Request Demo

Last update 08 May 2025

ScpA

Last update 08 May 2025

Basic Info

Synonyms- |

Introduction- |

Related

1

Drugs associated with ScpATarget |

Mechanism ScpA inhibitors [+1] |

Active Org.- |

Originator Org. |

Active Indication- |

Inactive Indication |

Drug Highest PhasePending |

First Approval Ctry. / Loc.- |

First Approval Date20 Jan 1800 |

100 Clinical Results associated with ScpA

Login to view more data

100 Translational Medicine associated with ScpA

Login to view more data

0 Patents (Medical) associated with ScpA

Login to view more data

168

Literatures (Medical) associated with ScpA01 Jul 2025·Metabolic Engineering

Engineering Halomonas bluephagenesis for pilot production of terpolymers containing 3-hydroxybutyrate, 4-hydroxybutyrate and 3-hydroxyvalerate from glucose

Article

Author: Yang, Shimao ; Jer, Ng Wuh ; Zheng, Shuang ; Hu, Qitiao ; Chen, Guo-Qiang ; Sun, Simian ; Zhang, Zhongnan ; Wu, Fuqing ; Wu, Qiong ; Xu, Geyuan ; He, Hongtao

15 Apr 2025·The Journal of Infectious Diseases

Serological Responses to Target Streptococcus pyogenes Vaccine Antigens in Patients With Proven Invasive β-Hemolytic Streptococcal Infections

Article

Author: Smith, Rosemary ; Fulurija, Alma ; Taggart, Michael ; Morici, Michael ; Levy, Avram ; Langworthy, Kristyn ; Hui, Siong ; Knight, Daniel R ; Raby, Edward ; Manning, Laurens

01 Feb 2025·International Journal of Pharmaceutics

An in-situ forming controlled release soft hydrogel-based C5a peptidase drug delivery system to treat psoriasis

Article

Author: Duarte, Francisco ; Tecza, Malgorzata ; McGourty, Kieran ; Patel, Pratikkumar ; Bhattacharjee, Promita ; Hudson, Sarah ; Gedi, Vinayakumar

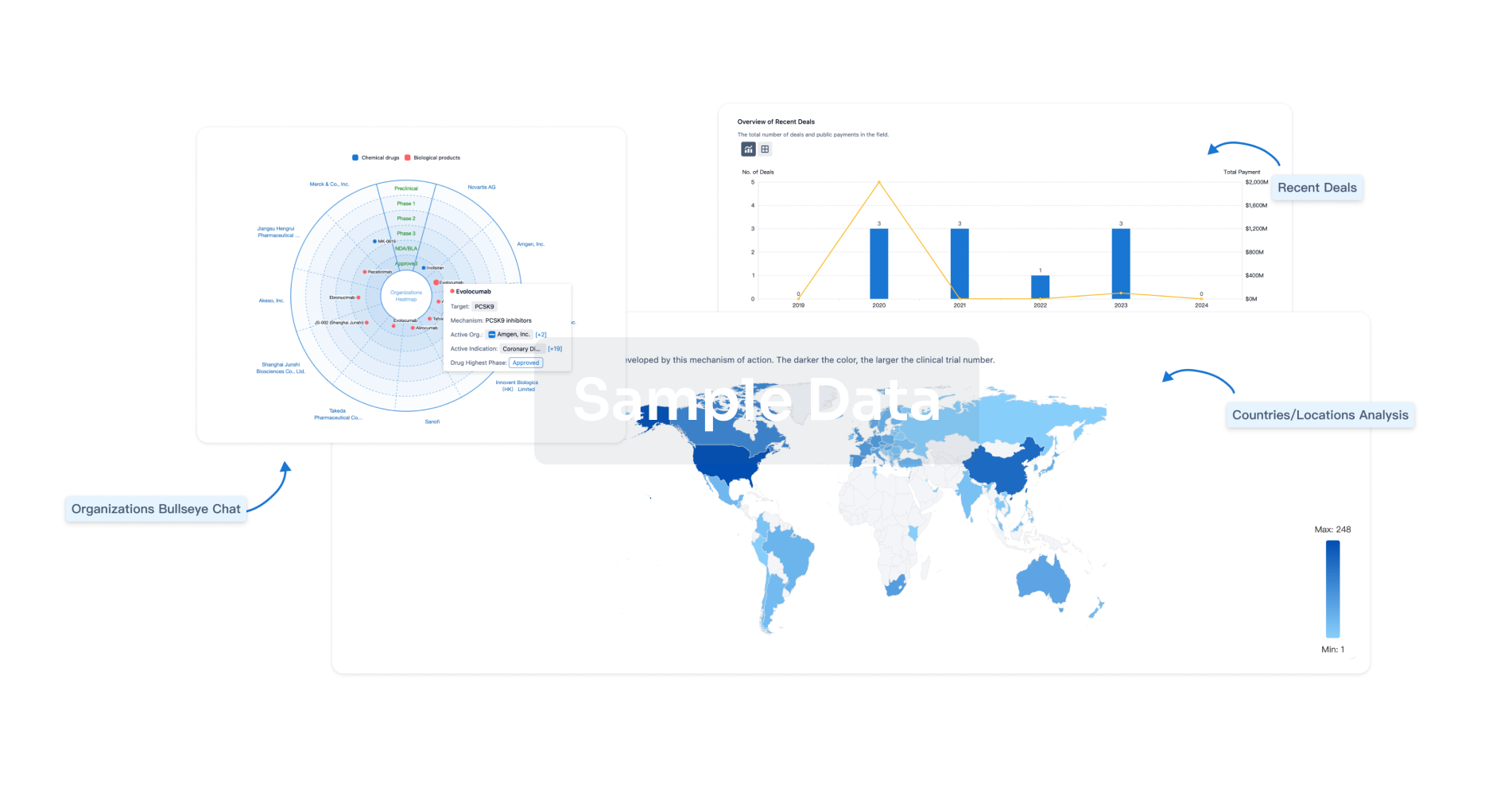

Analysis

Perform a panoramic analysis of this field.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free