Request Demo

Last update 16 Oct 2025

Phorbol 12-myristate 13-acetate

Last update 16 Oct 2025

Overview

Basic Info

Drug Type Small molecule drug |

Synonyms Phorbol myristate acetate, PMA, Tetradecanoylphorbol acetate + [5] |

Target |

Action stimulants |

Mechanism PKCδ stimulants(Protein kinase C delta stimulants), PKCε stimulants(protein kinase C epsilon stimulants) |

Therapeutic Areas |

Active Indication- |

Originator Organization |

Active Organization- |

Inactive Organization |

License Organization- |

Drug Highest PhaseDiscontinuedPhase 2 |

First Approval Date- |

Regulation- |

Login to view timeline

Structure/Sequence

Molecular FormulaC36H56O8 |

InChIKeyPHEDXBVPIONUQT-RGYGYFBISA-N |

CAS Registry16561-29-8 |

Sequence Code 76476

Related

18

Clinical Trials associated with Phorbol 12-myristate 13-acetateJPRN-jRCT2042230026

A multicenter, single-arm study to evaluate the safety and feasibility of PMA System for chronic total occlusion of coronary arteries

Start Date26 Jul 2023 |

Sponsor / Collaborator- |

ChiCTR2200060885

The effects of Theta-burst Transcranial Magnetic Stimulation over Contralesional Premotor Area and Contralesional Primary Motor Cortex on Post-stroke Spasticity in Patients with Severe Hemiplegia

Start Date25 Jun 2022 |

Sponsor / Collaborator- |

NCT05433051

A Comparison of Two Protocol for Maxillary Molar Intrusion Buccal Miniscrew and TPA Versus Vertical Holding Appliance Randomized Controlled Trial

this study is to compare the dental and skeletal changes caused by the intrusion of maxillary first molars buccal miniscrew and TPA versus vertical holding appliance using lateral cephalometry.

Start Date10 Apr 2022 |

Sponsor / Collaborator |

100 Clinical Results associated with Phorbol 12-myristate 13-acetate

Login to view more data

100 Translational Medicine associated with Phorbol 12-myristate 13-acetate

Login to view more data

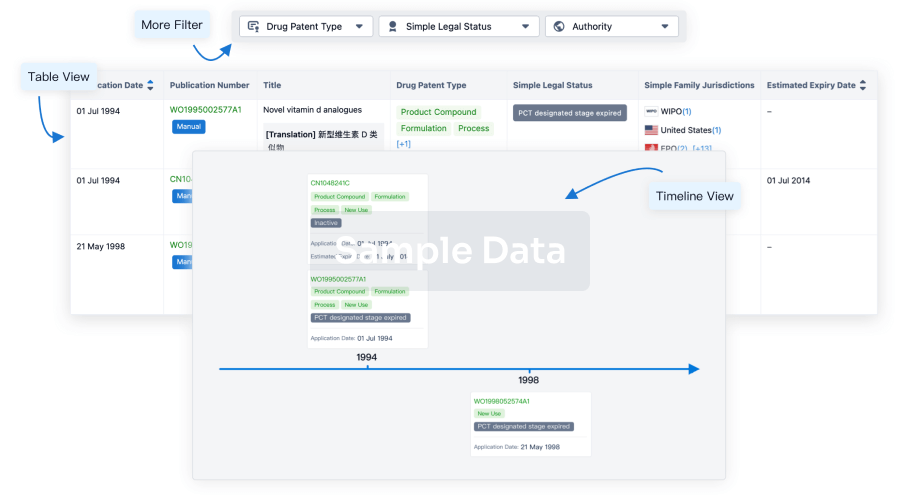

100 Patents (Medical) associated with Phorbol 12-myristate 13-acetate

Login to view more data

36,309

Literatures (Medical) associated with Phorbol 12-myristate 13-acetate01 Dec 2025·MOLECULAR BIOLOGY REPORTS

Effect of FLT3 ligand on the gene expression of TIM-3, HIF1-α, and TNF-α in an acute myeloid leukemia cell line

Article

Author: Kazemi-Sefat, Nazanin Atieh ; Heidari, Fatemeh ; Feizollahi, Parisa ; Gerdabi, Sajjad ; Ebtekar, Masoumeh ; Pourfathollah, Ali Akbar

BACKGROUND:

Acute Myeloid Leukemia (AML) pathogenesis is driven by the dysregulation of various cell signaling pathways, including the FMS-Like Tyrosine Kinase 3 (FLT3) pathway and its ligand (FLT3L). These pathways play a critical role in promoting cell survival, proliferation, and resistance to apoptosis, contributing to leukemogenesis. In this study, we investigated the effects of FLT3L on the expression of key genes associated with immune regulation, hypoxia, and inflammation-TIM-3, HIF-1α, and TNF-α-in the THP-1 cell line, a well-established model for AML research.

METHODS:

THP-1 cells were cultured under standard conditions and treated with varying concentrations of FLT3L, alongside PMA as a positive control. Quantitative RT-PCR was employed to measure the expression levels of TIM-3, HIF-1α, and TNF-α genes after 48 h of treatment.

RESULTS:

Our findings demonstrated that specific concentrations of FLT3L significantly upregulated the expression of TIM-3, HIF-1α, and TNF-α in THP-1 cells. This suggests that FLT3L not only influences cell proliferation and survival but also modulates pathways related to immune evasion, hypoxia adaptation, and inflammatory responses, which are hallmarks of leukemia progression.

CONCLUSION:

These results highlight the pivotal role of FLT3L in regulating the expression of genes associated with AML pathogenesis, particularly those involved in hypoxia (HIF-1α), immune checkpoint regulation (TIM-3), and inflammation (TNF-α). The findings underscore the potential of targeting the FLT3 pathway as a therapeutic strategy in AML. Further studies are warranted to elucidate the underlying molecular mechanisms and explore their clinical implications for improving patient outcomes.

01 Dec 2025·INTERNATIONAL IMMUNOPHARMACOLOGY

Timosaponin AIII from Anemarrhena asphodeloides binds and inhibits S100A8-mediated neutrophil infiltration and NET formation ameliorates MASH

Article

Author: Lan, Xintian ; Luo, Haoming ; Zhu, Ming ; Fang, Xiaoxue ; Zhao, Xinyi ; Li, Jing ; Ju, Jingxin ; Bai, Yunfan ; Xie, Ruishi

OBJECTIVE:

This study aimed to identify the active compound from Anemarrhena asphodeloides Bge. (AA) that ameliorates metabolic dysfunction-associated steatohepatitis (MASH) and to elucidate its mechanism of action.

METHODS:

A screening was conducted using a high-cholesterol diet-induced zebrafish MASH model. The active ingredients and compounds were subsequently evaluated in a feed-induced mice model of methionine-choline deficiency (MCD) and a primary neutrophil model induced by PMA. Immune cell depletion, network pharmacology, transcriptomics, molecular docking, and surface plasmon resonance (SPR) were utilized to identify targets and pathways.

RESULTS:

Timosaponin AIII (TA3) from AA n-butanol extract could significantly improve the pathological characteristics of MASH. In mice, TA3 reduced lipid accumulation, liver injury, inflammation, and neutrophil infiltration. Neutrophil depletion studies confirmed that TA3 primarily acts by targeting neutrophils. It inhibited neutrophil extracellular trap (NET) formation, an effect validated in PAD4-/- mice. Integrated analyses identified S100A8 as a key target; TA3 bound directly to S100A8, disrupting the S100A8/A9 heterodimer and subsequently inhibiting the TLR4/NF-κB pathway and reducing ROS production. These effects were abolished upon S100A8 knockdown.

CONCLUSION:

TA3's ability to ameliorate MASH may be associated with the binding of S100A8, which attenuates NETosis and neutrophil infiltration, and inhibits the activation of the TLR4/NF-κB pathway and ROS production.

01 Dec 2025·MOLECULAR BIOLOGY REPORTS

MARCKS N-terminal sequence-derived inhibitor peptides impair monocytic ROS production and migration via MARCKS-independent effects

Article

Author: Kühl, Friederike ; Wriede, Lena Sofie ; Kopper, Jana Lea ; Lichtinghagen, Ralf ; Welz, Bastian ; Brand, Korbinian ; Huber, René

Abstract:

Background:

Myristoylated alanine-rich C kinase substrate (MARCKS) is a versatile unstructured protein involved in numerous cellular processes and associated with various diseases. In this study, the effect of MARCKS’ N-terminal sequence-derived inhibitor peptides MANS (“myristoylated N-terminal sequence”) and BIO-11006 on monocytic ROS production and migration was assessed.

Methods and results:

Stimulation of calcitriol-differentiated monocytic THP-1 cells with PMA, opsonized (ops.) E. coli, ops. S. aureus, and ops. zymosan led to considerable ROS production (as determined using a chemiluminescence-based assay), an effect significantly reduced in THP-1-derived MARCKS knock-out (KO) cells that were generated with the CRISPR/Cas9 technique. MANS similarly inhibited ROS production in monocytic THP-1 and PLB-985 cells as well as primary human monocytes induced by various stimuli, while BIO-11006 predominantly affected PMA-induced ROS levels. TNF preincubation enhanced monocytic ROS production, but was not able to compensate for MANS treatment or MARCKS deficiency. Unexpectedly, an inhibition of ROS formation by both inhibitor peptides could also be observed in MARCKS KO cells, indicating a target-independent effect of MANS and BIO-11006 at least in MARCKS-deficient monocytic cells. Comparable negative effects of MANS in both WT and KO cells could also be observed when monocytic migration was assessed in transwell assays.

Conclusion:

Our data suggest that MARCKS inhibitor peptides MANS and (to a lesser extent) BIO-11006 are able to inhibit MARCKS-associated cellular processes in monocytic cells by MARCKS-independent mechanisms.

15

News (Medical) associated with Phorbol 12-myristate 13-acetate18 Mar 2025

CHAPEL HILL, N.C., March 18, 2025 /PRNewswire/ -- SonoVascular, Inc., a clinical stage medical device company focused on bringing to market its SonoThrombectomy™ System for venous thromboembolism (VTE), a novel treatment solution intended to provide better outcomes for millions of patients suffering from deep vein thrombosis (DVT) and pulmonary embolism (PE), has successfully completed an initial set of eight cases in patients with DVT in its First-In-Human (FIH) study.

DVT is a condition that occurs when blood clots form in the deep veins of the leg, restricting blood flow back to the heart and causing pain and swelling. Additionally, if part of the clot breaks off it can travel through the bloodstream to the lungs, causing a PE which can be life threatening. To treat these conditions, the SonoThrombectomy System delivers ultrasound energy and microbubbles directly to the clot through the RESONATOR™ Catheter, inducing microbubble-mediated cavitation, which mechanically breaks down the clot. Additionally, a very low dose of tPA is infused in combination with the microbubbles through the catheter to further improve clot breakdown. The System is designed to treat VTE more safely and effectively, and at a lower cost to the health care system than currently approved therapies.

SonoThrombectomy treatment was highly effective in the first eight cases of the FIH study, as all cases achieved a complete (100%) Marder score reduction as assessed by an independent core laboratory. Additionally, significant improvements from baseline in Villalta score, revised Venous Clinical Severity Score, and Numeric Pain Rating Scale scores were observed at 30-day follow-up, and there were no device-related adverse events, major bleeding, or deaths.

"We are very encouraged by the initial cases in our FIH clinical study." said Daniel Estay, Founder and Chief Executive Officer of SonoVascular. "Thus far, our investigators have observed complete thrombus resolution, no blood loss, and no evidence of adverse affects on the vein wall or venous valves or other safety concerns. Enrollment in the FIH study is ongoing and planned to be completed by the end of Q2 2025. We are honored that Dr. William Marston presented our initial clinical findings at the 2025 annual meeting of the American Venous Forum on February 19th in Atlanta, Georgia."

William Marston, MD, Professor of Surgery at the University of North Carolina at Chapel Hill School of Medicine and Past President of the American Venous Forum, remarked:

"The results obtained thus far in SonoVascular's FIH study demonstrate the SonoThrombectomy System has the potential to become a disruptive technology that would effectively overcome the shortcomings of available therapies for the treatment of DVT. As a vascular surgeon and researcher who has treated patients suffering from DVT for over 25 years, I find that despite improvements in our ability to treat these patients, currently available devices still have significant challenges and limitations. In the initial cases, the SonoThrombectomy System has demonstrated its ability to eliminate intravenous clot in a single treatment session with no blood loss and with preservation of venous valves. The System is not limited by the presence of previously implanted filters or stents and is highly steerable for treatment of specific areas of residual thrombus.

These initial cases suggest that the SonoThrombectomy System is able to eliminate clot with a gentler approach that does not cause blood loss and preserves vessel and valve integrity. This System has the potential to be a revolutionary technology and address critical limitations with current interventional devices and techniques for treatment of DVT."

About Venous Thromboembolism

Venous thromboembolism is a condition that occurs when a blood clot forms in a vein. As many as 900,000 VTE events occur each year in the United States.1 VTE includes DVT and PE. DVT occurs when a blood clot forms in a deep vein, usually in the lower leg, thigh or pelvis. The most serious complication of DVT happens when a part of the clot breaks off and travels through the bloodstream to the lungs, causing a blockage called PE. If the clot is large, it can stop blood from reaching the lungs and can be fatal. One-third to one-half of people who have a DVT will have long-term complications caused by damage to the valves in the vein called post-thrombotic syndrome (PTS).2 In some cases, PTS symptoms can be so severe that a person becomes disabled. PE can be life-threatening, with 10-30% of individuals dying within one month of diagnosis.3

About SonoVascular, Inc.

SonoVascular is a clinical-stage medical device company that has developed the SonoThrombectomy system. SonoThrombectomy is a novel and highly differentiated ultrasound facilitated, thrombolytic enhanced thrombectomy system for venous and arterial thrombosis that utilizes microbubble-mediated cavitation as a core enabling mechanical mechanism of action to more safely and effectively treat VTE. It is a cathlab-based solution designed to maximize the reduction of clot burden, eliminate blood loss and vessel trauma, and harness the benefit of low dose/duration thrombolytic without bleeding risks. SonoVascular is headquartered in Chapel Hill, NC.

For more information, visit .

Contact:

SonoVascular, Inc.

Daniel Estay

Founder and Chief Executive Officer

[email protected]

1 Gregson J, Kaptoge S, Bolton T, et al. Cardiovascular Risk Factors Associated With Venous Thromboembolism. JAMA Cardiol. 2019;4(2):163–173. doi:10.1001/jamacardio.2018.4537.

2 Wendelboe AM, Campbell J, McCumber M; Bratzler D; Ding K, Beckman M, Reyes N; Raskob G. The Design and Implementation of a New Surveillance System for Venous Thromboembolism using Combined Active and Passive Methods. American Heart Journal. 2015.

3 American Lung Association;

SOURCE SonoVascular, Inc.

WANT YOUR COMPANY'S NEWS FEATURED ON PRNEWSWIRE.COM?

440k+

Newsrooms &

Influencers

9k+

Digital Media

Outlets

270k+

Journalists

Opted In

GET STARTED

Clinical ResultAHAClinical Study

24 Feb 2025

Fourth Quarter Highlights:

Achieved revenue of $97.3 million in the fourth quarter of 2024 versus $93.7 million in the fourth quarter of 2023, an increase of 4% on a GAAP basis and 3% on a non-GAAP constant currency basis

Achieved revenue of $388.5 million for the full year of 2024 versus $354.0 million for the full year of 2023, an increase of 10% on a GAAP basis and 9% on a non-GAAP constant currency basis

Net loss was $(16.5) million, or $(0.39) per fully diluted share and non-GAAP net income was $0.2 million, or $0.00 per fully diluted share in the fourth quarter of 2024. For the full year, net loss was $(13.4) million, compared to a net loss of $(30.7) million in the 2023 fiscal year

Adjusted EBITDA increased 15% to $17.6 million in the fourth quarter of 2024 compared to $15.3 million in the fourth quarter of 2023. For the full year adjusted EBITDA increased 32% to $71.3 million

Generated $22.2 million of operating cash flow and $11.0 million of non-GAAP free cash flow for the full year of 2024

Granted Humanitarian Device Exemption (HDE) by the U.S. Food and Drug Administration (FDA) for the AMDS Hybrid Prosthesis

Submitted second module of the pre-market approval application (PMA) to the FDA for AMDS Hybrid Prosthesis

ATLANTA, Feb. 24, 2025 /PRNewswire/ --

Artivion, Inc. (NYSE: AORT), a leading cardiac and vascular surgery company focused on aortic disease, today announced financial results for the fourth quarter and year ended December 31, 2024.

"2024 was an excellent year for Artivion, marked by robust revenue and adjusted EBITDA growth, which enabled us to deliver positive free cash flow while making significant strides in key clinical and regulatory initiatives. Revenue growth in the fourth quarter was driven by year-over-year growth in On-X of 10%, stent grafts of 10%, and BioGlue of 8% all compared to the fourth quarter of 2023. On a constant currency basis, year-over-year, On-X, stent grafts, and BioGlue grew 10%, 8%, and 7%, respectively. We also saw continued revenue strength in Latin America which grew 26% both in the fourth quarter and for the full year 2024 on a constant currency basis compared to last year." said Pat Mackin, Chairman, President, and Chief Executive Officer.

Mr. Mackin continued, "In addition to our commercial results, we were also thrilled to receive a Humanitarian Device Exemption from the FDA for AMDS. This enables us to deliver our groundbreaking, life-saving technology to patients while we continue to work with the FDA toward PMA approval."

Mr. Mackin added, "Q4 was a continuation of the outstanding progress we saw this year on multiple clinical and regulatory fronts. First, new clinical data from our AMDS PERSEVERE trial was presented in a Late-Breaking Science session at the Society of Thoracic Surgeons. It demonstrated sustained benefit of AMDS out to one-year, including a 50% reduction in mortality at one-year as compared to the reference cohort. Second, we submitted our second module of the PMA application to the FDA for AMDS."

Mr. Mackin concluded, "Finally, I'd like to thank our team members for their dedication to mitigating the late November 2024 cybersecurity incident and maintaining our ability to continue serving our customers and their patients. Thanks to their hard work, we are operating at normal levels across the business, with any remaining inefficiencies expected to be resolved in the near-term. While our Q4 revenues were negatively impacted, we do not expect this incident to meaningfully impact our business for the full year 2025. Looking ahead for 2025, we remain confident in our ability to execute on our best-in-class pipeline and drive sustained double-digit revenue growth and adjusted EBITDA growth at twice the pace of constant currency revenue growth."

Fourth Quarter 2024 Financial Results

Total revenues for the fourth quarter of 2024 were $97.3 million, an increase of 4% on a GAAP basis and 3% on a non-GAAP constant currency basis, both compared to the fourth quarter of 2023.

Net loss for the fourth quarter of 2024 was $(16.5) million, or $(0.39) per fully diluted common share, compared to net loss of $(4.0) million, or $(0.10) per fully diluted common share for the fourth quarter of 2023. Non-GAAP net income for the fourth quarter of 2024 was $0.2 million, or $0.00 per fully diluted common share, compared to non-GAAP net income of $4.6 million, or $0.11 per fully diluted common share for the fourth quarter of 2023. Non-GAAP net income for the fourth quarter of 2024 includes pretax losses related to foreign currency revaluation of $5.4 million.

Full Year 2024 Financial Results

Total revenues for 2024 were $388.5 million, an increase of 10% on a GAAP basis and 9% on a non-GAAP constant currency basis, both compared to the full year of 2023.

Net loss for 2024 was $(13.4) million, or $(0.32) per fully diluted common share, compared to net loss of $(30.7) million, or $(0.75) per fully diluted common share for the full year of 2023. Non-GAAP net income for the full year of 2024 was $10.8 million, or $0.25 per fully diluted common share, compared to non-GAAP net income of $8.4 million, or $0.20 per fully diluted common share for the full year of 2023. Non-GAAP net income for the full year of 2024 includes pretax losses related to foreign currency revaluation of $5.4 million.

2025 Financial Outlook

Artivion expects revenues for the full year 2025 to be in the range of $420 to $435 million, representing growth of 10% to 14% on a constant currency basis compared to 2024. At current exchange rates, the Company expects currency to negatively impact year-over-year as reported revenue growth rates by approximately 2%.

Additionally, Artivion expects adjusted EBITDA growth of between 18% and 28% for the full year 2025 compared to 2024, resulting in an expected range of $84 to $91 million for 2025.

The Company's financial performance for 2025 and future periods is subject to the risks identified below.

Non-GAAP Financial Measures

This press release contains non-GAAP financial measures, including non-GAAP revenue, non-GAAP net income, EBITDA, adjusted EBITDA, non-GAAP general, administrative, and marketing expenses, and free cash flows. Investors should consider this non-GAAP information in addition to, and not as a substitute for, financial measures prepared in accordance with US GAAP. In addition, this non-GAAP financial information may not be the same as similar measures presented by other companies. The Company's non-GAAP revenues are adjusted for the impact of changes in currency exchange. The Company's non-GAAP net income, EBITDA, adjusted EBITDA, general, administrative, and marketing, and free cash flows results primarily exclude (as applicable) depreciation and amortization expense, interest income and expense, non-cash compensation expense, loss or gain on foreign currency revaluation, income tax expense or benefit, business development, integration, and severance income or expense, loss on extinguishment of debt, non-cash interest expense, capital expenditures, and other non-recurring items.

The Company generally uses non-GAAP financial measures to facilitate management's review of the operational performance of the Company and as a basis for strategic planning. Company management believes that these non-GAAP presentations provide useful information to investors regarding unusual non-operating transactions, the operating expense structure of the Company's existing and recently acquired operations, without regard to its on-going efforts to acquire additional complementary products and businesses, and the transaction and integration expenses incurred in connection with recently acquired and divested product lines, and the operating expense structure excluding fluctuations resulting from foreign currency revaluation and non-cash compensation expense. The Company believes it is useful to exclude certain expenses and revenues because such amounts in any specific period may not directly correlate to the underlying performance of its business operations or can vary significantly between periods as a result of factors such as impact of recent acquisitions, non-cash expense related to amortization of previously acquired tangible and intangible assets, and any related adjustments to their carrying values. The Company has adjusted for the impact of changes in currency exchange from certain revenues to evaluate comparable product growth rates on a constant currency basis. The Company does, however, expect to incur similar types of expenses and currency exchange impacts in the future, and this non-GAAP financial information should not be viewed as a statement or indication that these types of expenses will not recur. Company management encourages investors to review the Company's consolidated financial statements and publicly filed reports in their entirety, including the reconciliation of GAAP to non-GAAP financial measures.

The Company's adjusted EBITDA expectations for fiscal 2025 exclude potential charges or gains that may be recorded during the fiscal year, relating to, among other things, non-cash compensation; business development, integration, and severance income or expense; loss on extinguishment of debt; and foreign currency revaluations. The Company does not attempt to provide reconciliations of forward-looking adjusted EBITDA to the comparable GAAP measure because the impact and timing of these potential charges or gains are inherently uncertain and difficult to predict and are unavailable without unreasonable efforts. In addition, the Company believes such reconciliations would imply a degree of precision and certainty that could be confusing to investors. Such items could have a material impact on GAAP measures of the Company's financial performance.

Webcast and Conference Call Information

The Company will hold a teleconference call and live webcast on February 24, 2025, at 4:30 p.m. ET to discuss the results, followed by a question-and-answer session. To participate in the conference call dial 201-689-8261 a few minutes prior to 4:30 p.m. ET. The teleconference replay will be available approximately one hour following the completion of the event and can be accessed by calling (toll free) 877-660-6853 or 201-612-7415. The conference number for the replay is 13749878.

The live webcast and replay can be accessed by going to the Investors section of the Artivion website at and selecting the heading Webcasts & Presentations.

About Artivion, Inc.

Headquartered in suburban Atlanta, Georgia, Artivion, Inc., is a medical device company focused on developing simple, elegant solutions that address cardiac and vascular surgeons' most difficult challenges in treating patients with aortic diseases. Artivion's four major groups of products include: aortic stent grafts, surgical sealants, On-X mechanical heart valves, and implantable cardiac and vascular human tissues. Artivion markets and sells products in more than 100 countries worldwide. For additional information about Artivion, visit our website, .

Forward-Looking Statements

Statements made in this press release that look forward in time or that express management's beliefs, expectations, or hopes are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Such forward-looking statements reflect the views of management at the time such statements are made. These statements include, but are not limited to, our beliefs and expectations about our revenue, year-over-year growth and growth drivers, earnings, currency impacts, and other financial measures and related information; our anticipated capital needs and capital structure; our beliefs about our competitive advantages and market opportunities; our expected product mix; anticipated quarterly fluctuations in our business; the timeline for regulatory approval for AMDS and other products; the benefits of receiving the Humanitarian Device Exemption and Breakthrough Designation for AMDS; our expected geographies and timeframes for commercializing our products; that our revenues for the full year 2025 will be in the range of $420 to $435 million, representing revenue growth of between 10% to 14% compared to 2024 on a constant currency basis; that we expect, at current exchange rates, a negative 2% currency impact on the 2025 full year revenues; our beliefs and expectations about the impact of the November 2024 cybersecurity incident; and that we expect non-GAAP adjusted EBITDA to increase between 18% and 28% for the full year 2025 compared to 2024, resulting in non-GAAP adjusted EBITDA in the range of $84 to $91 million in 2025. These forward-looking statements are subject to a number of risks, uncertainties, estimates and assumptions that may cause actual results to differ materially from current expectations, including, but not limited to, the unpredictability of the timing and outcome of regulatory decisions and other regulatory developments; risks relating to our international operations; the benefits anticipated from our new credit facility, the Ascyrus Medical LLC transaction and Endospan agreements, and our operational improvements in our tissue and stent graft business may not be achieved at all or at the levels we anticipate or had originally anticipated; the benefits anticipated from our clinical trials and regulatory approvals may not be achieved or achieved on our anticipated timelines; the uncertainty regarding potential unknown or future impacts of the November 2024 cybersecurity incident; and the benefits anticipated from our expansion into APAC and LATAM may not be achieved or achieved on our anticipated timelines. These risks and uncertainties include the risk factors detailed in our Securities and Exchange Commission filings, including our Form 10-K for the year ended December 31, 2024. Artivion does not undertake to update its forward-looking statements, whether as a result of new information, future events, or otherwise.

SOURCE Artivion, Inc.

WANT YOUR COMPANY'S NEWS FEATURED ON PRNEWSWIRE.COM?

440k+

Newsrooms &

Influencers

9k+

Digital Media

Outlets

270k+

Journalists

Opted In

GET STARTED

Financial StatementFast Track

10 Nov 2024

NEW YORK, Nov. 10, 2024 /PRNewswire/ -- Pomerantz LLP announces that a class action lawsuit has been filed against Allarity Therapeutics, Inc. ("Allarity" or the "Company") (NASDAQ: ALLR) and certain officers. The class action, filed in the United States District Court for the Southern District of New York, and docketed under 24-cv-06952, is on behalf of a class consisting of all persons and entities other than Defendants that purchased or otherwise acquired Allarity securities between May 17, 2022 and July 19, 2024, both dates inclusive (the "Class Period"), seeking to recover damages caused by Defendants' violations of the federal securities laws and to pursue remedies under Sections 10(b) and 20(a) of the Securities Exchange Act of 1934 (the "Exchange Act") and Rule 10b-5 promulgated thereunder, against the Company and certain of its top officials.

If you are a shareholder who purchased or otherwise acquired Allarity securities during the Class Period, you have until November 12, 2024 to ask the Court to appoint you as Lead Plaintiff for the class. A copy of the Complaint can be obtained at . To discuss this action, contact Danielle Peyton at [email protected] or 646-581-9980 (or 888.4-POMLAW), toll-free, Ext. 7980. Those who inquire by e-mail are encouraged to include their mailing address, telephone number, and the number of shares purchased.

[Click here for information about joining the class action]

Allarity is a clinical-stage biopharmaceutical company that develops oncology therapeutics using drug-specific companion diagnostics generated by its Drug Response Predictor technology. Allarity's drug candidates include, inter alia, Dovitinib, a pan-tyrosine kinase inhibitor for the treatment of renal cell carcinoma ("RCC"). The Company's companion diagnostic technology for Dovitinib is referred to as "DRP®-Dovitinib" or "Dovitinib-DRP."

On April 2, 2021, Allarity's predecessor parent corporation, Allarity Therapeutics A/S, announced that it had submitted a premarket approval application ("PMA") to the U.S. Food and Drug Administration ("FDA") for Dovitinib-DRP (the "Dovitinib-DRP PMA").

On December 22, 2021, Allarity issued a press release announcing that it had submitted a new drug application ("NDA") to the FDA seeking marketing approval for Dovitinib for the third-line treatment of RCC patients (the "Dovitinib NDA").

On February 18, 2022, Allarity issued a press release announcing that it had received Refusal to File ("RTF") letters from the FDA for the Dovitinib NDA and the Dovitinib-DRP PMA because "the NDA . . . and the PMA application . . . were not sufficiently complete to permit substantive reviews," noting that "the FDA's cited reasons for the RTF decision primarily include[d], but [we]re not limited to, that submitted clinical trial data do not enable a conclusion of efficacy based on non-inferiority data set" and that, because "the PMA and NDA were filed as related applications, the RTFs also apply to the DRP®-Dovitinib companion diagnostic."

Following these developments, Allarity continued to represent to investors and the market that it remained committed to pursuing the Dovitinib NDA and would work with the FDA to determine a clear regulatory path forward for resubmitting that application.

The Complaint alleges that, throughout the Class Period, Defendants made materially false and misleading statements regarding the Company's business, operations, and compliance policies. Specifically, Defendants made false and/or misleading statements and/or failed to disclose that: (i) Defendants had overstated the Dovitinib NDA's continued regulatory prospects; (ii) Allarity and three of its former officers had engaged in illegal, illicit, and/or otherwise improper conduct in connection with the Dovitinib NDA and/or the Dovitinib-DRP PMA; (iii) the foregoing misconduct subjected the Company to an increased risk of regulatory and/or governmental scrutiny and enforcement action, as well as significant legal, monetary, and reputational harm; (iv) following Allarity's announcement that it was, in fact, being investigated for wrongdoing in connection with the Dovitinib NDA and/or the Dovitinib-DRP PMA, the Company downplayed the substantial likelihood that an enforcement action would result from such investigation; and (v) as a result, the Company's public statements were materially false and misleading at all relevant times.

On June 29, 2022, Allarity issued a press release announcing that, "[e]ffective immediately," it had appointed Defendant James G. Cullem ("Cullem"), the Company's then-current Chief Business Officer, as its interim Chief Executive Officer ("CEO"), and Defendant Joan Y. Brown ("Brown"), the Company's then-current Director of Financial Reporting, as its interim Chief Financial Officer ("CFO"), and that its former CEO Defendant Steve R. Carchedi ("Carchedi") and former CFO Defendant Jens Knudsen ("Knudsen") had both purportedly "stepped down from those roles to pursue other opportunities."

The next day, Allarity disclosed in an U.S. Securities and Exchange Commission ("SEC") filing that Defendants Carchedi and Knudsen had either "resigned" or been "terminat[ed]" from all positions with the Company and its subsidiaries, while indicating that such "resignation" or "termination" may have been for cause, but without clarifying the same.

Following these disclosures, Allarity's stock price fell $0.31 per share, or 19.02%, to close at $1.32 per share on June 30, 2022.

On August 2, 2022, Allarity issued a press release announcing that "its Board of Directors has mandated a refocus of the Company's oncology pipeline strategy away from development of monotherapies" and, accordingly, "determined that advancing dovitinib as a monotherapy in adults is no longer commercially viable or in the best interests of its shareholders," citing "feedback that the Company recently received from the [FDA] from a Type C advisory meeting held in Q2 2022, regarding a potential Phase 3 clinical development path for dovitinib as a monotherapy third-line treatment for metastatic [RCC]." Accordingly, the Company would no longer pursue the Dovitinib NDA, which sought approval of Dovitinib as a monotherapy.

On this news, Allarity's stock price fell $0.045 per share, or 3.688%, to close at $1.175 per share on August 2, 2022.

On February 6, 2023, Allarity disclosed in an SEC filing that, "[i]n January 2023, we received a letter to produce documents from the SEC and that stated that the staff of the SEC is conducting an investigation . . . to determine if violations of the federal securities laws have occurred" in connection with "disclosures relating to submissions, communications and meetings with the FDA regarding our NDA for Dovitinib or Dovitinib-DRP."

On this news, Allarity's stock price fell $0.009 per share, or 3.8%, to close at $0.228 per share on February 6, 2023.

On December 11, 2023, Allarity disclosed in another SEC filing that, "[o]n December 8, 2023, [Defendant] Cullem was terminated as [CEO] of Allarity . . . and all other positions with the Company and its subsidiaries" and that Defendant Thomas Jensen had been appointed as the Company's new CEO on the same date.

On this news, Allarity's stock price fell $0.075 per share, or 13.37%, to close at $0.486 per share on December 11, 2023.

Then, on July 22, 2024, Allarity disclosed in yet another SEC filing that it had received a Wells Notice from the SEC's staff "relating to the Company's previously disclosed SEC investigation," advising that "[t]he Wells Notice relates to the Company's disclosures regarding meetings with the [FDA] regarding the Company's NDA for Dovitinib or Dovitinib-DRP, which was submitted to the FDA in 2021"; that, per the Company's understanding, "all conduct relating to the SEC Wells Notice occurred during or prior to fiscal year 2022"; and "that three of its former officers"—the same number of Company officers terminated during the Class Period—"received Wells Notices from the SEC relating to the same conduct."

On this news, Allarity's stock price fell $0.004 per share, or 2.38%, to close at $0.164 per share on July 22, 2024.

Finally, on September 13, 2024, Allarity disclosed in yet another SEC filing that, "[o]n September 12, 2024, the Company received a notice of resignation from [Defendant] Brown, its [CFO], effective September 12, 2024."

Pomerantz LLP, with offices in New York, Chicago, Los Angeles, London, Paris, and Tel Aviv, is acknowledged as one of the premier firms in the areas of corporate, securities, and antitrust class litigation. Founded by the late Abraham L. Pomerantz, known as the dean of the class action bar, Pomerantz pioneered the field of securities class actions. Today, more than 85 years later, Pomerantz continues in the tradition he established, fighting for the rights of the victims of securities fraud, breaches of fiduciary duty, and corporate misconduct. The Firm has recovered billions of dollars in damages awards on behalf of class members. See .

Attorney advertising. Prior results do not guarantee similar outcomes.

CONTACT:

Danielle Peyton

Pomerantz LLP

[email protected]

646-581-9980 ext. 7980

SOURCE Pomerantz LLP

WANT YOUR COMPANY'S NEWS FEATURED ON PRNEWSWIRE.COM?

440k+

Newsrooms &

Influencers

9k+

Digital Media

Outlets

270k+

Journalists

Opted In

GET STARTED

Executive ChangeNDA

100 Deals associated with Phorbol 12-myristate 13-acetate

Login to view more data

External Link

| KEGG | Wiki | ATC | Drug Bank |

|---|---|---|---|

| - | Phorbol 12-myristate 13-acetate | - | - |

R&D Status

10 top R&D records. to view more data

Login

| Indication | Highest Phase | Country/Location | Organization | Date |

|---|---|---|---|---|

| Myelodysplastic Syndromes | Phase 2 | United States | 01 Jan 2013 | |

| Refractory acute myeloid leukemia | Phase 2 | United States | 01 Mar 2011 | |

| Relapsing acute myeloid leukemia | Phase 2 | United States | 01 Mar 2011 |

Login to view more data

Clinical Result

Clinical Result

Indication

Phase

Evaluation

View All Results

| Study | Phase | Population | Analyzed Enrollment | Group | Results | Evaluation | Publication Date |

|---|

Phase 2/3 | 120 | (Group1: IV t-PA and Normothermia) | wpifmszgai = pafrlgiuha pwddzmhiev (yeeznzfuez, mhsfqqgqdx - zogphkgsje) View more | - | 05 Apr 2017 | ||

hypothermia and anti-shivering treatment (Group 2 : IV t-PA and Hypothermia and Anti-shivering Treatment) | cxzbendkwv = bxxplkwvtf cdrpfrcsal (dcvcmnppmo, bdsoimhygh - vbpnntbqcp) View more | ||||||

Phase 2 | 1 | zyggcflvbt(gplbpwyidz) = dcguczhtqu ijotikkthi (sgyqittaer, uccvangtbk - pblzowfzhq) View more | - | 22 Jun 2015 | |||

Phase 2 | 112 | TNK (TNK 0.1 mg/kg) | nmxusfwcvx = edmwhxchpo zczdponsmw (jfvkksdkhy, rhpvjkcifu - hafwyohifj) View more | - | 19 Jan 2015 | ||

TNK (TNK 0.25 mg/kg) | nmxusfwcvx = fernxmyrcu zczdponsmw (jfvkksdkhy, bdgzxldaij - lwgpjzrstl) View more |

Login to view more data

Translational Medicine

Boost your research with our translational medicine data.

login

or

Deal

Boost your decision using our deal data.

login

or

Core Patent

Boost your research with our Core Patent data.

login

or

Clinical Trial

Identify the latest clinical trials across global registries.

login

or

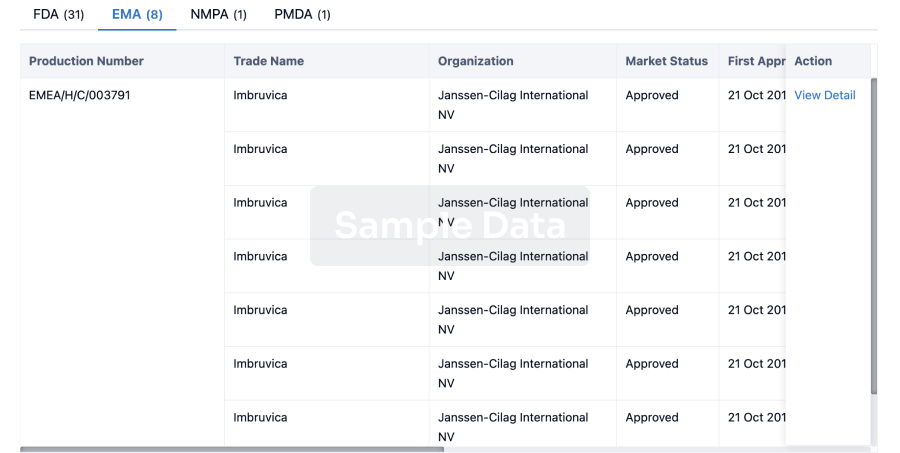

Approval

Accelerate your research with the latest regulatory approval information.

login

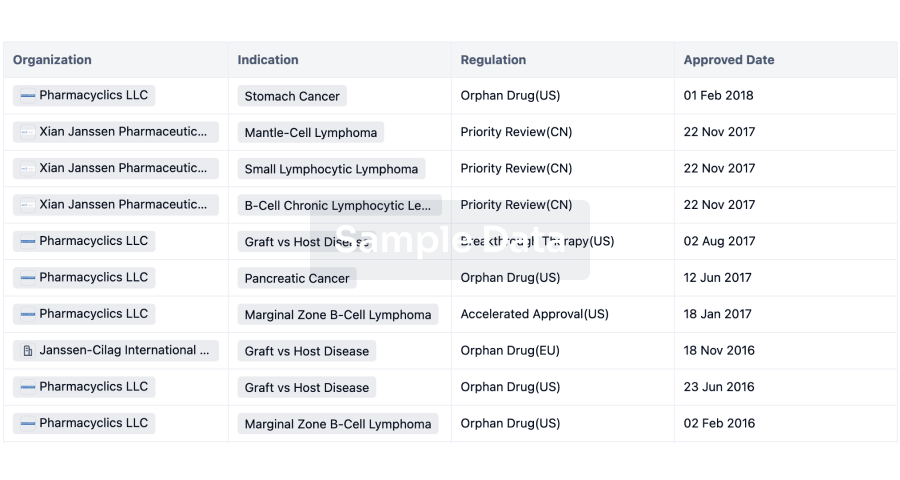

or

Regulation

Understand key drug designations in just a few clicks with Synapse.

login

or

AI Agents Built for Biopharma Breakthroughs

Accelerate discovery. Empower decisions. Transform outcomes.

Get started for free today!

Accelerate Strategic R&D decision making with Synapse, PatSnap’s AI-powered Connected Innovation Intelligence Platform Built for Life Sciences Professionals.

Start your data trial now!

Synapse data is also accessible to external entities via APIs or data packages. Empower better decisions with the latest in pharmaceutical intelligence.

Bio

Bio Sequences Search & Analysis

Sign up for free

Chemical

Chemical Structures Search & Analysis

Sign up for free