qiming Venture Partners

Qiming Venture Partners was founded in 2006. Currently, Qiming Venture Partners manages eleven US Dollar funds and seven RMB funds with $9.5 billion in capital raised. Since our establishment, we have invested in outstanding companies in the Technology and Healthcare industries at the early and growth stages.

Since our debut, we have backed over 580 fast-growing and innovative companies. Over 210 of our portfolio companies have achieved exits through IPOs at the NYSE, NASDAQ, HKEX, Shanghai Stock Exchange, or Shenzhen Stock Exchange, or through M&A or other means. There are also over 80 portfolio companies that have achieved unicorn or super unicorn status.

Many of our portfolio companies are today's most influential firms in their respective sectors, including Xiaomi, Meituan, Bilibili, Zhihu, Roborock, Hesai Technology, UBTech, WeRide, HyperStrong, Insta360, Unisound, Gan & Lee Pharmaceuticals, Tigermed, Zai Lab, CanSino Biologics, Schrödinger, APT Medical, Sanyou Medical, AmoyDx, SinocellTech, Insilico Medicine (SEHK:03696), AusperBio, Yuanxin Technology, Medilink Therapeutics, LaNova Medicines, zai, StepFun, among many others.

SOURCE Qiming Venture Partners

21%

more press release views with

Request a Demo

License out/inIPO

18 Jul 2025

In June 2025, several breakthrough drugs received their first global approvals and market launches, marking significant advances in therapeutic innovation.

1. Genakumab (Firsekibart)

Firsekibart (Genakumab), developed by Changchun Genescience Pharmaceutical, is a fully human monoclonal antibody targeting interleukin-1β (IL-1β). It functions as an IL-1β inhibitor and was approved in China on June 30, 2025, for the treatment of gouty arthritis, especially in patients who are intolerant or unresponsive to NSAIDs or colchicine. The approval addresses a significant gap in long-acting, targeted anti-inflammatory therapies in China, offering a new option for over 14 million gout patients.

Gout is a chronic inflammatory disease caused by urate crystal deposition in joints. It is often referred to as the "king of pain" due to its severe and recurrent attacks. The underlying pathology involves activation of the NLRP3 inflammasome in macrophages, leading to a surge in IL-1β secretion, which triggers a cascade of inflammatory responses.

Firsekibart is a fully human anti-IL-1β monoclonal antibody that binds specifically to IL-1β and neutralizes its biological activity, blocking receptor interaction and suppressing inflammation at its source. This mechanism allows for rapid pain relief during acute attacks and sustained anti-inflammatory effects during intercritical periods, helping reduce recurrence rates and inflammatory flares during urate-lowering therapy. It may also offer systemic benefits for cardiorenal and metabolic comorbidities.

The approval was based on data from a randomized, double-blind, multicenter Phase III trial involving 313 patients with acute gout flares. Results showed that a single dose of Firsekibart provided pain relief within 6 hours, with a comparable 72-hour efficacy to compound betamethasone. The primary endpoint—the difference in VAS pain score at 72 hours—was -3.32 mm (95% CI: -7.56, 0.91), confirming non-inferiority.

Notably, Firsekibart demonstrated superior performance in preventing recurrence:

·Median time to first gout recurrence: not reached (Firsekibart) vs. 45 days (steroid group)

·Risk reduction in first recurrence within 6 months: up to 90%

·Recurrence reduction over 24 weeks: 87%, with 85.3% of patients remaining recurrence-free—the best result among its class.

The drug was well tolerated, with a treatment-related adverse event rate similar to the control group and no serious adverse events reported. Future indications for Firsekibart may include cardiovascular inflammation, osteoarthritis, diabetes, obesity, and tumor microenvironment modulation, suggesting broad clinical potential.

2. Gemcitabine (AVGEMSI, D07001-Softgel)

Gemcitabine, a small-molecule chemotherapeutic agent originally developed by FUJIFILM Corporation, received its first approval in the United States on June 27, 2025, for the treatment of multiple malignancies, and was granted orphan drug designation.

Gemcitabine is a pyrimidine-based antitumor drug with a mechanism of action similar to cytarabine (Ara-C). It is activated intracellularly by deoxycytidine kinase (dCK) and metabolized by cytidine deaminase. Once metabolized, its active form incorporates into DNA during the G1/S phase, inhibiting DNA synthesis. Unlike cytarabine, gemcitabine also inhibits ribonucleotide reductase, decreasing intracellular dNTP pools and further impairing DNA replication. Additionally, it inhibits deoxycytidine deaminase, reducing the degradation of its own active metabolites—effectively self-potentiating its efficacy.

These pharmacodynamic features give gemcitabine a broader antitumor spectrum than cytarabine, and it has demonstrated efficacy across multiple solid tumors, including metastatic breast cancer, non-small cell lung cancer (NSCLC), ovarian cancer, and pancreatic adenocarcinoma.

Clinically, gemcitabine has become a standard first-line therapy for locally advanced and metastatic NSCLC. A pivotal Phase III trial in advanced NSCLC patients showed that the gemcitabine + cisplatin combination significantly improved overall survival compared to cisplatin alone:

·Median OS: 10.7 months (combination) vs. 8.6 months (cisplatin monotherapy)

·The difference was statistically significant (p < 0.05)

Gemcitabine’s safety profile has been extensively studied. While myelosuppression, gastrointestinal discomfort, and fever are common adverse effects, they are generally manageable and acceptable, confirming the drug’s suitability for routine clinical use in oncology.

3. Mazdutide (IBI362)

Mazdutide (also known as IBI362) is a synthetic polypeptide drug co-developed by Eli Lilly & Co. and Innovent Biologics. It acts as a dual agonist of GLP-1 and GIP receptors, designed for the treatment of endocrine and metabolic disorders. On June 24, 2025, it received its first market approval in China, with an indication for obesity and overweight. The drug also shows promising potential in other metabolic conditions such as type 2 diabetes, obstructive sleep apnea, non-alcoholic steatohepatitis (NASH), and various forms of heart failure.

Mazdutide exerts synergistic effects by simultaneously activating GLP-1 and glucagon (GCG) receptors. Activation of GLP-1 receptors delays gastric emptying, suppresses appetite, and enhances satiety, leading to reduced caloric intake. Activation of the GCG receptor promotes lipolysis and increases energy expenditure, thereby enhancing weight loss. This dual mechanism provides superior efficacy compared to single-target agents, positioning Mazdutide as a representative of next-generation metabolic regulators.

Clinical studies in Chinese populations have demonstrated significant weight loss and good safety. The pivotal Phase III GLORY-1 trial, published in the New England Journal of Medicine (NEJM), enrolled 610 Chinese subjects who were overweight or obese. After 48 weeks of once-weekly subcutaneous injections, the 4 mg group experienced a mean weight loss of 11.00%, and the 6 mg group lost 14.01%, compared to 0.3% in the placebo group. Notably, nearly 50% of patients in the 6 mg group achieved at least 15% body weight reduction, with effects evident as early as week 32. Beyond weight reduction, Mazdutide also improved glycemic control, lipid profiles, and blood pressure, making it particularly beneficial for Chinese patients with metabolic syndrome.

In terms of safety, Mazdutide was well tolerated. The most common adverse events were mild to moderate gastrointestinal symptoms, including nausea, vomiting, and diarrhea, which mostly occurred during early treatment and resolved over time. The once-weekly injection regimen enhances patient adherence and supports long-term disease management.

4. Tetravalent Influenza Vaccine

Developed by Fosun Apexvac (Dalian) Biopharmaceutical Co., Ltd., the tetravalent split inactivated influenza vaccine was first approved in China on June 17, 2025, for the prevention of influenza virus infection. The vaccine is produced using internationally standardized embryonated egg-based manufacturing techniques, free from antibiotics and preservatives, and provides broad protection by inducing immunity against four different influenza virus strains.

Influenza is an acute respiratory infectious disease caused by influenza viruses. Due to the virus’s high genetic variability and broad host range, it spreads easily among humans, resulting in 3–5 million severe cases and 290,000–650,000 deaths globally each year. The World Health Organization (WHO) emphasizes that vaccination is the most effective method for influenza prevention, especially for high-risk individuals and their close contacts.

This tetravalent vaccine contains inactivated antigens from four influenza strains: two A subtypes (e.g., H1N1 and H3N2) and two B lineages. The viruses are chemically split to release key antigens, such as hemagglutinin (HA) and neuraminidase (NA), which trigger immune responses. Upon administration, antigen-presenting cells (e.g., dendritic cells) process these viral antigens and present them to helper T cells, which in turn activate B cells to produce strain-specific antibodies—especially anti-HA antibodies capable of neutralizing the virus. The vaccine also induces memory B and T cells, enabling rapid immune responses upon future exposure to similar strains.

5. 13-Valent Pneumococcal Polysaccharide Conjugate Vaccine (CRM197, TT)

The 13-valent pneumococcal polysaccharide conjugate vaccine, developed by CanSino Biologics, was first approved in China on June 17, 2025, for the prevention of Streptococcus pneumoniae infections. This multivalent conjugate vaccine targets 13 distinct pneumococcal serotypes responsible for pneumonia, meningitis, septicemia, and other invasive diseases.

The vaccine functions by covalently linking capsular polysaccharide antigens of pneumococcal serotypes to protein carriers such as CRM197 (a non-toxic diphtheria toxin mutant) and tetanus toxoid (TT). This conjugation converts the normally T cell-independent polysaccharides into T cell-dependent antigens, capable of eliciting a stronger and longer-lasting immune response, particularly in infants and young children.

After administration, the conjugated antigens are taken up and processed by antigen-presenting cells, then presented to CD4+ T helper cells, which activate B cells to generate serotype-specific antibodies. Additionally, the vaccine promotes the formation of memory B cells, providing long-term protection. This mechanism enables the immune system to mount a robust defense against the 13 pneumococcal serotypes, significantly reducing the risk of invasive pneumococcal disease (IPD). The vaccine is especially effective in pediatric populations, offering enhanced and durable immunity.

6. Garadacimab

Garadacimab (formerly CSL312) is a fully human recombinant IgG4/λ monoclonal antibody developed by CSL Behring LLC. It was approved in the United States on June 16, 2025, for the treatment of hereditary angioedema (HAE), with additional potential applications in diseases such as idiopathic pulmonary fibrosis.

HAE is a rare but potentially life-threatening genetic disorder that affects approximately 1 in 50,000 individuals. It is characterized by recurrent, painful episodes of swelling (angioedema), which can involve the larynx, gastrointestinal tract, and other critical areas. Garadacimab exerts its therapeutic effect by selectively binding to and inhibiting coagulation factor XIIa (FXIIa), a key initiator in the contact activation system involved in inflammatory and coagulation cascades.

By targeting FXIIa, Garadacimab helps reduce pathological processes such as vascular leakage and inflammation, which are central to HAE pathogenesis. FXII is particularly important in HAE patients due to its role in activating the kallikrein-kinin system, leading to bradykinin-mediated angioedema. Garadacimab features an unusually long CDR-H3 loop, allowing specific binding to the β-chain of FXIIa, thereby blocking its protease activity and downstream pro-inflammatory and pro-coagulant pathways.

The FDA approval was supported by efficacy and safety data from the pivotal Phase III VANGUARD trial (NCT04656418) and its open-label extension (NCT04739059). VANGUARD evaluated Garadacimab as a routine prophylactic treatment in 64 patients aged ≥12 years with Type I or II HAE, all of whom experienced ≥2 attacks during the run-in period and discontinued prior prophylactic therapies. Participants were randomized 3:2 to receive 400 mg loading dose followed by 200 mg monthly Garadacimab (n=39) or matched placebo (n=25) for 6 months. On-demand medication for breakthrough attacks was allowed.

At baseline, 59.4% of participants had ≥3 HAE attacks per month (mean: 3.07/month in the Garadacimab group vs. 2.52/month in the placebo group). Garadacimab significantly reduced attack frequency and demonstrated a favorable safety profile, reinforcing its potential as a long-term preventive therapy for HAE. Additional trials in fibrotic and inflammatory diseases are ongoing, highlighting its broad therapeutic promise.

7. Taletrectinib

Taletrectinib, also known by its compound name ADCT-601 or AnHeart Therapeutics' ROS1 inhibitor, is a next-generation small molecule tyrosine kinase inhibitor (TKI) targeting ROS1-positive non-small cell lung cancer (NSCLC). Co-developed by AnHeart Therapeutics (Hangzhou) and Innovent Biologics, Taletrectinib received FDA approval on June 11, 2025, for the treatment of locally advanced or metastatic ROS1-positive NSCLC.

ROS1 gene rearrangements are oncogenic drivers found in approximately 1–2% of NSCLC cases and are associated with poor response to standard chemotherapy. Taletrectinib is a highly potent and selective ROS1 TKI, designed to inhibit the aberrant signaling caused by ROS1 fusions, which drive tumor growth in affected patients. Notably, it also shows efficacy against certain resistance mutations, offering therapeutic options for both treatment-naïve patients and those with acquired resistance to first-generation ROS1 inhibitors like crizotinib.

FDA approval was based on results from two pivotal Phase II global multicenter studies, TRUST-I and TRUST-II, which evaluated the efficacy and safety of Taletrectinib in ROS1-positive advanced NSCLC across both treatment-naïve and pretreated populations. Patients received 600 mg orally once daily, and endpoints included objective response rate (ORR), duration of response (DoR), progression-free survival (PFS), and intracranial response in patients with brain metastases.

Taletrectinib demonstrated robust clinical activity in both cohorts. It achieved high ORR, prolonged PFS, and demonstrated notable intracranial efficacy, making it a strong candidate for managing CNS-involved disease. Safety outcomes were favorable, with manageable adverse events, supporting its use as a next-generation targeted therapy for ROS1-positive NSCLC. Its ability to overcome resistance mechanisms further positions it as a valuable treatment option for patients who have progressed on earlier ROS1-targeted agents.

8. Clesrovimab

Clesrovimab (MK-1654), developed by Merck Sharp & Dohme Corp., is a long-acting monoclonal antibody that received its first FDA approval on June 9, 2025, for the prevention of respiratory syncytial virus (RSV) infection.

Clesrovimab specifically targets the RSV fusion (F) protein, a critical viral surface protein required for viral entry into host cells. By binding with high affinity to the F protein, Clesrovimab not only blocks the fusion process between the virus and host cell membranes—thereby preventing viral entry—but also enhances the immune system’s ability to recognize and eliminate the virus. Importantly, since the F protein is highly conserved across all RSV subtypes, Clesrovimab exhibits broad-spectrum antiviral activity against a wide range of RSV strains.

As a passive immunization therapy, Clesrovimab’s extended half-life allows it to deliver direct, rapid, and long-lasting protection against RSV infection in healthy preterm infants, full-term infants, and high-risk infants. The antibody is designed to protect infants during their first RSV season against mild, moderate, and severe RSV disease. Data from the pivotal Phase 2b/3 CLEVER trial demonstrated that a single dose of Clesrovimab reduced medically attended RSV lower respiratory tract infections by 60.5% and hospitalizations due to RSV by 84.3% within 150 days post-treatment.

Further evidence from the SMART Phase 3 study validated Clesrovimab’s efficacy and safety in both preterm and full-term infants, as well as high-risk populations, where it showed superior performance compared to existing standard preventive therapies.

9. Amlodipine Besylate/Indapamide/Telmisartan

Amlodipine Besylate/Indapamide/Telmisartan, marketed as Widaplik, is a fixed-dose triple combination therapy developed by George Medicines Pty Ltd. It received its first FDA approval on June 5, 2025, for the treatment of hypertension. Widaplik is the first and currently only FDA-approved triple-combination product specifically designed for patients who may require multiple antihypertensive agents to achieve optimal blood pressure control.

Widaplik combines three active components, each with a distinct antihypertensive mechanism:

·Amlodipine, a calcium channel blocker, relaxes vascular smooth muscle by inhibiting calcium influx into cardiac and arterial wall cells.

·Telmisartan, an angiotensin II receptor blocker (ARB), prevents vasoconstriction and reduces fluid retention by blocking angiotensin II.

·Indapamide, a thiazide-like diuretic, promotes the excretion of sodium and water, further lowering blood pressure.

Approval was supported by two pivotal clinical studies:

Study 1 enrolled 295 patients with systolic hypertension who were either treatment-naïve or on monotherapy. Following a 2-week placebo run-in, patients were randomized to receive different doses of Widaplik or placebo. At week 4, both Widaplik doses significantly reduced home-measured systolic blood pressure compared to placebo (P < 0.0001), with most of the antihypertensive effect observed within the first two weeks.

Study 2 compared Widaplik to dual-component therapies. At week 12, Widaplik achieved superior reductions in home systolic blood pressure versus all dual-therapy arms (P < 0.0001). The effect was consistent across age, sex, and racial subgroups.

In terms of safety, Widaplik was generally well tolerated. The most common adverse events were symptomatic hypotension and electrolyte imbalances such as hyponatremia and hypokalemia.

Summary

June 2025 marked the approval and launch of several milestone new drugs in the global pharmaceutical landscape, representing significant advances across multiple therapeutic areas. From targeted precision therapies like Taletrectinib and Garadacimab, to multimodal combination regimens like Widaplik, and passive immunization agents such as Clesrovimab and Genakumab, to next-generation vaccines like the quadrivalent influenza vaccine and the 13-valent pneumococcal conjugate vaccine, these innovative products exemplify the synergistic potential of biologics and small molecules. Together, they are not only enhancing treatment efficacy across various diseases but are also shaping the future of personalized, effective, and sustainable medicine.

How to obtain the latest research advancements in the field of biopharmaceuticals?

In the Synapse database, you can keep abreast of the latest research and development advances in drugs, targets, indications, organizations, etc., anywhere and anytime, on a daily or weekly basis. Click on the image below to embark on a brand new journey of drug discovery!

21 Jun 2025

HONG KONG, China I June 20, 2025 I

Pneumonia is a form of acute respiratory infection, that is common in all age groups and can cause mild to life-threatening illness. It is also the single largest infectious cause of death in children worldwide.

According to the World Health Organization(WHO), pneumonia killed more than 808,000 children under the age of 5 in 2017, accounting for 15% of all deaths of children under 5 years. Notably, in China, non-invasive pneumococcal diseases(NIPD), result in approximately 550,000 cases annually, leading to around 6,000 deaths. Meanwhile, invasive pneumococcal diseases (IPD) are more severe, with over 7,200 cases of pneumococcal meningitis reported each year. The average treatment cost per case of IPD is approximately CNY 64,000, and the case-fatality rate exceeds 10%. Behind these stark numbers lie the heavy burdens on countless families and an urgent public health challenge.

Facing this challenge, CanSino Biologics Inc. (Stock Code: 688185.SH, 6185.HK, “CanSinoBIO” or “the Company”) has developed and launched its 13-valent pneumococcal conjugate vaccine, trade name “iPneucia®”, optimized for China’s local pneumococcal epidemiology, aiming to provide more precise and safer protection for Chinese children.

The main advantage of iPneucia® is its deep optimization based on China’s local epidemiological characteristics. Streptococcus pneumoniae is categorized into different serotypes based on polysaccharide structure and biochemical traits. However, not all serotypes pose the same threat; their pathogenicity and disease burden vary. Research indicates that serotypes 19F, 19A, 7F, and 3 are the four most burdensome for Chinese children, accounting for over 60% of cases. These serotypes are also characterized by high resistance and high risk of sequelae. Given these risks, iPneucia® is specifically designed to target these four high-risk serotypes, and clinical data show that the geometric mean concentration (GMC) of antibodies against these four serotypes in iPneucia® is significantly higher than in the control group. This targeted protection strategy greatly enhances the precision of prevention, reducing disease risks at the source.

The breakthrough of iPneucia® lies not only in its enhanced targeting serotypes protection effect, but also in its carrier technology. It pioneers a dual-carrier conjugate process that adopts CRM197 and tetanus toxoid(TT) as carrier proteins. This approach effectively avoids immune interference caused by excessive use of a single carrier and reduces the risk of immune suppression when co-administered with other vaccines, enhancing immunogenicity. Moreover, iPneucia® also adopts a more advanced carrier protein conjugation process, ensuring consistent polysaccharide antigen content across all serotypes, significantly reducing competition between components.

Notably, the process of using CRM197 carrier as carrier protein in iPneucia® does not require formaldehyde for detoxification, which improves vaccine safety. This is also supported by data from Menhycia, another CRM197-based vaccine developed by CanSinoBIO. Post-marketing surveillance data on adverse events following immunization (AEFI) for recipients of the Menhycia show a apparently decline in the incidence of AEFI, fever, and local induration..

In summary, iPneucia® offers precise protection by targeting key serotypes and innovative protein carrier technology, resulting in enhanced effectiveness while minimizing the risk of adverse reaction. It also utilize a mature production process that excludes phenol, further improving its safety profile. CanSinoBIO presents a superior option for preventing pneumococcal diseases in Chinese children.

As a leader in innovative vaccines, CanSinoBIO always dedicated to scientific research and exploration in vaccine development. The company strives to create innovative, high-quality, and affordable vaccines. CanSinoBIO is committed to tackling global health challenges and improving the health and well-being of children around the world.

CanSinoBIO, (688185.SH)(06185.HK),

https://www.cansinobio.com

SOURCE:

CanSinoBIO

VaccineDrug Approval

100 Deals associated with CanSino Biologics, Inc.

Login to view more data

100 Translational Medicine associated with CanSino Biologics, Inc.

Login to view more data

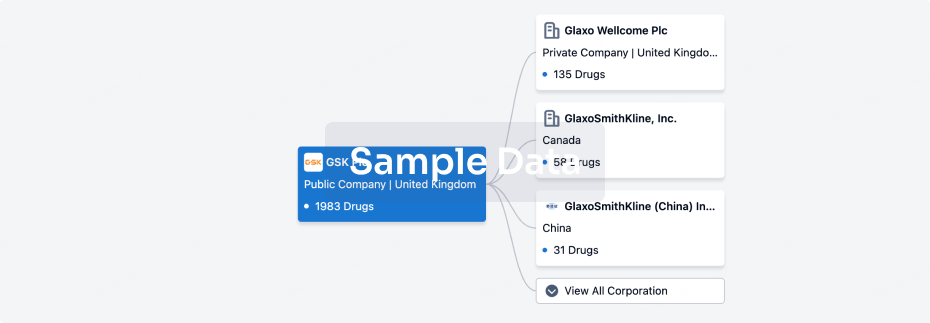

Corporation Tree

Boost your research with our corporation tree data.

login

or

Pipeline

Pipeline Snapshot as of 21 Feb 2026

The statistics for drugs in the Pipeline is the current organization and its subsidiaries are counted as organizations,Early Phase 1 is incorporated into Phase 1, Phase 1/2 is incorporated into phase 2, and phase 2/3 is incorporated into phase 3

Preclinical

10

2

IND Approval

Phase 1

6

2

Phase 2

Phase 3

1

2

NDA/BLA

Approved

7

6

Other

Login to view more data

Current Projects

Login to view more data

Deal

Boost your decision using our deal data.

login

or

Translational Medicine

Boost your research with our translational medicine data.

login

or

Profit

Explore the financial positions of over 360K organizations with Synapse.

login

or

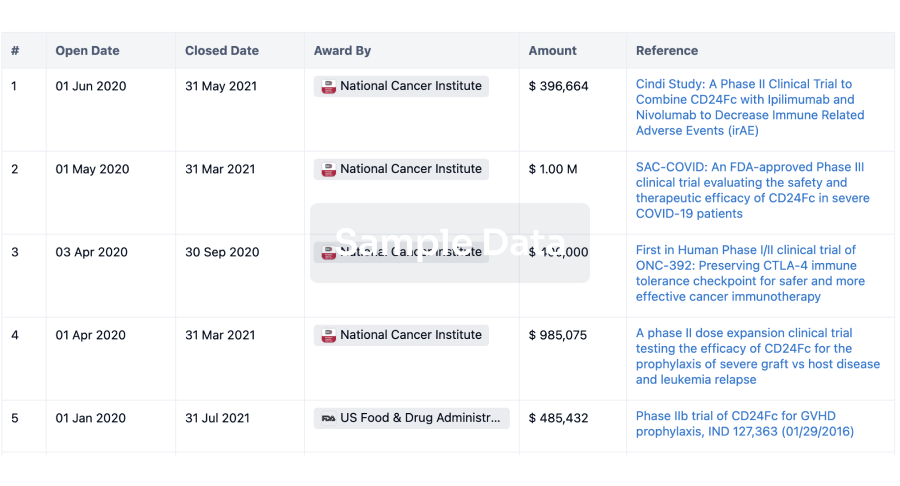

Grant & Funding(NIH)

Access more than 2 million grant and funding information to elevate your research journey.

login

or

Investment

Gain insights on the latest company investments from start-ups to established corporations.

login

or

Financing

Unearth financing trends to validate and advance investment opportunities.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free